Anchoring slide rail (continued) – FlexLink X45 (43 мм) Тех. обслуживание User Manual

Page 16

16

Maintenance

Anchoring slide rail (continued)

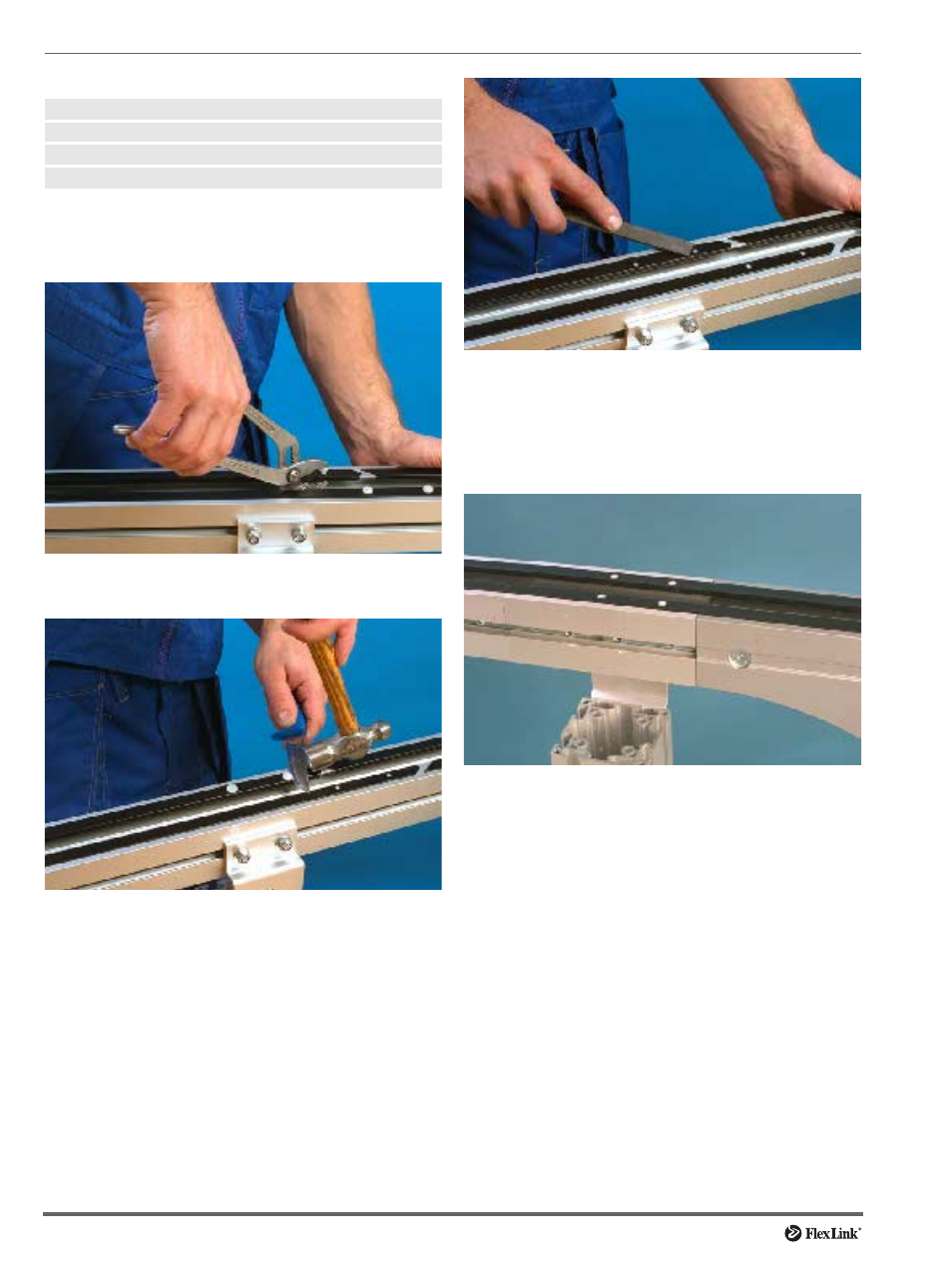

Method 2: Using plastic screws

An alternative to aluminium rivets is to use plastic screws

XLAG 5:

Mounting:

Pliers/screwdriver

Knife

Hammer

Plastic screws

XLAG 5

1 Press or screw the screws into the holes using a pair

of pliers or a screwdriver.

2 Cut off the screw heads by using a knife and a ham-

mer. The cut should be made away from the joint, in

the direction of chain travel.

3 Make sure the slide rail surface is smooth and that

screws do not protrude over the surface of the slide

rail. If the surface should be uneven, file the edges

smooth.

Check both top and underneath surface of slide rail for

protruding plastic or metal.

4 Keep a distance of approximately 30 mm between

screws and idler unit. This is in case the idler unit has

to be removed after conveyor system assembly.

- X45H (43 мм) Тех. обслуживание XS (45 мм) Тех. обслуживание XL (65 мм) Тех. обслуживание X85 (85 мм) Тех. обслуживание XH (105 мм) Тех. обслуживание XK (105 мм) Тех. обслуживание X180 (182 мм) Тех. обслуживание X300 (300 мм) Тех. обслуживание XW (300–1200 мм) Тех. обслуживание X45E (макс. 250 г) Тех. обслуживание XL (макс. 3 кг) Тех. обслуживание X85 (макс. 10 кг) Тех. обслуживание XK (макс. 30 кг) Тех. обслуживание