Part 1 - transmitter installation, Product identification, General – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 8

8

06-TTM-UM-00158 8/2012

Locate the transmitter within the length of transducer cable

that was supplied with the TFXL system. If this is not possible,

it is recommended that the cable be exchanged for one that

is of proper length. Both transducer cables must be of the

same length.

NOTE: The transducer cable carries low level, high frequency

signals. In general, it is not recommended to add additional

cable to the cable supplied with the DTTN, DTTH, DTTS or

DTTC transducers. If additional cable is required, contact the

factory to arrange an exchange for a transducer with the

appropriate length of cable. Cables to 990 feet (300 meters)

are available. To add cable length to a transducer, the cable

must be the same type as utilized on the transducer. Twinaxial

cables can be lengthened with like cable to a maximum

overall length of 100 feet (30 meters). Coaxial cables can be

lengthened with RG59 75 Ohm cable and BNC connectors to

990 feet (300 meters).

If the transmitter will be subjected to a wet environment, it is

recommended that the cover remain closed after confi gura-

tion is completed. The faceplate of the TFXL is watertight, but

avoid letting water collect on it. A sealed cord grip or NEMA

4 conduit connection should be used where cables enter the

enclosure. Holes not used for cable entry should be sealed

with plugs.

To access terminal strips for electronic connectors, loosen

the four screws in the display lid and remove the cover. The

terminals where the transducers connect are located under-

neath the display. To connect transducers, remove the four

screws that secure the display and carefully move it out of

the way. Do not over stress the ribbon cable located between

the display and the microprocessor circuit boards.

PRODUCT IDENTIFICATION

The serial number and complete model number of each

TFXL are located on the side of the instrument enclosure.

Should technical assistance be required, please provide the

Customer Service Department

with this information.

PART 1 - TRANSMITTER

INSTALLATION

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument is stored

or re-shipped. Inspect the equipment and carton for damage.

If there is evidence of shipping damage, notify the carrier

immediately.

The enclosure should be mounted in an area that is conve-

nient for servicing, calibration or for observation of the LCD

readout (if equipped).

1) Locate the transmitter within the length of transducer

cables supplied. If this is not possible, it is recom-

mended that the cable be exchanged for one that is

of proper length. To add cable length to a transducer,

the cable must be the same type as utilized on the

transducer. Twinaxial cables can be lengthened with

like cable to a maximum overall length of 100 feet (30

meters). Coaxial cables can be lengthened with RG59

75 Ohm cable and BNC connectors to 990 feet (300

meters).

2) Mount the TFXL transmitter in a location:

~ Where little vibration exists.

~ That is protected from corrosive fl uids.

~ That is within the transmitters ambient temperature

limits -40 to +185° F (-40 to +85° C).

~ That is out of direct sunlight. Direct sunlight may

increase transmitter temperature to above the

maximum limit.

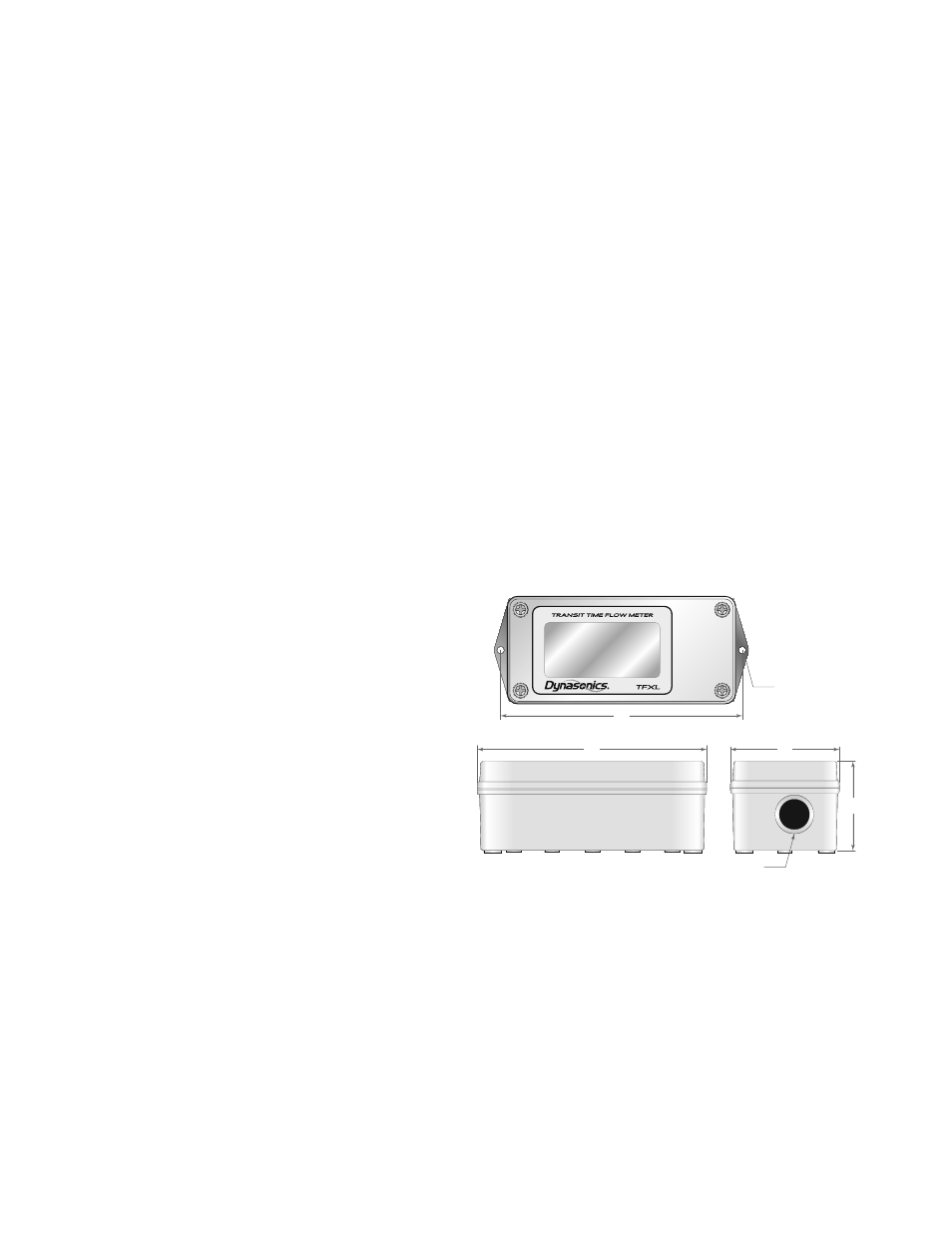

3) Mounting - Refer to Figure 1.2 for enclosure and

mounting dimension details. Ensure that enough room

is available to allow for door swing, maintenance and

conduit entrances. Secure the enclosure to a fl at surface

with two appropriate fasteners.

4) Conduit Holes - Conduit holes should be used where

cables enter the enclosure. Holes not used for cable

entry should be sealed with plugs.

NOTE: Use NEMA 4 [IP-65] rated fi ttings/plugs to maintain the

watertight integrity of the enclosure. Generally, the right side

conduit hole (viewed from front) is used for power, the bottom

conduit hole(s) for transducer connections.

2.57

(65.3)

6.66

(169.2)

7.01

(178)

0.875 (22.2) DIA

Conduit Hole

3.17

(80.5)

0.21(5.3) DIA

2 Mounting Holes

FIGURE 1.2 - ENCLOSURE DIMENSIONS

GENERAL

The remote mount TFXL is equipped with three conduit holes

located in the fl ow meter enclosure that should be suitable

for most installations. A sealed cord grip or NEMA 4 conduit

connection should be utilized to retain the NEMA 3 integrity

of the fl ow meter enclosure. Failure to do so will void the

manufacturer’s warranty and can lead to product failure.

The TFXL is housed in an insulating plastic enclosure that

does not provide continuity of bonding between fi eld wiring

conduit and the TFXL chassis or other conduits connected to

the enclosure.