Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 20

20

06-TTM-UM-00158 8/2012

Frequency

Transducers

Transmission

Modes

Pipe Size

and Type

2 MHz

All ½” thru 1½”

Small Pipe and

Tube

2” Tubing

Selected by

Firmware

Specifi c to

Transducer

1 MHz

2” ANSI Pipe and

Copper Tube

Selected by

Firmware

Specifi c to

Transducer

Standard and

High Temp

W, V, and Z

2” and Greater

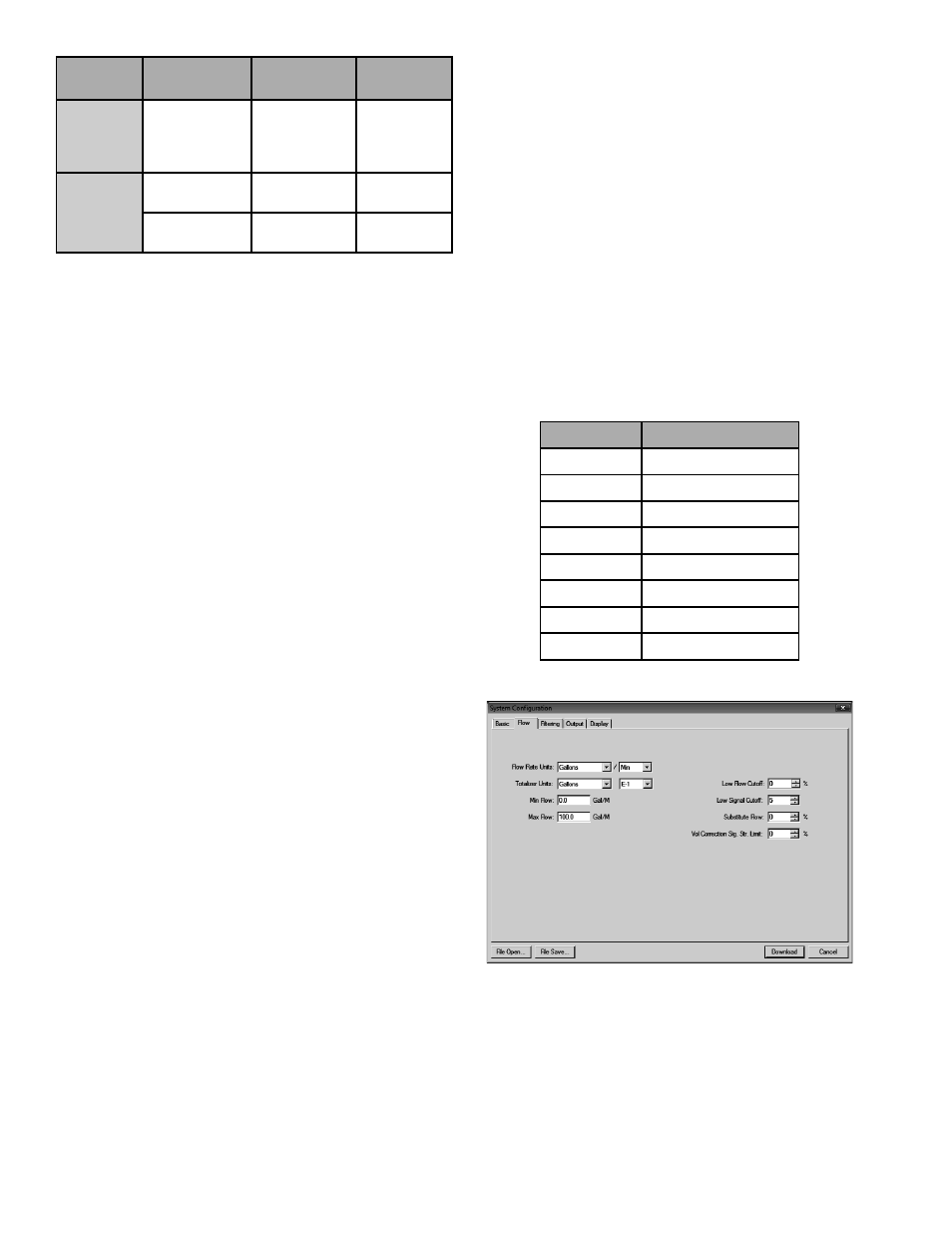

TABLE 4.1 - TRANSDUCER FREQUENCIES

Transducer Spacing is a value calculated by the TFXL

fi rmware that takes into account pipe, liquid, transducer

and mounting information. This spacing will adapt as these

parameters are modifi ed. The spacing is given in inches

for English units selection and millimeters for Metric. This

value is the lineal distance that must be between the trans-

ducer alignment marks. Selection of the proper transducer

mounting method is not entirely predictable and many times

is an iterative process.

NOTE: This setting only applies to DTTN, and DTTH

transducers.

Transducer Flow Direction allows the change of the

direction the meter assumes is forward. When mounting

TFXL meters with integral transducers, this feature allows

upstream and downstream transducers to be “electronically”

reversed, making upside down mounting of the display

unnecessary.

Pipe Material is selected from the pull-down list. If the pipe

material utilized is not found in the list, select Other and

enter the actual pipe material Sound Speed and Roughness

(much of this information is available at web sites such as

www.ondacorp.com/tecref_acoustictable.shtml

for pipe

relative roughness calculations.

Pipe O.D. and Wall Thickness are based on the physical

dimensions of the pipe on which the transducers will be

mounted. Enter this value in inches for English units or milli-

meters for Metric units.

NOTE: Charts listing popular pipe sizes have been included

in the

Appendix

of this manual. Correct entries for pipe O.D.

and pipe wall thickness are critical to obtaining accurate fl ow

measurement readings.

Liner Material is selected from the pull-down list. If the pipe

liner material utilized is not included in the list, select Other

and enter liner material Sound Speed and Roughness

(much of this information is available at web sites such as

www.ondacorp.com/tecref_acoustictable.shtml

. See

Page 40 for pipe liner relative roughness calculations.

Fluid Type is selected from a pull-down list. If the liquid is

not found in the list, select Other and enter the liquid Sound

Speed and Absolute Viscosity into the appropriate boxes.

The liquid’s Specifi c Gravity is required if mass measure-

ments are to be made.

FLOW TAB

Flow Rate Units are selected from the drop-down lists.

Select an appropriate rate unit and time from the two lists.

This entry also includes the selection of Flow Rate Interval

after the / sign.

Totalizer Units are selected from drop-down lists. Select

an appropriate totalizer unit and totalizer exponent. The

totalizer exponents are in scientifi c notation and permit the

eight digit totalizer to accumulate very large values before

the totalizer “rolls over” and starts again at zero. Table 4.2

illustrates the scientifi c notation values and their respective

decimal equivalents.

Exponent

Display Multiplier

E-1

Ч 0.1 (ч10)

E0

× 1 (no multiplier)

E1

× 10

E2

× 100

E3

× 1,000

E4

× 10,000

E5

× 100,000

E6

× 1,000,000

TABLE 4.2 - EXPONENT VALUES

FIGURE 4.4 - FLOW TAB

Min Flow is the minimum volumetric fl ow rate setting

entered to establish fi ltering parameters. Volumetric entries

will be in the Flow Rate Units. For unidirectional measure-

ments, set Min Flow to zero. For bidirectional measurements,

set Min Flow to the highest negative (reverse) fl ow rate

expected in the piping system.

Max Flow is the maximum volumetric fl ow rate setting

entered to establish fi ltering parameters. Volumetric entries