Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 22

22

06-TTM-UM-00158 8/2012

are examined by the Bad Data Rejection fi lter. The value is

entered as a percentage of actual fl ow rate.

For example, if the average fl ow rate is 100 GPM and the

Flow Filter Hysteresis is set to 5%, a fi lter window of 95-105

GPM is established. Successive fl ow measurements that are

measured within that window are recorded and averaged in

accordance with the Flow Filter Damping setting. Flow read-

ings outside of the window are held up in accordance with

the Bad Data Rejection fi lter.

Flow Filter MinHysteresis sets a minimum hysteresis

window that is invoked at sub 0.25 FPS (0.08 MPS) fl ow rates,

where the “of rate” Flow Filter Hysteresis is very small and

ineff ective. This value is entered in pico-seconds (ρ sec) and

is diff erential time. If very small fl uid velocities are to be

measured, increasing the Flow Filter MinHysteresis value

can increase reading stability.

Flow Filter Sensitivity allows confi guration of how fast the

Flow Filter Damping will adapt in the positive direction.

Increasing this value allows greater damping to occur faster

than lower values. Adaptation in the negative direction is not

user adjustable.

Bad Data Rejection is a value related to the number of

successive readings that must be measured outside of

the Flow Filter Hysteresis or Flow Filter MinHysteresis

windows before the fl ow meter will use that fl ow value.

Larger values are entered into Bad Data Rejection when

measuring liquids that contain gas bubbles, as the gas

bubbles tend to disturb the ultrasonic signals and cause

more extraneous fl ow readings to occur. Larger Bad Data

Rejection values tend to make the fl ow meter more sluggish

to rapid changes in actual fl ow rate.

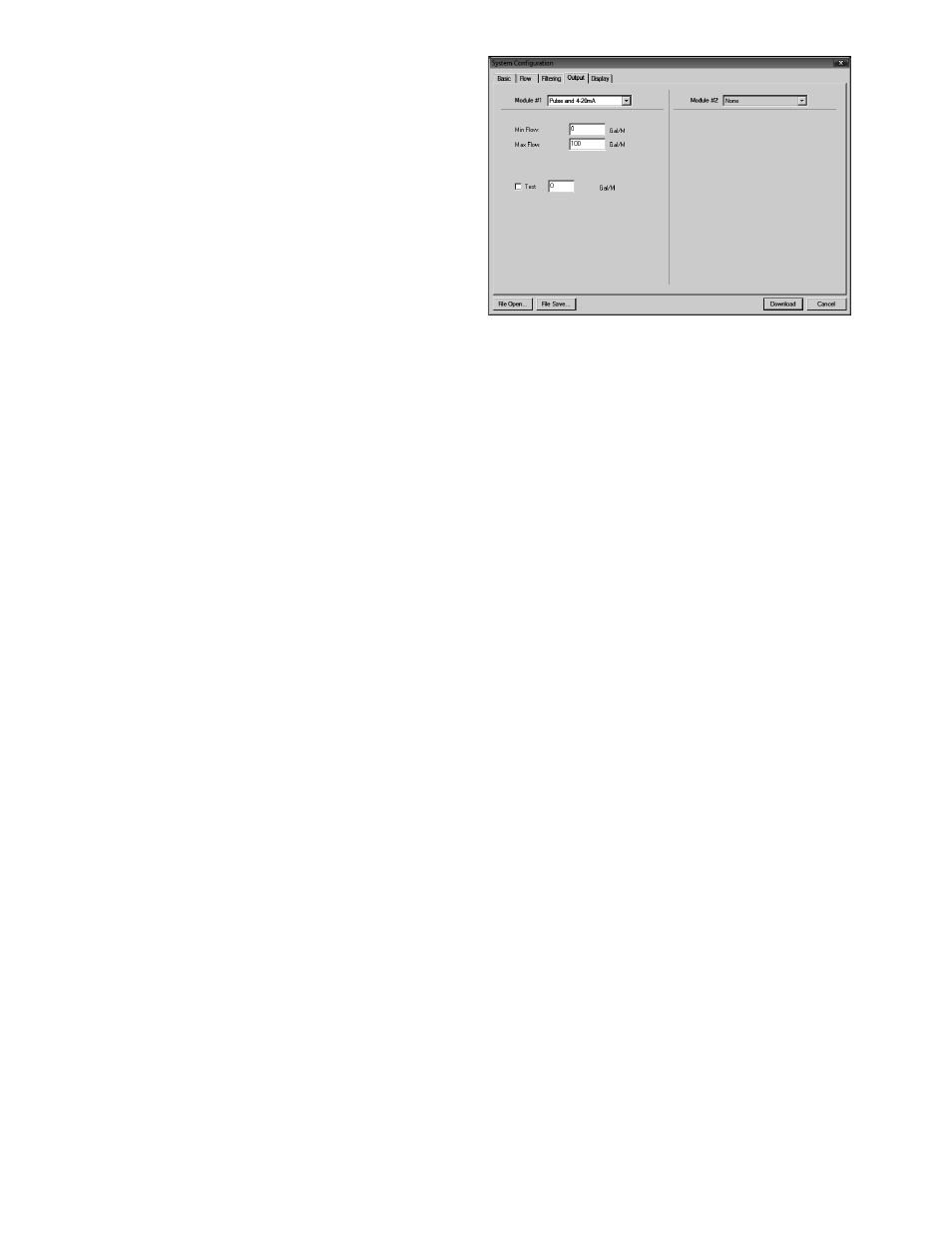

OUTPUT TAB

The entries made in the Output tab establish input and

output parameters for the fl ow meter. Select the appropriate

function from the pull-down menu and press the Down-

load button. When a function is changed from the factory

setting, a Confi guration error (1002) will result. This error

will be cleared by resetting the TFXL microprocessor from

the Communications/Commands/Reset Target button or

by cycling power on the TFXL fl ow meter. Once the proper

output is selected and the microprocessor is reset, calibration

and confi guration of the modules can be completed.

FIGURE 4.6 - OUTPUT TAB

CHANNEL 1 - 4-20 mA FREQUENCY

CONFIGURATION

NOTE: The 4-20 mA Output Frequency Menu applies to all

TFXL versions and is the only output choice for Channel 1.

The Channel 1 menu controls how the 4-20 mA output is

spanned for all TFXL models.

The Flow at 4 mA / 0 Hz and Flow at 20 mA / 1,000 Hz settings

are used to set the span for both the 4-20 mA output and the

0-1,000 Hz frequency output on the TFXL meter versions.

The 4-20 mA output is internally powered (current sourcing)

and can span negative to positive fl ow rates. This output

interfaces with virtually all recording and logging systems

by transmitting an analog current that is proportional to

system fl ow rate. Independent 4 mA and 20 mA span settings

are established in fi rmware using the fl ow measuring range

entries. These entries can be set anywhere in the - 40 to + 40

FPS (-12 to +12 MPS) range of the instrument. Resolution of

the output is 12-bits (4096 discrete points) and can drive up

to a 900 Ohm load. When powered by a DC supply, the load is

limited by the input voltage supplied to the instrument. See

Figure 3.1 for allowable loop loads.

Flow at 4 mA / 0 Hz

Flow at 20 mA / 1,000 Hz

The Flow at 4 mA / 0 Hz and Flow at 20 mA / 1,000 Hz entries

are used to set the span of the 4-20 mA analog output and

the frequency output on TFXL versions. These entries are

volumetric rate units that are equal to the volumetric units

confi gured as rate units and rate interval discussed on

Page 23.

For example, to span the 4-20 mA output from -100 GPM to

+100 GPM with 12 mA being 0 GPM, set the Flow at 4 mA / 0

Hz and Flow at 20 mA / 1,000 Hz inputs as follows: