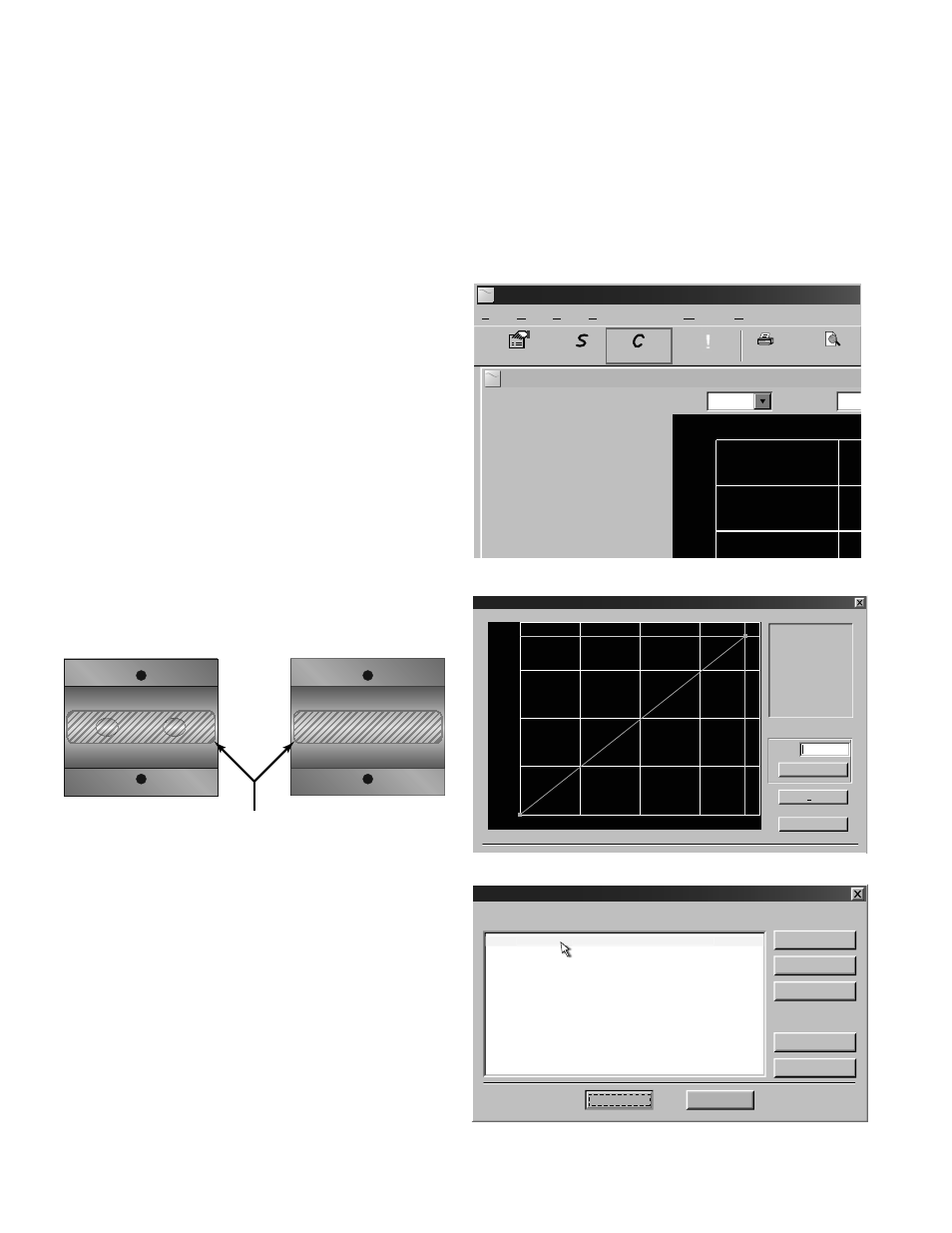

Figure 2.7 - data display screen, Figure 2.8 - calibration page 3 of 3, Figure 2.9 - calibration points editor – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 14

14

06-TTM-UM-00158 8/2012

NOTE: Mounting of high temperature transducers is similar to

mounting the DTTN transducers. High temperature installa-

tions require acoustic couplant that is rated not to “fl ow” at

the temperature that will be present on the pipe surface.

DTTS/DTTC SMALL PIPE TRANSDUCER AND

INTEGRAL MOUNT INSTALLATION

The small pipe transducers are designed for specifi c pipe

outside diameters. Do not attempt to mount a DTTS/DTTC or

integral mount transducer onto a pipe that is either too large

or too small for the transducer. Contact the manufacturer to

arrange for a replacement transducer that is the correct size.

DTTS/DTTC and integral installation consists of the

following steps:

1) Apply a thin coating of acoustic coupling grease to both

halves of the transducer housing where the housing

will contact the pipe. See Figure 2.6.

2) On horizontal pipes, mount the transducer in an orien-

tation such that the cable exits at ±45 degrees from the

side of the pipe. Do not mount with the cable exiting on

either the top or bottom of the pipe. On vertical pipes

the orientation does not matter. See Figure 2.2.

3) Tighten the wing nuts or “U” bolts so that the acoustic

coupling grease begins to fl ow out from the edges of

the transducer or from the gap between the transducer

halves. Do not over tighten.

4) If signal strength is less than 5, remount the transducer

at another location on the piping system.

1⁄16” (1.5 mm)

Acoustic Couplant

Grease

FIGURE 2.6 - APPLICATION OF ACOUSTIC COUPLANT —

DTTS/DTTC AND INTEGRAL TRANSDUCERS

NOTE: If a DTTS/DTTC small pipe transducer was purchased

separately from the TFXL meter, the following confi guration

procedure is required.

DTTS/DTTC Small Pipe Transducer Confi guration

Procedure

1) Establish communications with the transit time meter.

See Part 4 - Software Utility.

2) From the Tool Bar select Calibration. See Figure 2.7.

3) On the pop-up screen, click Next button twice to get to

Page 3 of 3. See Figure 2.8.

4) Click Edit.

5) If calibration point is displayed in Calibration Points Edi-

tor screen, record the information, highlight and click

Remove. See Figure 2.9.

6) Click ADD...

7) Enter Delta T, Un-calibrated Flow, and Calibrated Flow

values from the DTTS/DTTC calibration label, the click

OK. See Figure 2.10.

8) Click OK in the Edit Calibration Points screen.

9) Process will return to Page 3 of 3. Click Finish. See

Figure 2.8.

10) After “Writing Confi guration File” is complete, turn

power off . Turn on again to activate new settings.

UltraLINK Device Addr 127

Device Addr 127

Flow:

Totalizer Net:

Pos:

Neg:

Sig. Strength:

Margin:

Delta T:

Last Update:

Help

Window

Communications

View

Edit

File

Print Previe

1350 Gal/Min

0 OB

15.6%

100%

-2.50 ns

09:53:39

0 OB

0 OB

Errors

rro

!

Configuration

Calibration

Strategy

1600

2000

1200

Scale:

60 Min

Time:

200

U

U

FIGURE 2.7 - DATA DISPLAY SCREEN

Calibration (Page 3 of 3) - Linearization

Gal/M

Delta Time

1) Please establish a

reference flow rate.

1FPS / 0.3MPS Minimum.

2) Enter the reference flow

rate below. (Do not enter 0)

3) Wait for flow to stabilize.

4) Press the Set button.

Flow:

Set

Export...

Edit

28.2

FIGURE 2.8 - CALIBRATION PAGE 3 OF 3

Calibration Points Editor

Select point(s) to edit or remove:

Add...

Remove

Select All

Select All

Select None

Select None

Edit...

Cancel

OK

30.00 ns 2000.00 Gal/Min 1.000

30.00 ns 2000.00 Gal/Min 1.000

FIGURE 2.9 - CALIBRATION POINTS EDITOR