Part 3 - inputs/outputs, Top view of pipe – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 16

16

06-TTM-UM-00158 8/2012

calculated transducer spacing. See Figure 2.13. Using

fi rm hand pressure, slowly move the transducer both

towards and away from the upstream transducer while

observing signal strength. Clamp the transducer at the

position where the highest signal strength is observed.

Signal strength of between 5 and 98 is acceptable. The

factory default signal strength setting is 5, however

there are many application specifi c conditions that may

prevent the signal strength from attaining this level.

A minimum signal strength of 5 is acceptable as long as

this signal level is maintained under all fl ow conditions.

On certain pipes, a slight twist to the transducer may

cause signal strength to rise to acceptable levels.

8) Certain pipe and liquid characteristics may cause signal

strength to rise to greater than 98. The problem with

oper

ating a TFXL with very high signal strength is

that the signals may saturate the input amplifi ers

and cause erratic readings. Strategies for lowering

signal strength would be changing the transducer

mounting method to the next longest transmis-

sion path. For example, if there is excessive signal

strength and the transducers are mounted in a

Z-Mount, try changing to V-Mount or W-Mount.

Finally you can also move one transducer slightly

off line with the other transducer to lower signal

strength.

9)

Secure the transducer with a stainless steel strap

or other fastener.

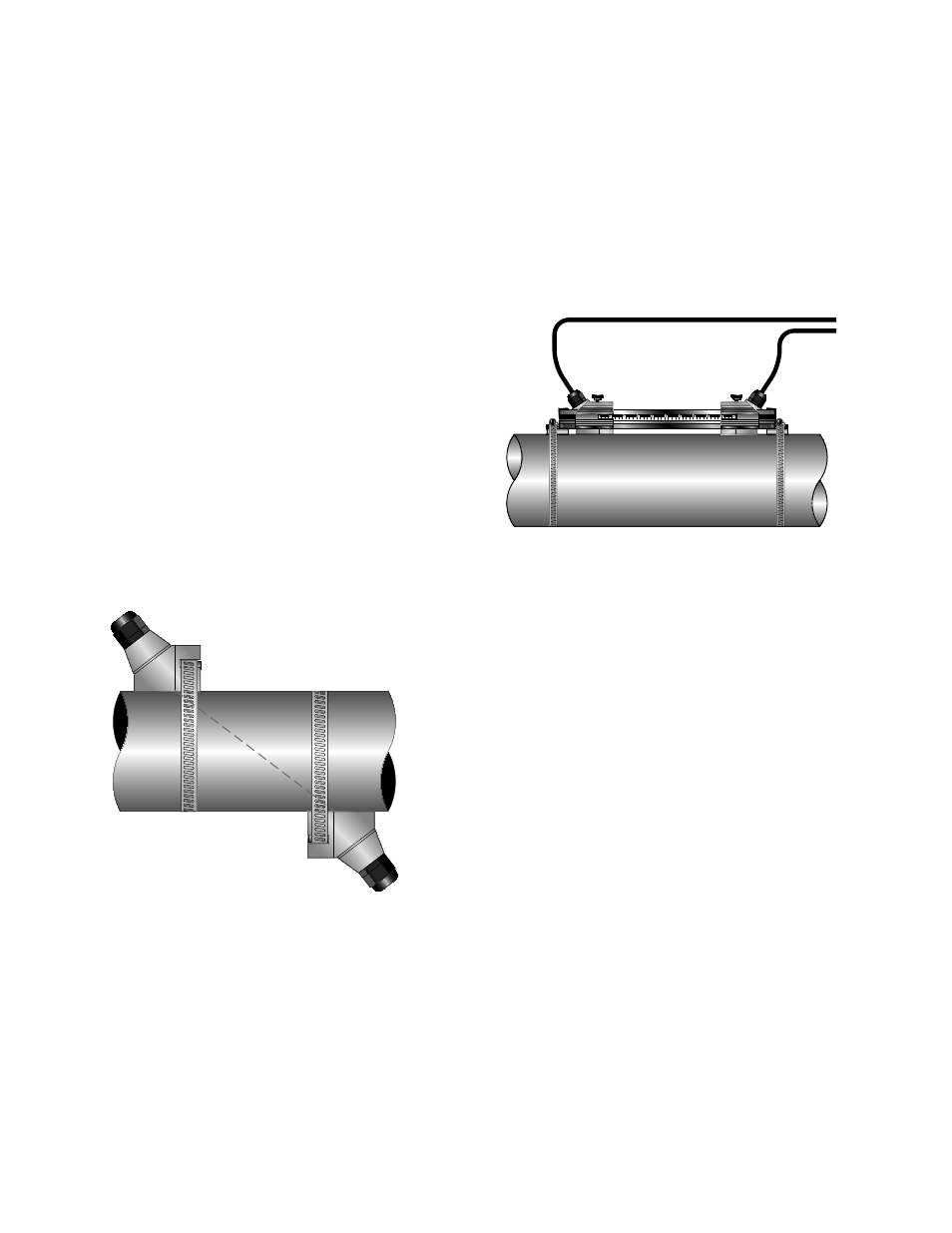

TOP VIEW

OF PIPE

FIGURE 2.13 - Z-MOUNT TRANSDUCER PLACEMENT

MOUNTING TRACK INSTALLATION

1) A convenient transducer mounting track can be used

for pipes that have outside diameters between 2 and

10 inches (50 and 250 mm). If the pipe is outside of that

range, select a V-Mount or Z-Mount mounting method.

2) Install the single mounting rail on the side of the pipe

with the stainless steel bands provided. Do not mount it

on the top or bottom of the pipe. Orientation on

vertical pipe is not critical. Ensure that the track is

parallel to the pipe and that all four mounting feet are

touching the pipe.

3) Slide the two transducer clamp brackets towards the

center mark on the mounting rail.

4) Place a single bead of couplant, approximately ½ inch

(12 mm) thick, on the fl at face of the transducer. See

Figure 2.4.

5) Place the fi rst transducer in between the mounting rails

near the zero point on the scale. Slide the clamp over

the transducer. Adjust the clamp/transducer such that

the notch in the clamp aligns with zero on the scale. See

Figure 2.14.

Top View

of Pipe

FIGURE 2.14 - MOUNTING TRACK INSTALLATION

6) Secure with the thumb screw. Ensure that the screw

rests in the counter bore on the top of the transducer.

(Excessive pressure is not required. Apply just enough

pressure so that the couplant fi lls the gap between the

pipe and transducer.)

7) Place the second transducer in between the mounting

rails near the dimension derived in the transducer

spacing section. Read the dimension on the mounting

rail scale. Slide the transducer clamp over the trans-

ducer and secure with the thumb screw.

PART 3 - INPUTS/OUTPUTS

GENERAL

The TFXL is available in two general confi gurations. There is

the standard TFXL fl ow model that is equipped with a 4-20

mA output and a rate frequency output.

The TFXL is also available with a totalizing pulse output.

4-20 mA OUTPUT

The 4-20 mA output interfaces with most recording and

logging systems by transmitting an analog current signal

that is proportional to system fl ow rate. The 4-20 mA output

is internally powered (current sourcing) and can span nega-

tive to positive fl ow/energy rates.