Alignment marks, Transducer positioning, 12 mm) – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 13: Figure 2.3 - transducer alignment marks, Figure 2.4 - application of couplant

06-TTM-UM-00158 8/2012

13

the transducers should be mounted 180 radial degrees from

one another and at least 45 degrees from the top-dead-

center and bottom-dead-center of the pipe. See Figure 2.2.

Also see

Z-Mount Transducer Installation

. On vertical pipes

the orientation is not critical.

45°

45°

YES

YES

45°

45°

FLOW METER

MOUNTING ORIENTATION

DTTS and DTTC TRANSDUCERS

TOP OF

PIPE

45°

45°

YES

YES

45°

45°

FLOW METER

MOUNTING ORIENTATION

DTTN and DTTH TRANSDUCERS

TOP OF

PIPE

45°

45°

YES

YES

45°

45°

FLOW METER

MOUNTING ORIENTATION

2” DTTS and DTTC TRANSDUCERS

TOP OF

PIPE

FIGURE 2.2 - TRANSDUCER ORIENTATION —

HORIZONTAL PIPES

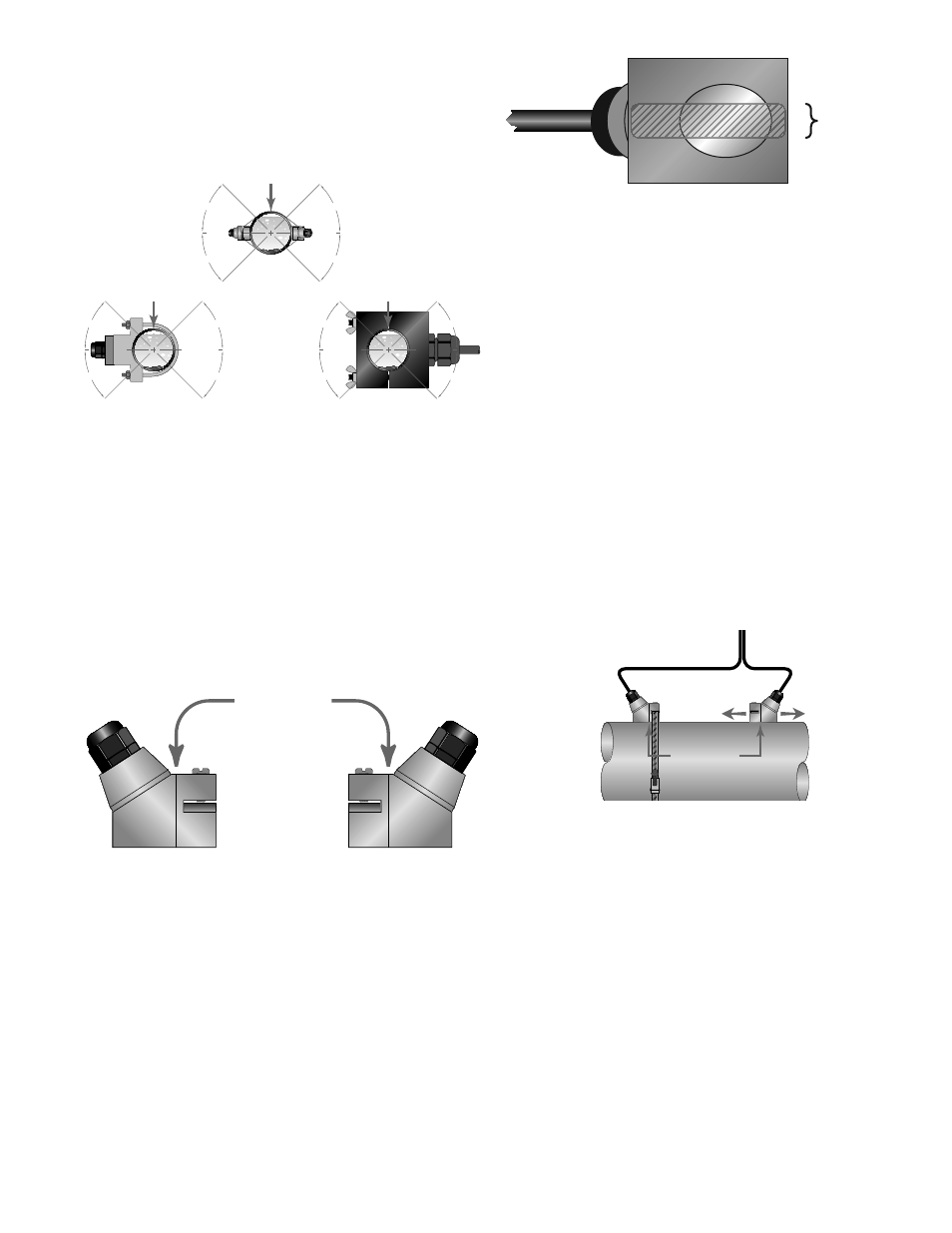

The spacing between the transducers is measured between

the two spacing marks on the sides of the transducers. These

marks are approximately 0.75” (19 mm) back from the nose of

the DTTN and DTTH transducers. See Figure 2.3.

DTTS and DTTC transducers should be mounted with the

cable exiting within ±45 degrees of the side of a horizontal

pipe. See Figure 2.2. On vertical pipes the orientation does

not apply.

Alignment

Marks

FIGURE 2.3 - TRANSDUCER ALIGNMENT MARKS

V-MOUNT AND W-MOUNT INSTALLATION

APPLICATION OF COUPLANT

For DTTN and DTTH transducers, place a single bead of

couplant, approximately ½ inch (12 mm) thick, on the fl at

face of the transducer. See Figure 2.4. Generally, a silicone-

based grease is used as an acoustic couplant, but any grease-

like substance that is rated not to “fl ow” at the temperature

that the pipe may operate at will be acceptable. For pipe

surface temperature over 150° F (65° C), acoustic couplant

(P.N. D002-2011-011) is recommended.

½”

(12 mm)

FIGURE 2.4 - APPLICATION OF COUPLANT

TRANSDUCER POSITIONING

1) Place the upstream transducer in position and secure

with a mounting strap. Straps should be placed in the

arched groove on the end of the transducer. A screw

is provided to help hold the transducer onto the strap.

Verify that the transducer is true to the pipe and adjust

as necessary. Tighten the transducer strap securely.

2) Place the downstream transducer on the pipe at the

calculated transducer spacing. See Figure 2.5. Apply

fi rm hand pressure. If signal strength is greater than

5, secure the transducer at this location. If the signal

strength is not 5 or greater, using fi rm hand pressure

slowly move the transducer both towards and away

from the upstream transducer while observing signal

strength.

NOTE: Signal strength readings update only every few

seconds, so it is advisable to move the transducer 1⁄8”, wait, see

if signal is increasing or decreasing and then repeat until the

highest level is achieved.

Transducer

Spacing

FIGURE 2.5 - TRANSDUCER POSITIONING

Signal strength is displayed on the main data screen in

the software utility. See Part 4 of this manual for details

regarding the software utility. Clamp the transducer

at the position where the highest signal strength is

observed. The factory default signal strength cutoff

setting is 5, however there are many application specifi c

conditions that may prevent the signal strength from

attaining this level. For the TFXL, signal levels much

less than 5 will probably not be acceptable for reliable

readings.

3) If after adjustment of the transducers the signal

strength does not rise to above 5, then an alternate

transducer mounting method should be selected. If the

mounting method was W-Mount, then re-confi gure the

transmitter for V-Mount, move the downstream trans-

ducer to the new spacing distance and repeat Step 4.