Mounting transducers in z-mount configuration – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 15

06-TTM-UM-00158 8/2012

15

Model: DTTSJP-050-N000-N

S/N: 39647

Delta-T: 391.53nS

Uncal. Flow: 81.682 GPM

Cal. Flow: 80 GPM

391.53

81.682

80.000

Delta T:

Uncalibrated Flow:

Calibrated Flow:

ns

Gal/Min.

Gal/Min.

Cancel

OK

Edit Calibration Points

FIGURE 2.10 - EDIT CALIBRATION POINTS

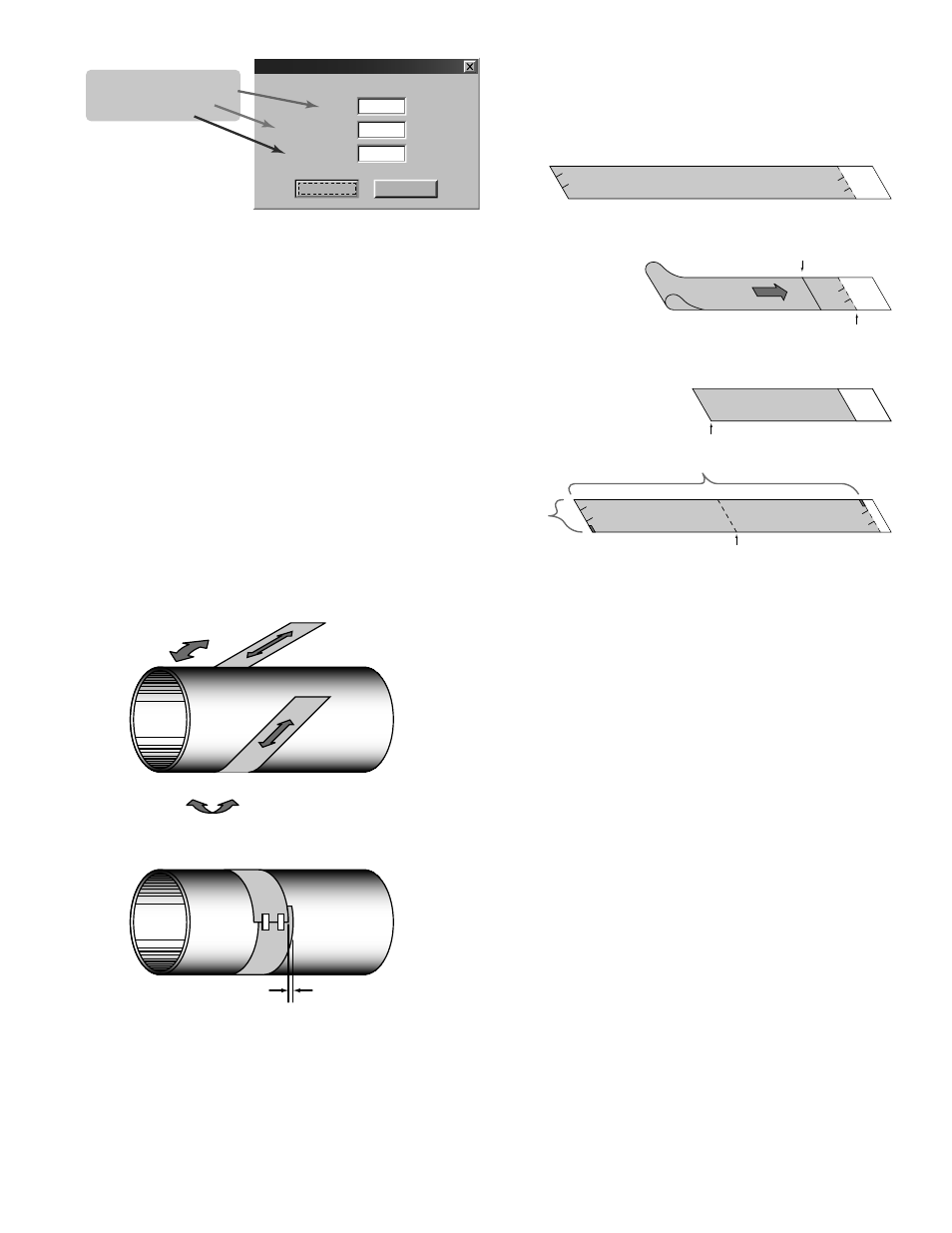

MOUNTING TRANSDUCERS IN Z-MOUNT

CONFIGURATION

Installation on larger pipes requires careful measurements

of the linear and radial placement of the DTTN and DTTH

transducers. Failure to properly orient and place the trans-

ducers on the pipe may lead to weak signal strength and/or

inaccurate readings. This section details a method for prop-

erly locating the transducers on larger pipes. This method

requires a roll of paper such as freezer paper or wrapping

paper, masking tape and a marking device.

1) Wrap the paper around the pipe in the manner shown

in Figure 2.11. Align the paper ends to within ¼ inch

(6 mm).

2) Mark the intersection of the two ends of the paper to

indicate the circumference. Remove the template and

spread it out on a fl at surface. Fold the template in half,

bisecting the circumference. See Figure 2.12.

LESS THAN ¼” (6 mm)

FIGURE 2.11 - PAPER TEMPLATE ALIGNMENT

3) Crease the paper at the fold line. Mark the crease. Place

a mark on the pipe where one of the transducers will

be located. See Figure 2.2 for acceptable radial orienta-

tions. Wrap the template back around the pipe, placing

the beginning of the paper and one corner in the loca-

tion of the mark. Move to the other side of the pipe and

mark the pipe at the ends of the crease. Measure from

the end of the crease (directly across the pipe from the

fi rst transducer location) the dimension derived in Step

2, Transducer Spacing. Mark this location on the pipe.

Line Marking

Circumference

Edge of

Paper

Fold

Pipe Circumference

Crease

(Center of Pipe)

Transducer

Spacing

FIGURE 2.12 - BISECTING THE PIPE CIRCUMFERENCE

4) The two marks on the pipe are now properly aligned

and measured. If access to the bottom of the pipe

prohibits the wrapping of the paper around the circum-

ference, cut a piece of paper ½ the circumference of the

pipe and lay it over the top of the pipe. The length of ½

the circumference can be found by:

½ Circumference = Pipe O.D. × 1.57

The transducer spacing is the same as found in the

Transducer Positioning section. Mark opposite corners

of the paper on the pipe. Apply transducers to these

two marks.

5) For DTTN and DTTH transducers, place a single bead of

couplant, approximately ½ inch (12 mm) thick, on the

fl at face of the transducer. See Figure 2.4. Generally, a

silicone-based grease is used as an acoustic couplant,

but any good quality grease-like substance that is rated

to not “fl ow” at the temperature that the pipe may

operate at will be acceptable.

6) Place the upstream transducer in position and secure

with a stainless steel strap or other fastening device.

Straps should be placed in the arched groove on the

end of the transducer. A screw is provided to help hold

the transducer onto the strap. Verify that the transducer

is true to the pipe, adjust as necessary. Tighten trans-

ducer strap securely. Larger pipes may require more

than one strap to reach the circumference of the pipe.

7) Place the downstream transducer on the pipe at the