Step 2 - transducer spacing – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 11

06-TTM-UM-00158 8/2012

11

*

**

Flow

*

**

Flow

*

**

Flow

*

**

Flow

Flow

*

**

Flow

*

**

24

24

14

10

10

10

5

5

5

5

5

5

*

**

Upstream

Pipe

Diameters

Downstream

Pipe

Diameters

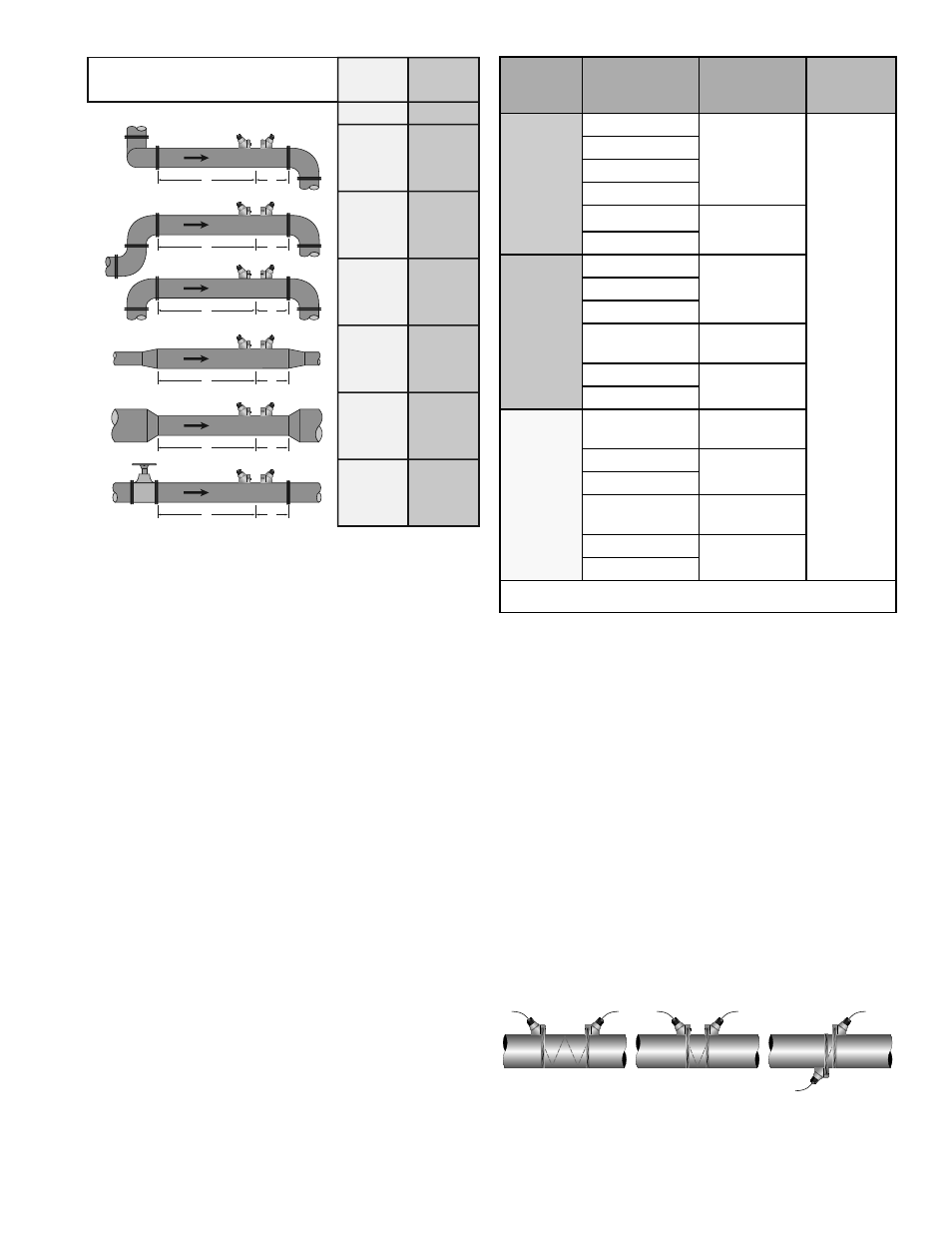

Piping Configuration

and Transducer Positioning

TABLE 2.1 - PIPING CONFIGURATION AND

TRANSDUCER POSITIONING

~ Mount the transducers in an area where they will not

be inadvertently bumped or disturbed during normal

operation.

~ Avoid installations on downward fl owing pipes unless

adequate downstream head pressure is present to over-

come partial fi lling of or cavitation in the pipe.

The fl ow meter system will provide repeatable measure-

ments on piping systems that do not meet these require-

ments, but accuracy of these readings may be infl uenced to

various degrees.

STEP 2 - TRANSDUCER SPACING

TFXL remote mount transit time fl ow meters can be used

with four diff erent transducer types: DTTN, DTTH, DTTS

and DTTC. Meters that utilize the DTTN or DTTH transducer

sets consist of two separate sensors that function as both

ultrasonic transmitters and receivers. DTTS and DTTC trans-

ducers integrate both the transmitter and receiver into one

assembly that fi xes the separation of the piezoelectric crys-

tals. DTTN and DTTH transducers are clamped on the outside

of a closed pipe at a specifi c distance from each other.

Transducer

Mount

Mode

Pipe Material

Pipe Size

Liquid

Composition

W-Mount

Plastic (all types)

2-4 in.

(50-100 mm)

Low TSS;

non-aerated

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Not

recommended

Cast Iron

V-Mount

Plastic (all types)

4-12 in.

(100-300 mm)

Carbon Steel

Stainless Steel

Copper

4-30 in.

(100-750 mm)

Ductile Iron

2-12 in.

(50-300 mm)

Cast Iron

Z-Mount

Plastic (all types)

> 30 in.

(> 750 mm)

Carbon Steel

> 12 in.

(> 300 mm)

Stainless Steel

Copper

> 30 in.

(> 750 mm)

Ductile Iron

> 12 in.

(> 300 mm)

Cast Iron

TSS = Total Suspended Solids

TABLE 2.2 - TRANSDUCER MOUNTING MODES

— DTTN AND DTTH

The DTTN and DTTH transducers can be mounted in:

W-Mount where the sound traverses the pipe four

times. This mounting method produces the best relative

travel time values but the weakest signal strength.

V-Mount where the sound traverses the pipe twice.

V-Mount is a compromise between travel time and

signal strength.

Z-Mount where the transducers are mounted on oppo-

site sides of the pipe and the sound crosses the pipe

once. Z-Mount will yield the best signal strength but

the smallest relative travel time.

For further details, reference Figure 2.1. The appropriate

mounting confi guration is based on pipe and liquid char-

acteristics. Selection of the proper transducer mounting

method is not entirely predictable and many times is an

TOP VIEW

OF PIPE

W-Mount

V-Mount

Z-Mount

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

FIGURE 2.1- TRANSDUCER MOUNTING MODES —

DTTN AND DTTH