Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 12

12

06-TTM-UM-00158 8/2012

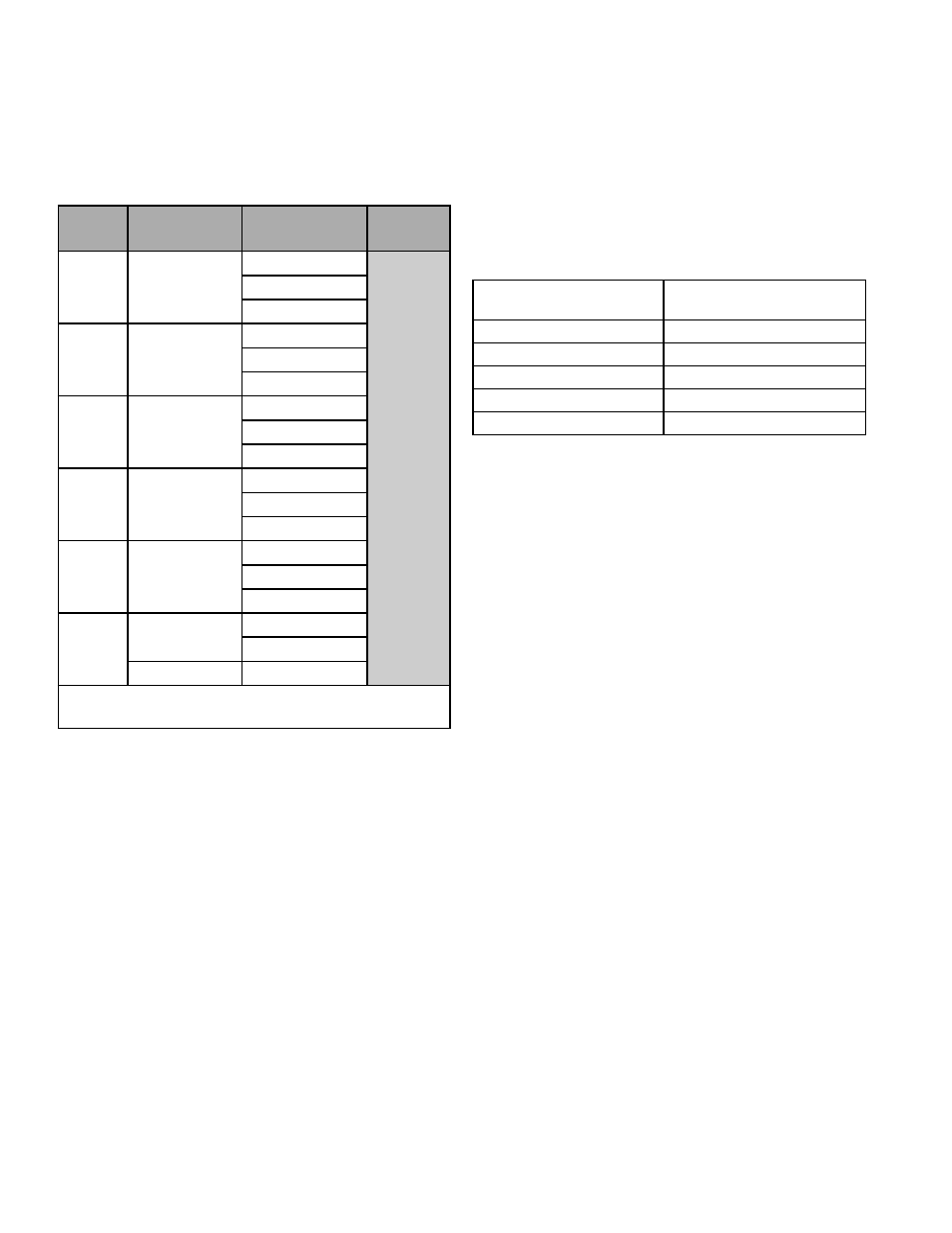

iterative process. Table 2.2 contains recommended mounting

confi gurations for common applications. These recom-

mended confi gurations may need to be modifi ed for specifi c

applications if such things as aeration, suspended solids, out

of round piping or poor piping conditions are present. Use of

the TFXL diagnostics in determining the optimum transducer

mounting is covered later in this section.

Size

Frequency

Setting

Transducer

Mounting

Mode

½

2 MHz

DTTSnP

V

DTTSnC

DTTSnT

¾

2 MHz

DTTSnP

DTTSnC

DTTSnT

1

2 MHz

DTTSnP

DTTSnC

DTTSnT

1¼

2 MHz

DTTSnP

DTTSnC

DTTSnT

1½

2 MHz

DTTSnP

DTTSnC

DTTSnT

2

1 MHz

DTTSnP

DTTSnC

2 MHz

DTTSnT

NOTE: DTTS transducer designation refers to both DTTS

and DTTC transducer types.

TABLE 2.3 - TRANSDUCER MOUNTING

MODES — DTTS / DTTC

STEP 3 - ENTERING PIPE AND LIQUID DATA

The TFXL system calculates proper transducer spacing by

utilizing piping and liquid information entered by the user.

This information can be entered on a TFXL via the software

utility.

The best accuracy is achieved when transducer spacing is

exactly what the TFXL calculates, so the calculated spacing

should be used if signal strength is satisfactory. If the pipe

is not round, the wall thickness not correct or the actual

liquid being measured has a diff erent sound speed than the

liquid programmed into the transmitter, the spacing can vary

from the calculated value. If that is the case, the transducers

should be placed at the highest signal level observed by

moving the transducers slowly around the mount area.

NOTE: Transducer spacing is calculated on “ideal” pipe.

Ideal pipe is almost never found so the transducer spacing

distances may need to be altered. An eff ective way to maxi-

mize signal strength is to confi gure the display to show signal

strength, fi x one transducer on the pipe and then starting

at the calculated spacing, move the remaining transducer

small distances forward and back to fi nd the maximum signal

strength point.

Important! Enter all of the data on this list, save the data and

reset the TFXL before mounting transducers.

The following information is required before programming

the instrument:

Transducer mounting

confi guration

Pipe O.D. (outside diameter)

Pipe wall thickness

Pipe material

Pipe sound speed

1

Pipe relative roughness

1

Pipe liner thickness (if present)

Pipe liner material (if present)

Fluid type

Fluid sound speed

1

Fluid viscosity

1

Fluid specifi c gravity

1

NOTE: Much of the data relating to material sound speed,

viscosity and specifi c gravity is pre-programmed into the TFXL

fl ow meter. This data only needs to be modifi ed if it is known

that a particular application’s data varies from the reference

values. Refer to Part 4 of this manual for instructions on

entering confi guration data into the TFXL fl ow meter via the

software.

1

NOMINAL VALUES FOR THESE PARAMETERS ARE INCLUDED

WITHIN THE TFXL OPERATING SYSTEM. THE NOMINAL

VALUES MAY BE USED AS THEY APPEAR OR MAY BE MODI-

FIED IF EXACT SYSTEM VALUES ARE KNOWN.

After entering the data listed above, the TFXL will calculate

proper transducer spacing for the particular data set. This

distance will be in inches if the TFXL is confi gured in English

units, or millimeters if confi gured in metric units.

STEP 4 - TRANSDUCER MOUNTING

PIPE PREPARATION

After selecting an optimal mounting location (Step 1) and

successfully determining the proper transducer spacing

(Step 2 & 3), the transducers may now be mounted onto the

pipe (Step 4).

Before the transducers are mounted onto the pipe surface,

an area slightly larger than the fl at surface of each transducer

must be cleaned of all rust, scale and moisture. For pipes with

rough surfaces, such as ductile iron pipe, it is recommended

that the pipe surface be wire brushed to a shiny fi nish. Paint

and other coatings, if not fl aked or bubbled, need not be

removed. Plastic pipes typically do not require surface prepa-

ration other than soap and water cleaning.

The DTTN and DTTH transducers must be properly oriented

and spaced on the pipe to provide optimum reliability and

performance. On horizontal pipes, when Z-Mount is required,