Basic tab general, Transducer, Figure 4.2 - data display screen – Dynasonics TFXL Clamp-On Ultrasonic Flow User Manual

Page 19: Configuration

06-TTM-UM-00158 8/2012

19

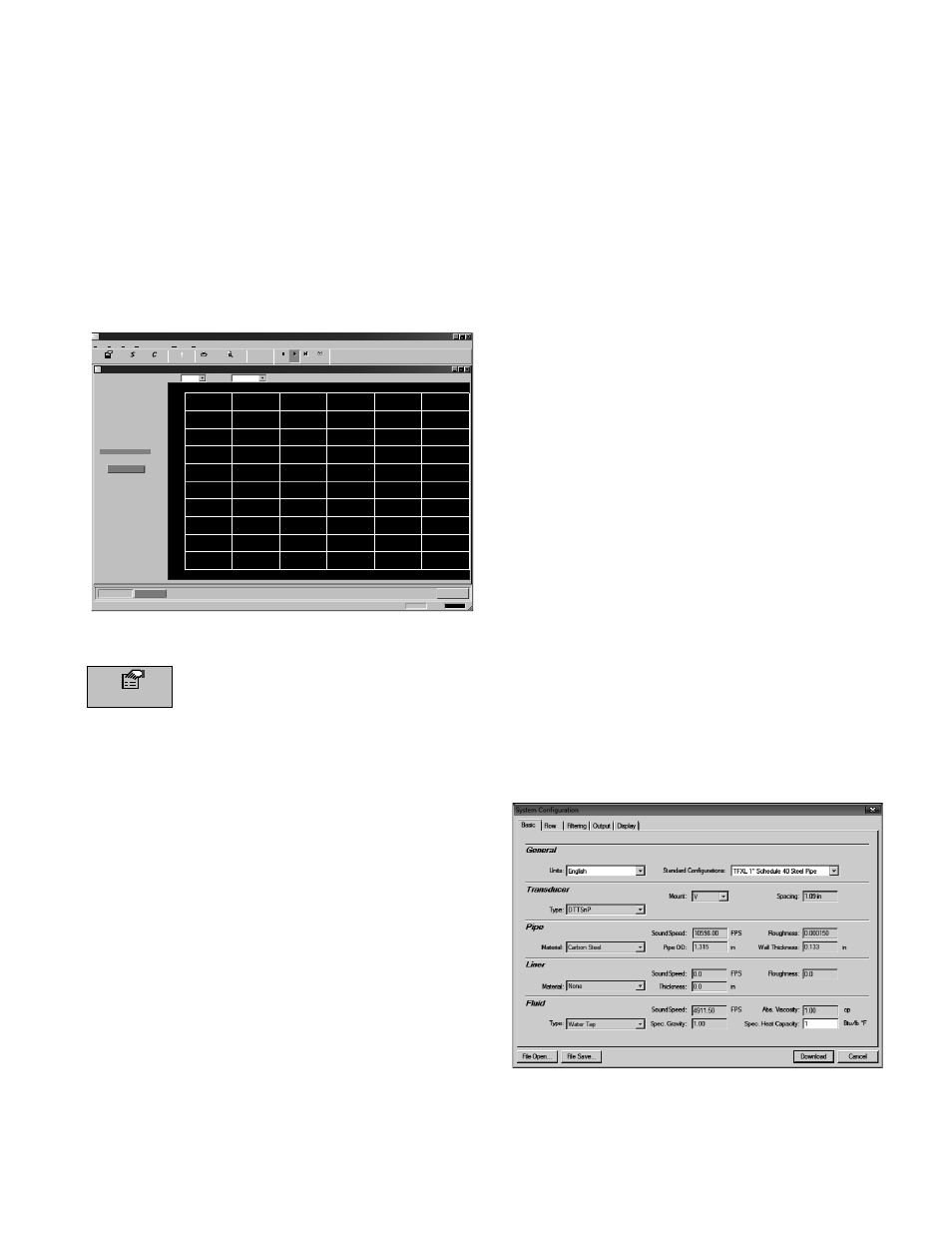

2) Double-click on the ULTRALINK icon. The fi rst screen is

the “RUN” mode screen (see Figure 4.2), which contains

real-time information regarding fl ow rate, totals, signal

strength, communications status, and the fl ow meter’s

serial number. The COMM indicator in the lower right-

hand corner indicates that the serial connection is

active. If the COMM box contains a red ERROR, click

on the Communications button on the Menu bar and

select Initialize. Choose the appropriate COM port and

the RS232 / USB Com Port Type. Proper communica-

tion is verifi ed when a green OK is indicated in the

lower right-hand corner of the PC display and the “Last

Update” indicator in the text area on the left side of the

screen changes from red to an active clock indication.

UltraLINK Device Addr 127

Data Display

Diagnostics

Device Addr 127

Reset Totalizers

Help

Window

Communications

View

Edit

File

About

?

?

Errors

rro

!

Configuration

Calibration

Strategy

Exit

OK

13:26:33 COMM:

For Help, press F1

Go

Stop

Stop

Stop

Step

View

-1.00:00

-2000

-1600

1600

-1200

-800

-400

2000

1200

800

400

0

-50:00

-40:00

-30:00

-20:00

-10:00

-0:00

Time (mm:ss)

Flow Rate

Historical Data

Scale:

Time:

60 Min

2000

135 Gal/Min

237 Gal

15.6%

100%

2.50 ns

Flow:

Totalizer Net:

Pos:

Neg:

Sig. Strength:

Margin:

Delta T:

Last Update: 12:17:20

0 Gal

237 Gal

Print Preview

U

U

Signal Strength too Low!

FIGURE 4.2 - DATA DISPLAY SCREEN

Configuration

The Confi guration drop-down houses six

screens used to control how the TFXL is set up

and responds to varying fl ow conditions. The

fi rst screen that appears after clicking the Confi guration

button is the Basic screen. See Figure 4.3.

BASIC TAB

GENERAL

The general heading allows users to select the measurement

system for meter setup, either English or Metric and choose

from a number of pre-programmed small pipe confi gura-

tions in the Standard Confi gurations drop-down. If pipe

measurements are to be entered in inches, select English. If

pipe measurements are to be entered in millimeters, select

Metric. If the General entries are altered from those at instru-

ment start-up, then click on the Download button in the

lower right-hand portion of the screen and cycle power to

the TFXL.

When using the Standard Confi gurations drop-down menu

alternate, menu choices can be made by using the following

guidelines:

1) Select the transducer type and pipe size for the trans-

ducer to be used. The fi rmware will automatically enter

the appropriate values for that pipe size and type. Every

entry parameter except for Units, Standard Confi gura-

tions, and Specifi c Heat Capacity will be unavailable

behind a “grayed out” entry box.

2) Go back to the Standard Confi gurations drop-down

menu and select Custom. As soon as Custom is chosen,

the previously grayed out selections will become avail-

able for editing.

3) Make any changes to the Basic confi guration deemed

necessary and press Download.

4) To ensure that the confi guration changes take eff ect,

turn the power off and then back on again to the

transmitter.

TRANSDUCER

Transducer Type selects the transducer that will be

connected to the TFXL fl ow meter. Select the appropriate

transducer type from the drop-down list. This selection

infl uences transducer spacing and fl ow meter performance,

so it must be correct. If you are unsure about the type of

transducer to which the TFXL will be connected, consult the

shipment packing list or call the manufacturer for assistance.

NOTE: A change of Transducer Type will cause a System

Confi guration Error (1002: Sys Confi g Changed) to occur. This

error will clear when the microprocessor is reset or power is

cycled on the fl ow meter.

Transducer Mount selects the orientation of the transducers

on the piping system. See Part 2 of this manual and Table

2.2 for detailed information regarding transducer mounting

modes for particular pipe and liquid characteristics. When-

ever Transducer Mount is changed, a download command

and subsequent microprocessor reset or fl ow meter power

cycle must be conducted.

FIGURE 4.3 - BASIC TAB