Datamax-O'Neil M-Class Mark II Operator’s Manual User Manual

Page 57

Chapter 5 – Maintenance and Adjustments

51

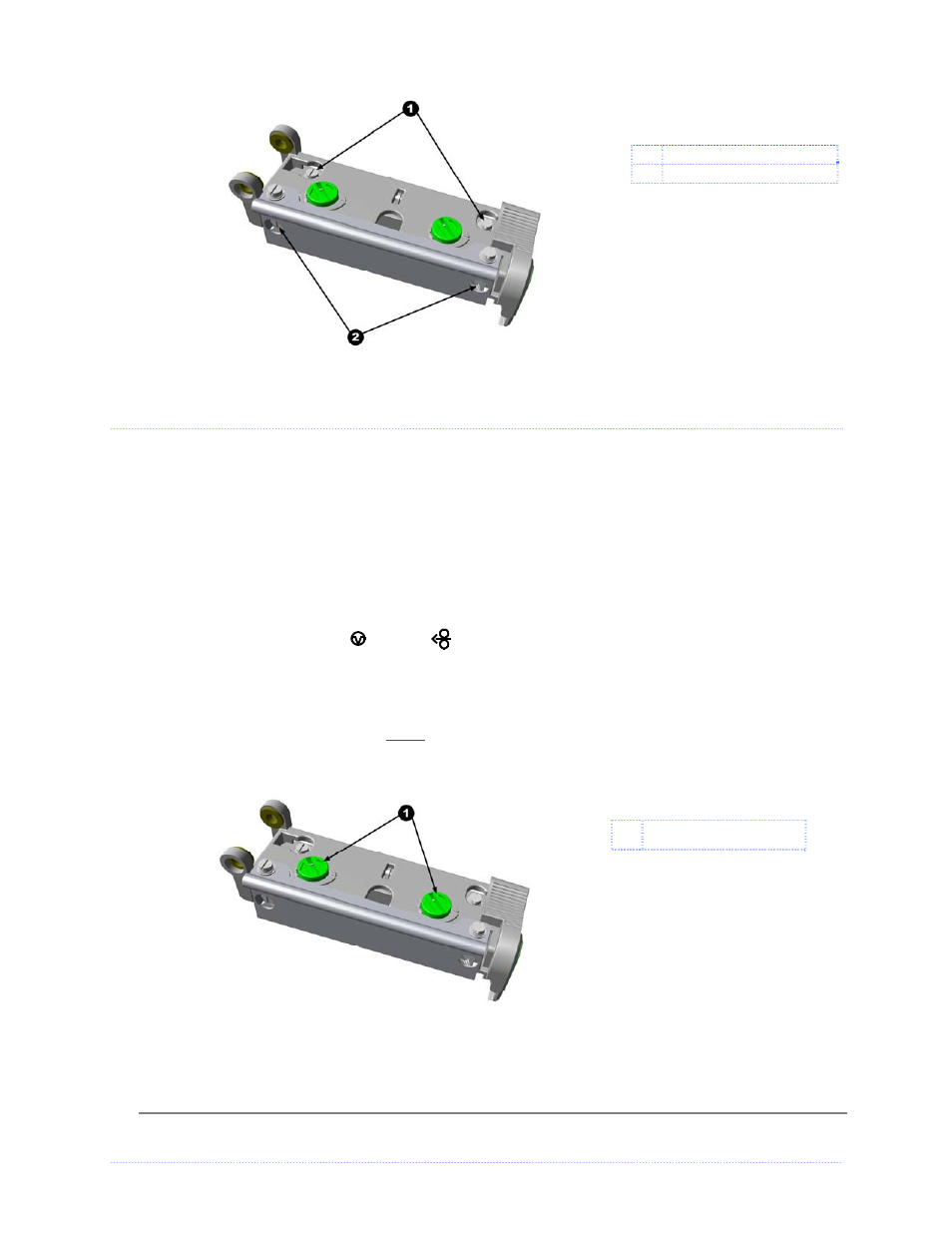

Locking Screws

Adjustment Screws

5

5

5

.

.

.

5

5

5

P

P

P

r

r

r

i

i

i

n

n

n

t

t

t

h

h

h

e

e

e

a

a

a

d

d

d

P

P

P

r

r

r

e

e

e

s

s

s

s

s

s

u

u

u

r

r

r

e

e

e

A

A

A

d

d

d

j

j

j

u

u

u

s

s

s

t

t

t

m

m

m

e

e

e

n

n

n

t

t

t

To accommodate a variety of media types, printhead pressure is adjustable. This pressure is

factory set to work with most media types, so this adjustment should only be performed after

attempting to improve print quality through the use of the (1) heat and/or (2) print speed. When

adjusting, use only the minimum pressure necessary for better imaging. To adjust:

1. Load at least 4” (102mm) wide media and ribbon, see Section 2.2.

2. Ensure the Media Width Adjustment is set to its “left most” position, see Section 5.3.

3. Print a test label.

Non-display printers:

Simultaneously press the

PAUSE

+

FEED

buttons

Display-equipped printers:

See Section 4.4

4. Turn the Pressure Adjustment Cams counterclockwise to increase the applied pressure or

clockwise to decrease it. Make equal adjustments to each cam to achieve even print contrast

across the media.

Pressure Adjustment

Cams

When using narrow media it is sometimes necessary to increase the pressure on the inner

(closest to centerplate) Pressure Adjustment Cam to prevent ribbon smudging.

Excessive pressure can reduce the service life of the printhead and platen roller, while unequal

pressure may cause ribbon and label tracking problems.