Head pressure control valve operation ori/ord – ClimaCool IOM AR2 SERIES User Manual

Page 56

54

www.climacoolcorp.com

®

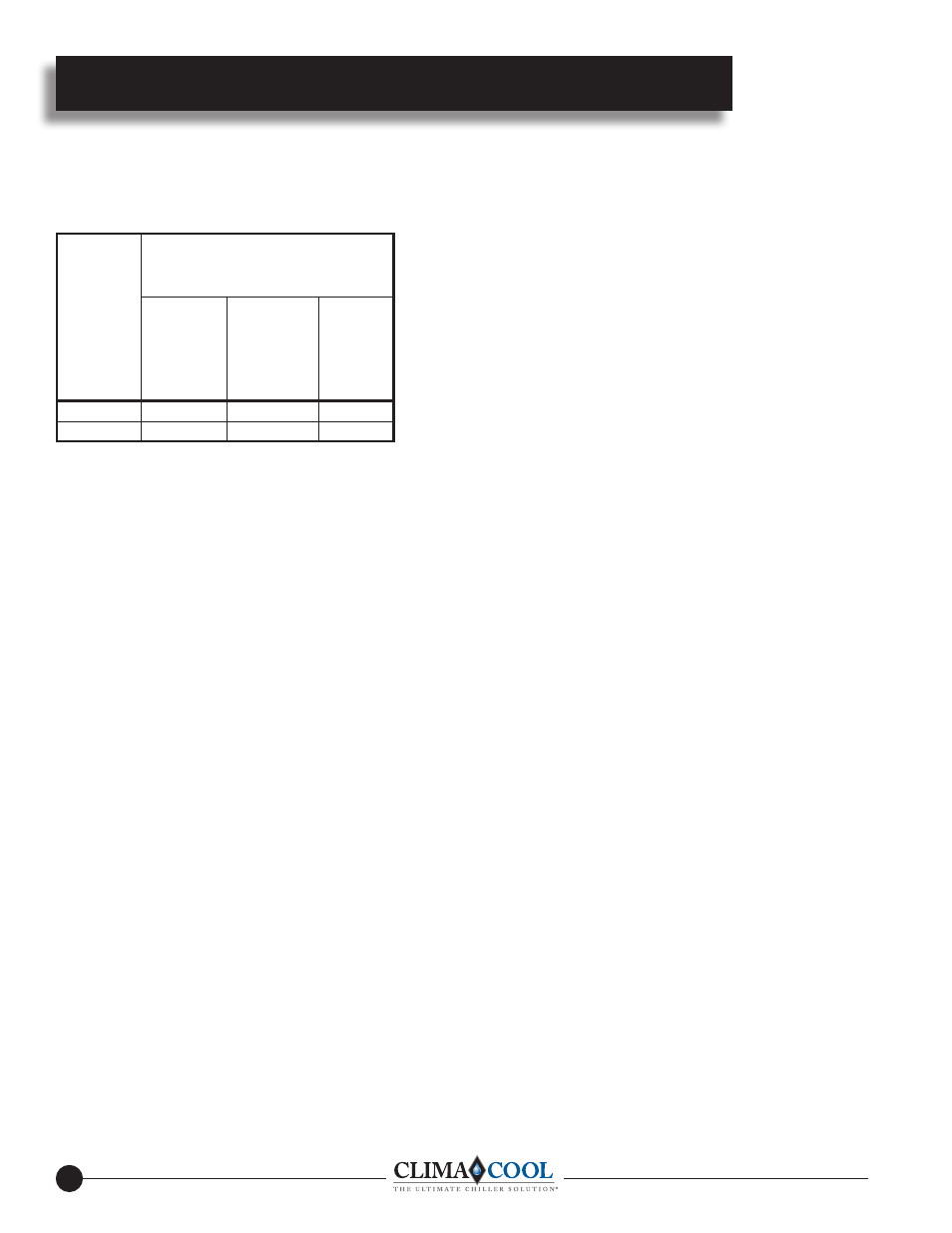

The table below lists the setting data for the ORI and ORD valves .

Other ORI settings can be obtained by adjusting the valves a

proportionate amount between those values shown .

The ORD-4-20 setting means that the ORD-4 will start to open when

the pressure difference between the discharge line and the receiver is

20 psig . This setting is suitable for all systems where the combined

pressure drop through the condenser, the ORI and connecting piping

is less than 14 psi . Therefore, if the ORI is selected for 2 psi P,

then the maximum allowable pressure drop through the condenser is

12 psi . Normally, condenser pressure drop on refrigeration systems

is less than 10 psi . However, many condensers on air conditioning

systems may have pressure drops up to 25 psi . Therefore, when

in doubt, consult with the equipment manufacturer or, if possible,

measure it by reading the discharge pressure at the compressor and

the receiver pressure during full load operation . That is, this reading

should be taken with a normal condensing temperature at full load .

For systems where the condenser pressure drop is higher than normal,

ORD valves with higher settings are available upon special request .

To adjust the ORI valve, remove the cap and turn the adjustment

screw with the proper size hex wrench (1/4” for ORI-6 and 5/16”

for ORI- 10) . A clockwise rotation increases the valve setting while

a counter-clockwise rotation decreases the setting . To obtain the

desired setting, a pressure gauge should be utilized at the compressor

discharge service valve so the effects of any adjustment can be

observed . Small adjustments are recommended to allow the system

adequate time to settle out after each adjustment . NOTE: Even though

the ORI valve is selected on the basis of the full load conditions

or summer operation, it should be adjusted to maintain the desired

condensing pressure whenever the ambient is below 70°F .

DETERMINING AMOUNT OF CHARGE — When “refrigerant

side” head pressure control is utilized on a system, one of the most

important factors is determining the total system refrigerant charge .

While on most packaged units the amount of charge is listed on the

unit, the required charge for a field built-up system cannot be listed by

the manufacturer . Charge is usually added when the system is started

up until “proper” system performance is reached . However, this is not

satisfactory and if the system is to function properly year-round, the

correct amount of extra charge must be calculated ahead of time .

1 — COMPLETELY FLOODED CONDENSER: The easiest

method is to calculate the volume of the condenser coil and then use

the density factor of the refrigerant shown in Table-1 to figure the

pounds of refrigerant necessary to completely flood the condenser

coil at the appropriate ambient . The factors involved in calculating the

extra pounds of refrigerant are:

a . Length of tubing and return bends in condenser

b . Minimum ambient temperature at which systems will be required

to function

c . Tubing size and wall thickness

d . Refrigerant

The primary point to remember in selecting the proper density factor

is that when the liquid drain valve (ORI) is throttling, the refrigerant

temperature will be at the same temperature as the ambient .

Example: Calculate the extra refrigerant charge necessary for a

Refrigerant 22, roof-top, air conditioning unit (40°F evaporator

and a minimum condensing temperature of 90°F) with compressor

unloading to 50% of full compressor capacity . To determine the

equivalent length of tubing in a condenser, proceed as follows: First,

count the number of tubes and multiply this by their length .

Example: 150 tubes x 7.55 feet = 1132.5 feet

Next, count the return bends and multiply them by the factor shown

in Table-1 .

Example: 150 bends x .250 for 1/2 inch bends = 37.5 feet Then

add this 37.5 feet to the 1132.5 feet for a total of 1170 feet

The system uses a 30 hp condensing unit with a condenser coil

containing 1170 equivalent feet of 1/2 inch tubing tubes and return

bends) . Assume a design temperature of minus 20°F minimum

ambient . From Table-1 we find the density factor necessary to

calculate the pounds of extra refrigerant to completely flood the

condenser at minus 20°F: 1170 feet x .102 pounds/foot = 119 pounds .

2 — PARTIALLY FLOODED CONDENSER:

On many systems it isn’t necessary to completely flood the condenser to

maintain sufficient operating head pressure (equivalent to approximately

90°F condensing temperature) because of a milder climate than Method

1 assumes . Therefore, a second method is available . The additional

information found in Tables 2 and 3 can be used to figure more closely

the charge necessary to properly flood the condenser for sufficient head

pressure at various minimum ambient temperatures . (The multipliers are

applied to the extra refrigerant charge that was calculated in Method 1 to

completely flood the condenser .)

Head Pressure Control Valve Operation ORI/ORD

Settings for Refrigerants

R-22 and R-407C

Valve

Type

Pressure

Setting

PSIG

Depth of

adjusting

nut from

top of

Spring

Housing

Turns

IN

from

Factory

Setting

ORI-10

200

¾”

5

ORD-4-20

20

—

—