Head pressure control valve operation ori/ord – ClimaCool IOM AR2 SERIES User Manual

Page 54

52

www.climacoolcorp.com

®

Head Pressure Control Valve Operation ORI/ORD

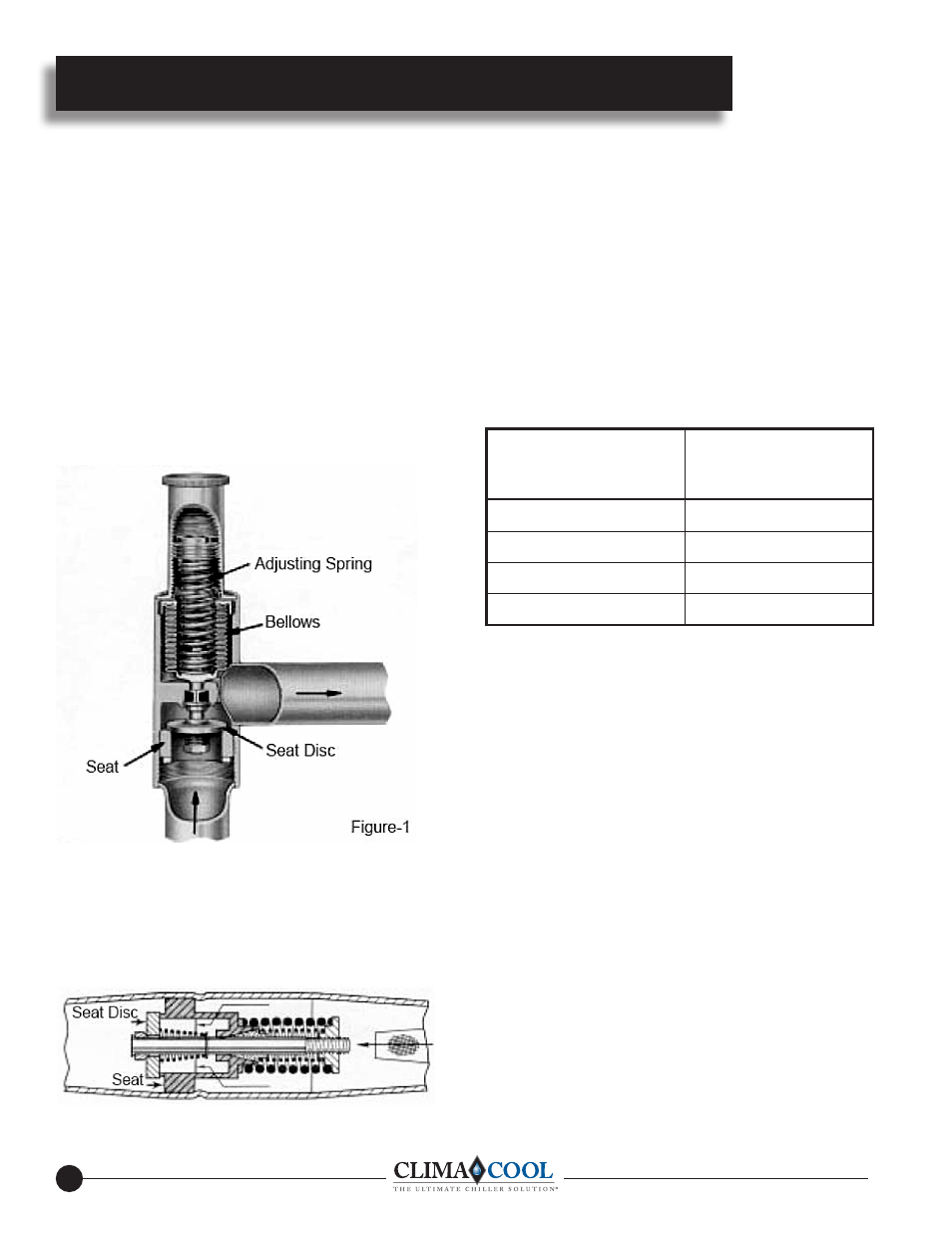

ORI VALVE OPERATION — The ORI head pressure control

valve is an inlet pressure regulating valve and responds to changes

in condensing pressure only . The valve designation stands for Opens

on Rise of Inlet pressure . As shown in Figure-1, the outlet pressure

is exerted on the underside of the bellows and on top of the seat disc .

Since the effective area of the bellows is equal to the area of the port,

the outlet pressure cancels out and the inlet pressure acting on the

bottom of the seat disc opposes the adjusting spring force . These

two forces are the operating forces of the ORI . When the outdoor

ambient temperature changes, the ORI opens or closes in response

to the change in condensing pressure . An increase in inlet pressure

above the valve setting tends to open the valve . And if the ambient

temperature drops, the condenser capacity is increased and the

condensing pressure drops off . This causes the ORI to start to close or

assume a throttling position .

ORD VALVE OPERATION— The ORD valve is a pressure

differential valve that responds to changes in the pressure difference

across the valve, Figure-3 . The valve designation stands for Opens

on Rise of Differential pressure . Therefore, the ORD is dependent

on some other control valve or action for its operation . And in this

respect, it is used with the ORI for head pressure control .

As the ORI valve starts to throttle the flow of liquid refrigerant from

the condenser, a pressure differential is created across the ORD .

When the differential reaches 20 psi, the ORD starts to open and

bypasses hot gas to the liquid drain line . As the differential increases,

the ORD opens further until its full stroke is reached at a differential

of 30 psi . Due to its function in the control of head pressure, the full

stroke can be utilized in selecting the ORD . While the capacity of the

ORD increases as the pressure differential increases, the rating point

at 30 psi is considered a satisfactory maximum value . The standard

pressure setting for the ORD is 20 psig . For systems where the

pressure drop between the compressor and the receiver is higher than

14 psi, an ORD with a higher setting is available . See Table

ADJUSTABLE ORI/ORD SYSTEM OPERATION — The

adjustable ORI head pressure control valve and the nonadjustable

ORD pressure differential valve comprise an improved system

of head pressure control . For years the usual system utilized two

adjustable or one adjustable valve with a check valve and an elevation

requirement for “refrigerant side” head pressure control . With the

introduction of the ORD-4 pressure differential valve in January 1968,

not only was the system simplified due to a one valve adjustment and

the ability to locate the condenser and receiver on the same elevation,

but the ORI/ORD system was more economical to buy . The operation

of the ORI/ORD system is such that a constant receiver pressure is

maintained for normal system operation . Since the ORI is adjustable

over a nominal range of 65 to 225 psig, the desired pressure can be

maintained for all of the commonly used Refrigerants 12, 22, and

502 . As shown in Figure-4, the ORI is located in the liquid drain line

between the condenser and the receiver . And the ORD is located in a

hot gas line bypassing the condenser . During periods of low ambient

temperature, the condensing pressure falls until it approaches the

setting of the ORI valve . The ORI then throttles, restricting the flow

of liquid from the condenser . This causes refrigerant to back up in the

condenser thus reducing the active condenser surface . This raises the

condensing pressure . Since it is really receiver pressure that needs to

be maintained, the bypass line with the ORD is required .

Maximum Pressure

Drop Between

Compressor and

Receiver (PSI)

Head Pressure

Component Selection

Below

14

ORD-20 & ORI

15 to

19

ORD-25 & ORI

20 to

24

ORD-30 & ORI

25 to

29

ORD-35 & ORI