Application parameters – ClimaCool IOM AR2 SERIES User Manual

Page 42

40

www.climacoolcorp.com

®

THE CLIMACOOL MODULAR CHILLER -

APPLICATION PARAMETERS

Remote Condenser Control Panels Factory assembled fan cycling

control panels are available to cycle fans for head pressure

control either on ambient temperature or condensing pressure .

Contact ClimaCool for Custom applications for fan speed control

or custom built control panels .

• All fans are cycled with contactors .

• Condensers with a single row cycle fans separately with one

contactor per fan (e .g . Model #RC1-08A) .

• Condensers with two rows of fans will have each row of fans

dedicated to one specific refrigeration circuit . Since the fans

closest to the header end of the unit run continuously, the

second fan in each row will cycle independently to control

head pressure corresponding to the circuit it serves .

• Standard control circuit voltage is 24 volts . Optional Control

circuit voltages of 230 or 115 volts are available on request .

• Standard control circuits require an external power supply for

powering control circuit (by others) .

• Optional factory mounted control circuit transformer is

available on 460 volt condenser fan motor voltage to provide

power to the control circuit

Head Pressure Control by Ambient Fan Cycling

Condenser fans are controlled by ambient temperature using

electronic temperature controls . Ambient fan cycling is

recommended for multi-circuited condensers or single circuit

condensers where there is little variation in condenser load, such

as the condenser model # RC1-08A, which is a single row of

fans to serve one of the refrigeration circuits of a 30-ton module,

model AR2-30 .

Ambient fan cycling is limited in its ability to control head

pressure to mild ambient conditions, see Table 2 for minimum

recommended ambient temperatures for fan cycling . By request,

ClimaCool can provide year round head pressure control by

combining ambient fan cycling with other such methods as

flooded head pressure control, or variable speed fans . Combining

flooded controls with ambient fan cycling also provides the

advantage of reducing the refrigerant required to flood the

condenser . Refer to Table 3 for typical settings for ambient

thermostats .

Application Parameters

Head Pressure Control by Ambient Fan Cycling

The most common method for controlling head pressure is to

cycle the condenser fans using high pressure control switches

sensing condenser pressure . Again, the fans closest to the header

end of the unit run continuously, thus second fan in each row will

cycle independently to control head pressure corresponding to the

refrigerant circuit it serves . As with ambient fan cycling, it is also

possible to combine alternate methods of head pressure control

with fan cycling by head pressure . Contact the factory for more

precise regulation of head pressure as required .

2

1

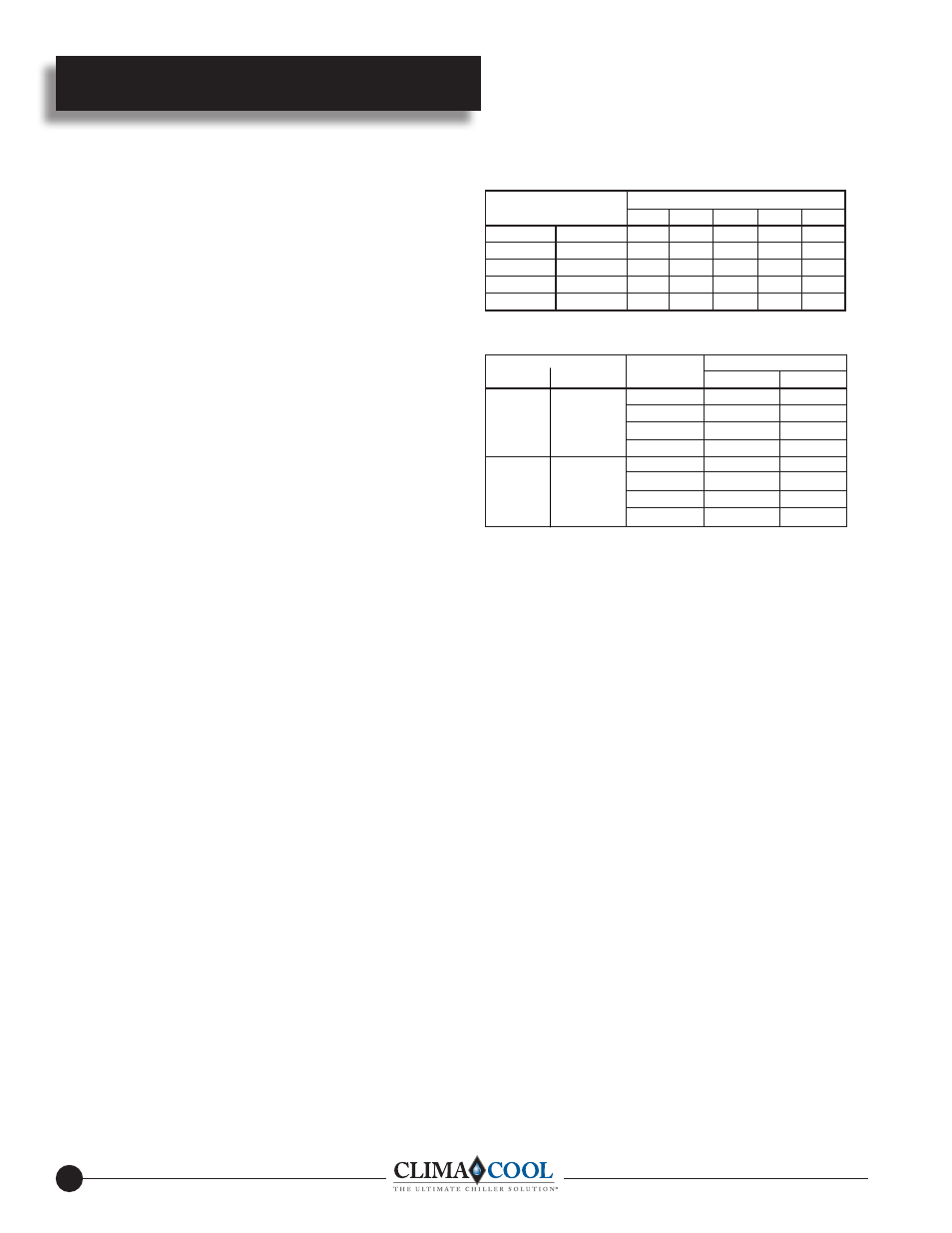

Table 2 - Minimum Ambient for Fan Cycling.

Desi n T.D.*

Number of Fans

Single Row Double

Row 30

25

20

15

10

2

4

35

45

55

60

70

3

6

15

30

40

55

65

4

8

0

15

30

45

60

5

10

0

10

20

35

55

6

12

0

0

10

30

50

Table 3 - Ambient Fan Cycling Thermostat Settings

Design

Thermostat Settin

Number of Fans

Single Bow Double Row

T.D.

2

4

30

60

25

65

20

70

15

75

3

6

30

60

40

25

65

55

20

70

60

15

75

65