Liquid line drier core replacement – ClimaCool IOM AR2 SERIES User Manual

Page 49

47

www.climacoolcorp.com

®

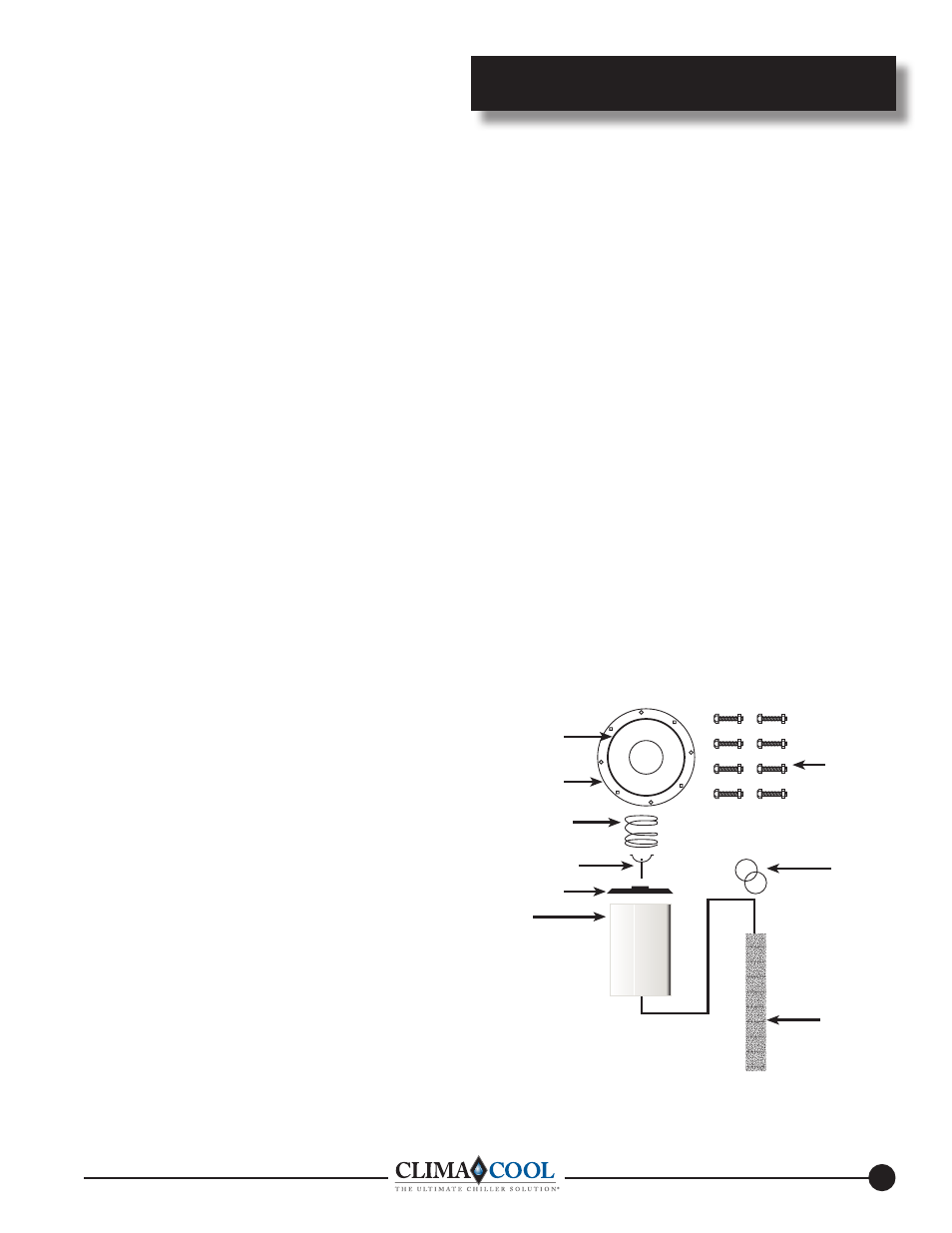

LIQUID LINE DRIER- INSTALLATION AND

REPLACEMENT INSTRUCTIONS

Replace any lost or damaged bolt and/or nut from a replaceable

core Catch-All Filter-Drier . All bolts and nuts torqued to the

proper value are required for proper safe fastening of the end

plate and to prevent leakage . Bolts should be torqued to 14 to

16 ft-lbs on the C-480 Series Catch-Alls . The cores used in

replaceable core Catch-All Filter-Driers are shipped in METAL

CANS HERMETICALLY SEALED to protect them from

contamination by moisture and dirt . The detailed instructions

for assembly and changing cores are given on these cans . The

following condensed instructions may be used if these cans are

not available .

1 . Always pump out the section of the line containing the filter-

drier by closing the hand valve located just before the drier

in the direction of refrigerant flow, and allow the compressor

to operate . After isolated section has been pumped out, close

the liquid line valve just after the filter drier, shut down the

chiller electrically and then change the core . Disposal of the

cores should be handled according to local laws . WARNING!

Dangerous hydraulic pressures may develop if hand valves

are closed and the filter-drier is full of liquid . When liquid

is trapped in a section of line, even a slight increase in

temperature results in a great increase in internal pressure .

2 . Make sure all the refrigerant is pumped out of the Catch-All

shell . The appropriate shut-off valves should be tightly closed .

3 . Remove the end plate and internal assembly, and clean the

internal parts . Remove the activated core from the sealed can .

The metal pull tab and pull strip permit the can to be opened

with the key or a pair of pliers . Do not replace the end plate

gasket unless it is damaged . When replacement is necessary,

select the outer gasket from the set supplied with each core .

Do not cut or abrade the gaskets used in the end plate .

4 . Remove the end spring, wing screw, and inlet plate from

outlet plate assembly . After the replacement core is slid onto

the outlet plate assembly with the proper o-rings, position

inlet plate on the end of the tubular screen . Fasten finger

tight the wing screw to assembly . The screw, when properly

fastened, tightens the components in the assembly thereby

prohibiting component movement and dirt bypassing around

the cores . Assemble the end spring on to the wing screw . The

design of the screw holds the spring in position so that the

end plate can be easily installed (especially when the shell is

mounted horizontally) . The end spring is designed to fit into

the circular groove on the end plate .

5 . Insert the assembly in the shell, replace the flange bolts,

tighten evenly to the recommended torque value (14 to 16 ft-

lbs for the C-R480 Series) .

CAUTION- The edge of the shell fits into the gasket groove

on the end plate and makes a seal against the gasket to prevent

refrigerant leakage . Be careful not to scratch or damage the edge

of the shell when changing the cores . If the edge of the shell

should become damaged, replace the shell to prevent possible

refrigerant leakage .

WHEN TO CHANGE CORES — Cores should be changed when

they become contaminated, or on a regular maintenance schedule .

Disposal of the cores should be handled according to local laws .

Cores that become contaminated with solid particles should be

changed whenever the pressure drop increases to the point where

it reduces system performance . When moisture is the major

concern, change the drier cores according to the indication of

the liquid line sight glass . The cores will remove their maximum

amount of moisture and come to equilibrium in approximately

one day of operation . When either acid or wax is the major

contaminant involved, the cores should be left in the system at

least three days to come to equilibrium thereby removing the

maximum amount of contaminants . Many users of replaceable

core Catch-Alls will change the cores every Spring and Fall as

part of their normal maintenance schedule .

Sporlan Drier Core Model #RCW-48- This drier core is designed

specially for use with POE oils, and is a high water capacity core .

Order this core as separate item . This core should be used on all

ClimaCool AR2 series chillers .

End Plate

Gasket

End Plate

(”-G” Feature Shown)

End Spring

Wing Screw

Inlet Plate

Core

Flange Bolts

and Nuts

O-Rings

Outlet Plate

Assembly

Outlet

Retainer

Plate Gasket

Shell

Liquid Line Drier Core Replacement