Setup and operation, A fast six-step process – Climax BB4500 LINE BORING MACHINE User Manual

Page 9

SeTup and operaTion

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone:

1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 9

SeTup and operaTion

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone:

1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 9

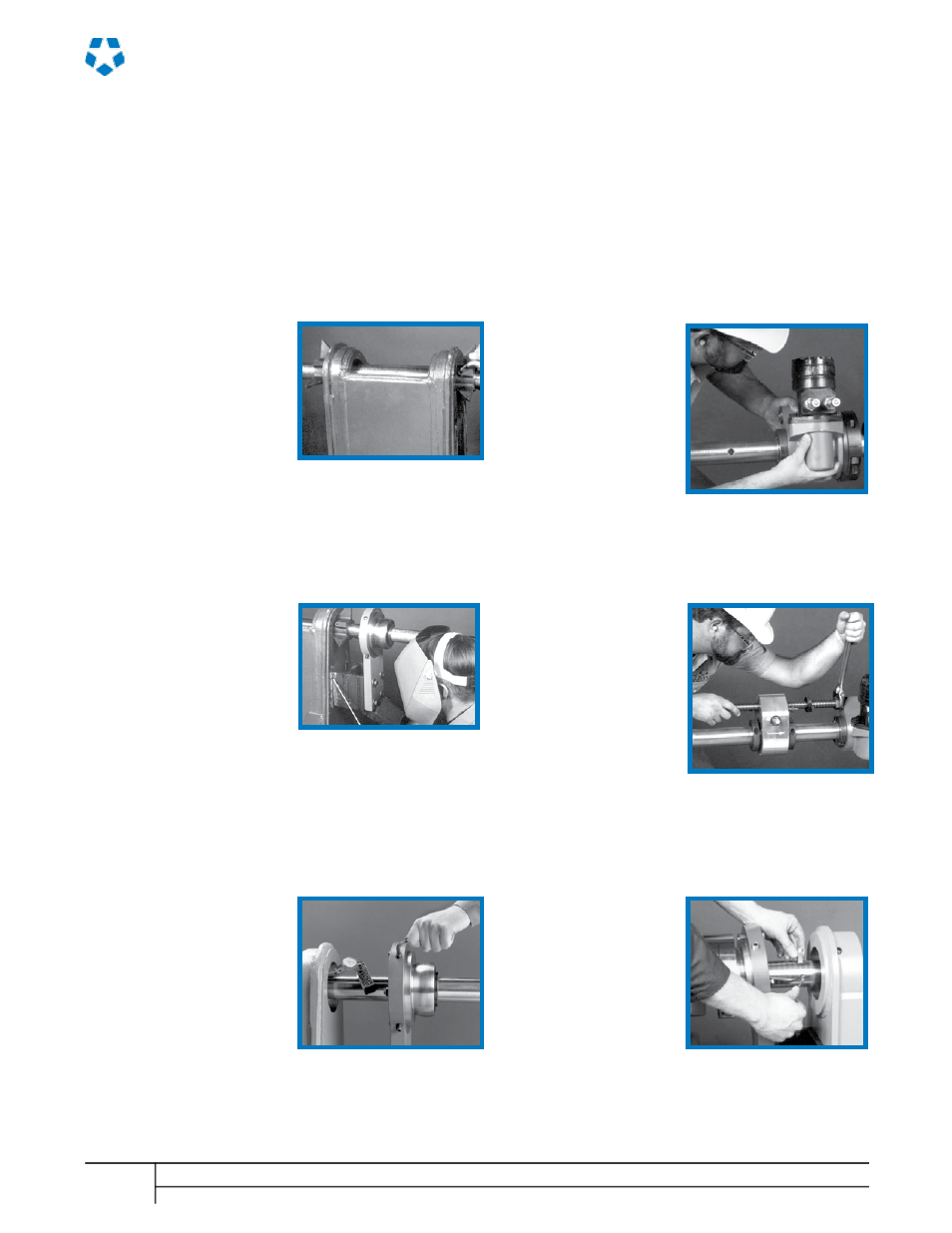

a fast Six-Step process

1

Slide the bar through the

two holes to be bored and

roughly center it with the

set-up cones. The set-up

cones are forced into the

bore with the clamp ring

jacking screw and locked

onto the bar with a set

screw.

Elapsed time: 4 minutes.

2

Slide on spherical mounts

with tack weld plates, and

tack weld them to the

workpiece.

These mounts have

spherical bearings so they

can be mounted up to

5° out of perpendicular

alignment.

Elapsed time: 10 minutes.

3

Remove the set-up

cones and replace the

bar. The set-up cones

will adequately center

the bar, unless you have

very precise tolerances,

or need to move the

center line of the bore

slightly. Final centering

adjustments are made

with the jacking screws.

Elapsed time: 5 minutes.

4

Slide the rotational drive

onto the bar until the self-

aligning mounting collar

is firmly seated on the

mounting bracket, and

lock it in place with one

screw.

Elapsed time: 2 minutes.

5

The axial feed unit is

slipped onto the bar and

the feedscrew is screwed

into the pocket on the

rotational drive unit.

Tightening two clamping

collars locks the axial

feed unit to the bar.

Elapsed time: 2 minutes.

6

Insert a properly ground

tool bit into the tool hole

in the bar, adjust for

depth of cut, and lock in

pla

ce with the set screw.

Elapsed time: 4 minutes.

Setup is complete, you

are ready to begin the

first pass.

Total elapsed time: 27

minutes.

Setup of the BB4500 Portable Boring Machine is quick and

easy. An experienced operator can set up the machine in most

typical two-bore line boring applications in about half an hour

(depending on alignment tolerances).

The three main ingredients of the quick setup system are:

• Setup cones to roughly center the bar in the bore.

• Spherical mounts that can be quickly tack-welded in place.

• Quick-mount rotational drive unit, attaches to spherical mount in

seconds