Specifications, Set-up – Climax PL4000 LATHE User Manual

Page 2

US

Metric

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 2

sPecifications

All dimensions should be considered reference. Contact your Climax Representative for precision dimensions. Specifications are subject to change without notice. There are no systems or components

on this machine that are capable of producing hazardous EMC, UV or other radiation hazards. The machine does not use lasers nor does it create hazardous materials such as gasses or dust.

Shaft diameter

Min.

8.0 inches

203.2 mm

Max. with standard tool holder

18.0 inches

457.2 mm

Max. with optional extender

24.0 inches

609.6 mm

Cutting reach

Min. with standard tool holder

0 inches

0 mm

Max. with standard tool holder

24.75 inches

628.7 mm

Min. with optional extender

3.25 inches

82.6 mm

Max. with optional extender

27.0 inches

685.8 mm

Max taper

2.5 inches/foot on diameter

63.5 mm/304.8 mm on diameter

(on 8 - 18 inch diameters)

(on 203.2 - 457.2 mm diameters)

Vertical tool travel, total

1.5 inches

38.1 mm

Tool feed, reversible

0 - 0.020 inches/rev

0 - 0.5 mm/rev.

Max. torque at tool head

450 ft-lb

610.1 N·m

Air motor

Rotational speed at max. rated Hp

520 rpm

520 rpm

Rotational speed at no-load

1100 rpm

1100 rpm

Air consumption at max. rated Hp

90 psi at 48 ft

3

/min

620 kPa at 136 cm

3

/min

Machine rotational speed

at max. rated Hp

21 rpm

21 rpm

at no-load

30 rpm

30 rpm

Cutter, square lathe tool bit

1

/

2

inch

12.7

mm

Operating weight

413 lbs

187.3 kg

Shipping weight

550 lbs

249.5 kg

Shipping dimensions

53 X 38 X 19 inches

1346.2 x 965.2 x 482.6 mm

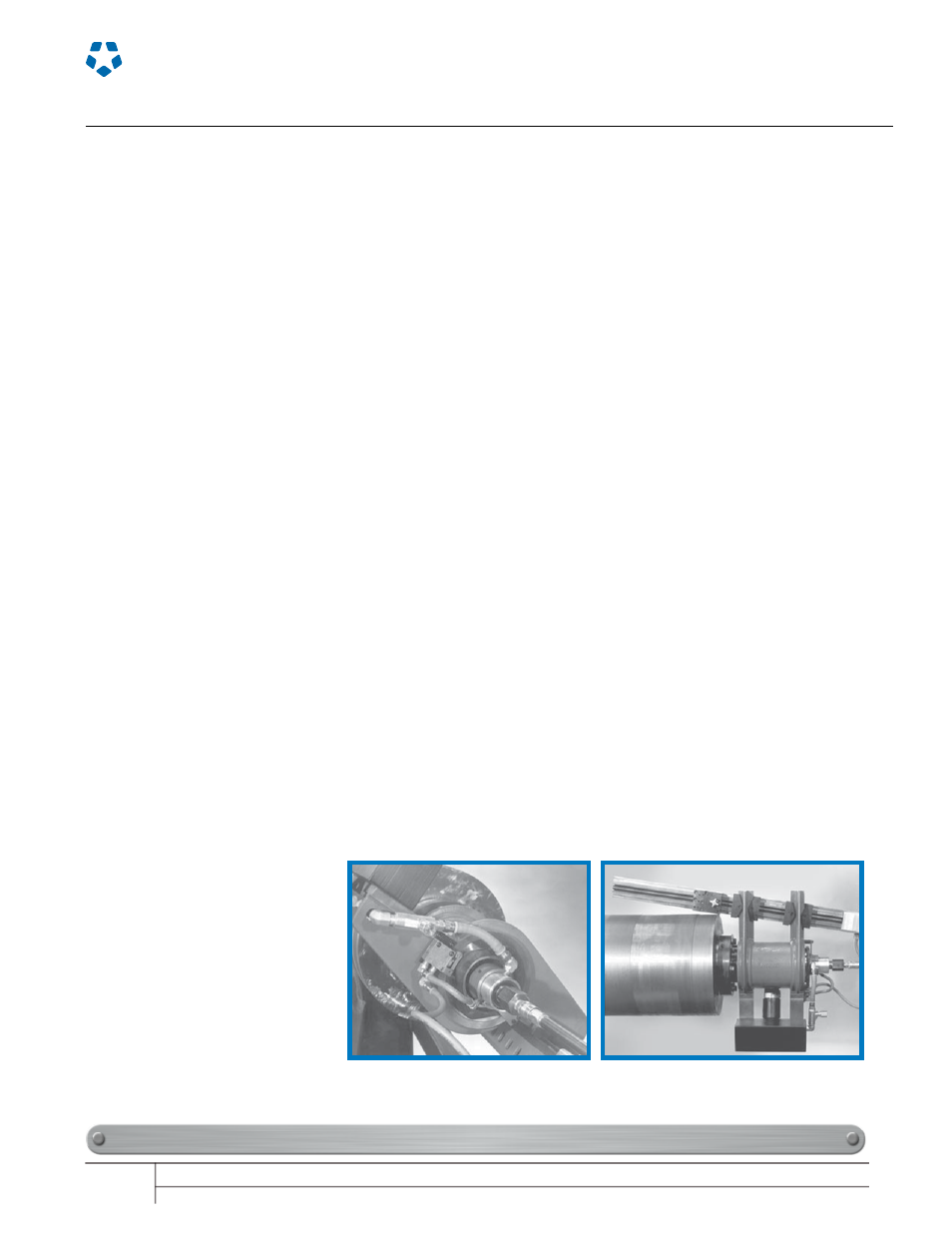

The Portable Lathe mounts to the shaft via

a mounting plate which is drilled and coun-

terbored to match the shaft. The lathe spin-

dle then mounts to the plate on four studs.

The turning bar mounts to arms on the

main body and can be easily adjusted for

reach and turning radius.

Parallelism between the bar and the

spindle is set by adjusting two tool arm

anchors until they measure

equidistant from measuring flats on the

main body. Parallelism with the work piece

is set using jacking screws. Set screws

provide centering.

Typical set-up time is 30 minutes (once the

mounting plate is prepared).

A simple cam and valve arrangement activates the

pneumatic tool feed mechanism.

The turning bar may be set at an angle for

cutting tapers up to 2.5 inches/foot (63.5 mm/304.8

mm) on diameter.

set-uP