Bray 98 Series User Manual

Page 37

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 37

Series 98 Operation & Maintenance

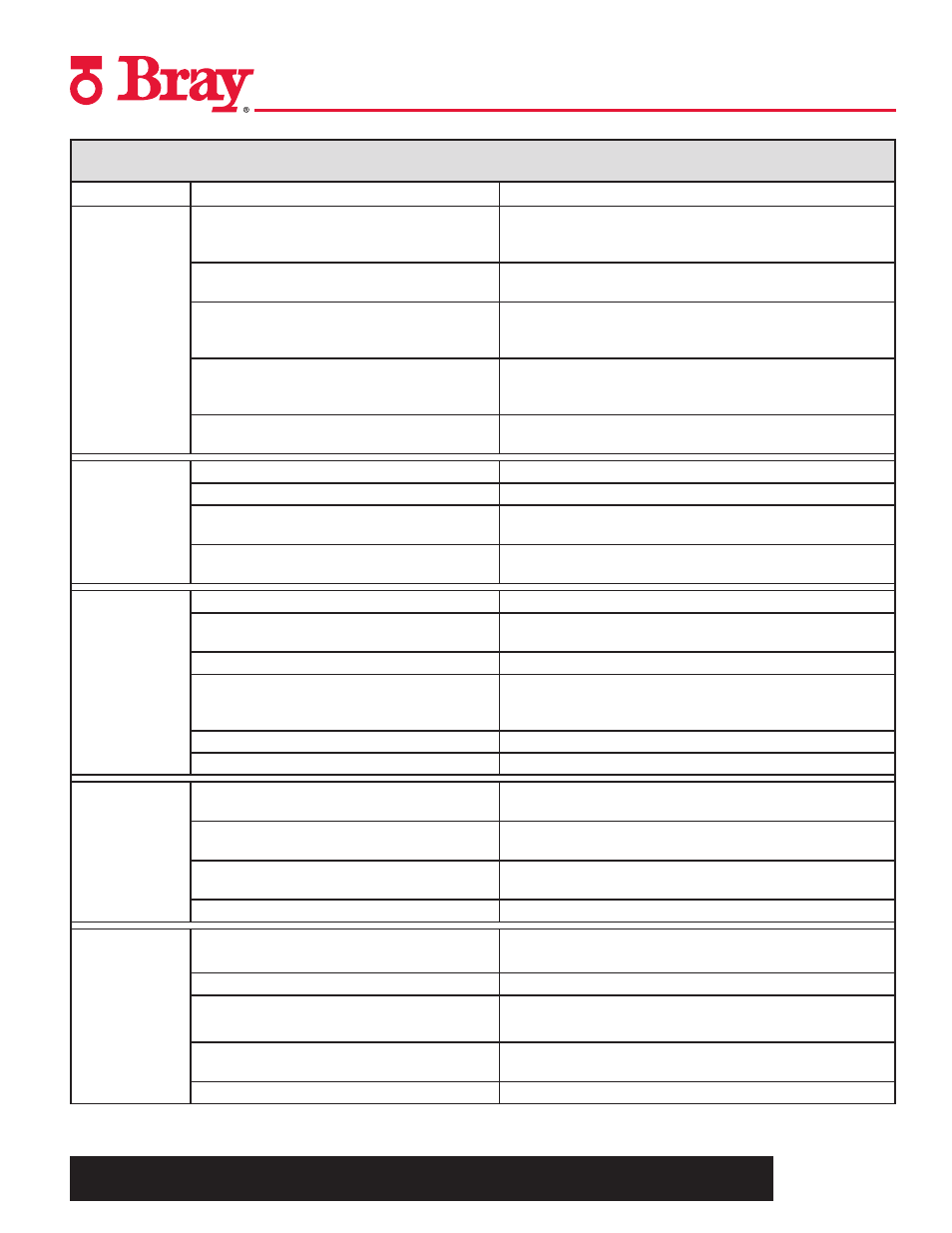

Trouble shooting potential problems

FAULT

POSSIBLE CAUSES

RECOMMENDED ACTIONS

Erratic Movement Inconsistent supply /dirty operating media/

clogged filters

Check media supply pressure and line filters, correct as

necessary. Refer to Introduction section in this manual for

operating media requirements.

Inadequate Lubrication

Disassemble and lubricate. Refer to Maintenance section in this

manual for lubricant specs.

Worn /damaged Parts

Disassemble and inspect. Replace worn/damaged parts. Refer

to Disassembly, Service & Reassembly of Modules section in this

manual.

Seal set due to long periods of inactivity

Operate for 5-10 cycles and check. Replace seals if not resolved.

Refer to the procedures under Pressure Module section in this

manual, for replacement and testing procedures.

Valve problem- bearing/seal friction, damaged

parts

Refer to valve manufacturer’s IOM.

Incomplete Stroke Stoppers set incorrectly

Check and adjust.

Foreign object left inside during maintenance

Disassemble, inspect for damages and correct.

Manual override in wrong position

Check and fully retract manual override devices for proper

automatic operation.

Valve problem- Restriction, friction,incorrect

valve stopper

Refer to valve manufacturer’s IOM .

Loss of power

Supply pressure inadequate

Check and correct supply pressure to operating pressure.

Inadequate flow

Check flow control devices and adjust for suffiecient flow.

Repair any kinked tubing.

Tubing or exhaust vents blocked

Check and clean the vents ,silencers and tubing

Pressure Module seals leaking

Check leaks and replace seals.Refer to the procedures under

Pressure Module section in this manual, for replacement and

testing procedures.

Defective Accessories/Inadequate capacity

Refer to accessory manufacturer’s OM manual and specs.

Valve jammed or requires higher torque

Refer to valve manufacturer’s IOM.

No response to

energizing

Altered schematic

Check if the control circuit is as per the supplied schematic.

Correct the circuit, if altered.

Solenoid valve /positioner/control elements mal-

function

Check /Refer to accessory manufacturer’s OM manual for

troubleshooting.

Disengaged piston rod/ broken connection/

jammed mechanism

Refer to Maintenance section for module/actuator disassembly

procedures to disassemble appropriate module for inspection.

Valve problem- jammed

Refer to valve manufacturer’s IOM.

Fails to go to the

failsafe position

Altered schematics

Check if the control circuit is as per the supplied schematic.

Correct the circuit, if altered.

Control component malfunction/failure

Check and replace

Choked exhaust silencer/foreign object blocking

exhaust line

Remove vent to confirm normal operation. Clean/replace

exhaust silencer

Spring rod disengaged/connection broken.

Refer to Maintenance section for module/actuator disassembly

procecures to disassemble appropriate module for inspection

Valve problem- jammed

Refer to valve manufacturer’s IOM.