Series 98 operation & maintenance, 1 operation – da hydraulic override, Caution – Bray 98 Series User Manual

Page 29: 2 disassembly of hydraulic cylinder, 3 servicing hydraulic cylinder

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 29

Series 98 Operation & Maintenance

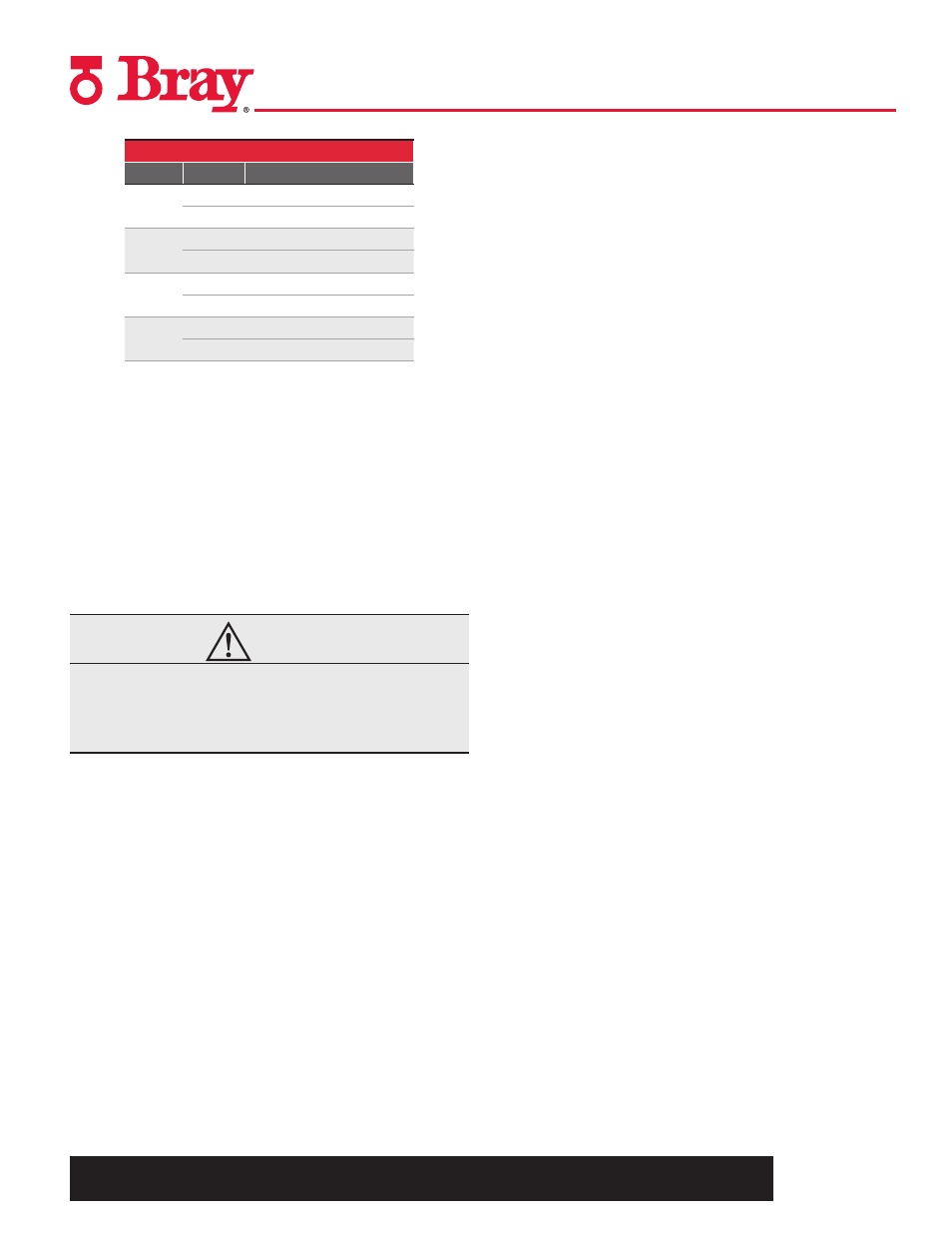

MOP for DA Hydraulic Overrides

Model

MOP

73 E2

psi

1930

bar

133

14 E3

psi

1970

bar

136

24 E3

psi

2080

bar

143

45 E3

psi

1965

bar

135

15.2.1 Operation – DA Hydraulic Override

1. For Manual Override operation, turn the 3-way valves on the

pressure module to vent the cylinder ports to atmosphere

and Close the hydraulic bypass valve, (HBV). Turn the lever

on the direction control valve on the hand pump unit to

select the direction of the actuator rotation and stroke the

hydraulic pump.

2. To restore Automatic operation, turn the direction control

valve to center position, the HBV to Open position and

switch the vent valves to connect the cylinder ports to the

air supply lines.

CAUTION

Over thrust by the hydraulic override may cause actuator

damage. Prevent unsafe conditions and damage by adjusting

the overload valve on the pump to limit the hydraulic pressure

as per the MOP tables.

15.3 Maintenance of Hydraulic Override

15.3.1 Spring Return Hydraulic Override Cylinder

Leakage of hydraulic fluid past the piston seal can be a cause for

failure to hold the position when operating the override. Leakage

can be confirmed if oil can be seen dripping out of the weep hole

on the cylinder. To correct this problem the cylinder must be

taken off the spring module.

15.3.2 Disassembly of Hydraulic Cylinder

1. Disconnect the air pressure and the electrical power from

the actuator and ensure the actuator turns to the fail safe

position.

2. Disconnect the hydraulic tubing from the override cylinder

port.

3. Remove the nuts and spring washers from the studs (10)

holding the cylinder flange on the Spring Module end.

4. Pull the cylinder out of the Spring Module and inspect for

leakage from the weep hole near the guide nut at the rod

end. Proceed to replace seals if leakage is confirmed or as

part of preventive maintenance.

5. Secure the cylinder, loosen and remove the rod end guide nut.

6. Pull the piston assembly out of the cylinder.

15.3.3 Servicing Hydraulic Cylinder

1. Remove the old seal from the piston and replace it with a new

U-cup seal. Install the face of the seal on the hydraulic pressure

side.

2. Replace the wear ring on the piston with a new one. Lubricate

the seal and the wear ring with hydraulic fluid and carefully

slide the piston into the cylinder.

3. Replace the o-ring and guide on the rod side nut and install

the nut.

4. Reassemble the cylinder on the Spring module, connect the

tubing and vent out the air from the line, as described in the

Installation Section.

5. Operate the hydraulic override to test for correct operation.

15.4 DA Override Cylinder

15.4.1 Disassembly of Hydraulic Cylinder

1. Operate the actuator so that the hydraulic cylinder piston is

at the cap end side.

2. Shift the direction control valve on the hand pump unit to

mid position, disconnect the air pressure and the electrical

power from actuator and ensure it stays in this position.

3. Disconnect the hydraulic tubing from the cylinder ports.

4. Remove the tie rod nuts off the hydraulic cylinder and pull

the end cap off the barrel.

5. With a socket spanner located on the hex head of the

hydraulic cylinder’s piston, loosen and disengage the piston

rod from the Guide Block in the Torque Module.

6. Remove the fasteners holding the hydraulic cylinder’s flange

on the Torque Module end.

7. Take the cylinder assembly off the Torque Module.