0 jackscrew override, Series 98 operation & maintenance – Bray 98 Series User Manual

Page 31

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 31

Series 98 Operation & Maintenance

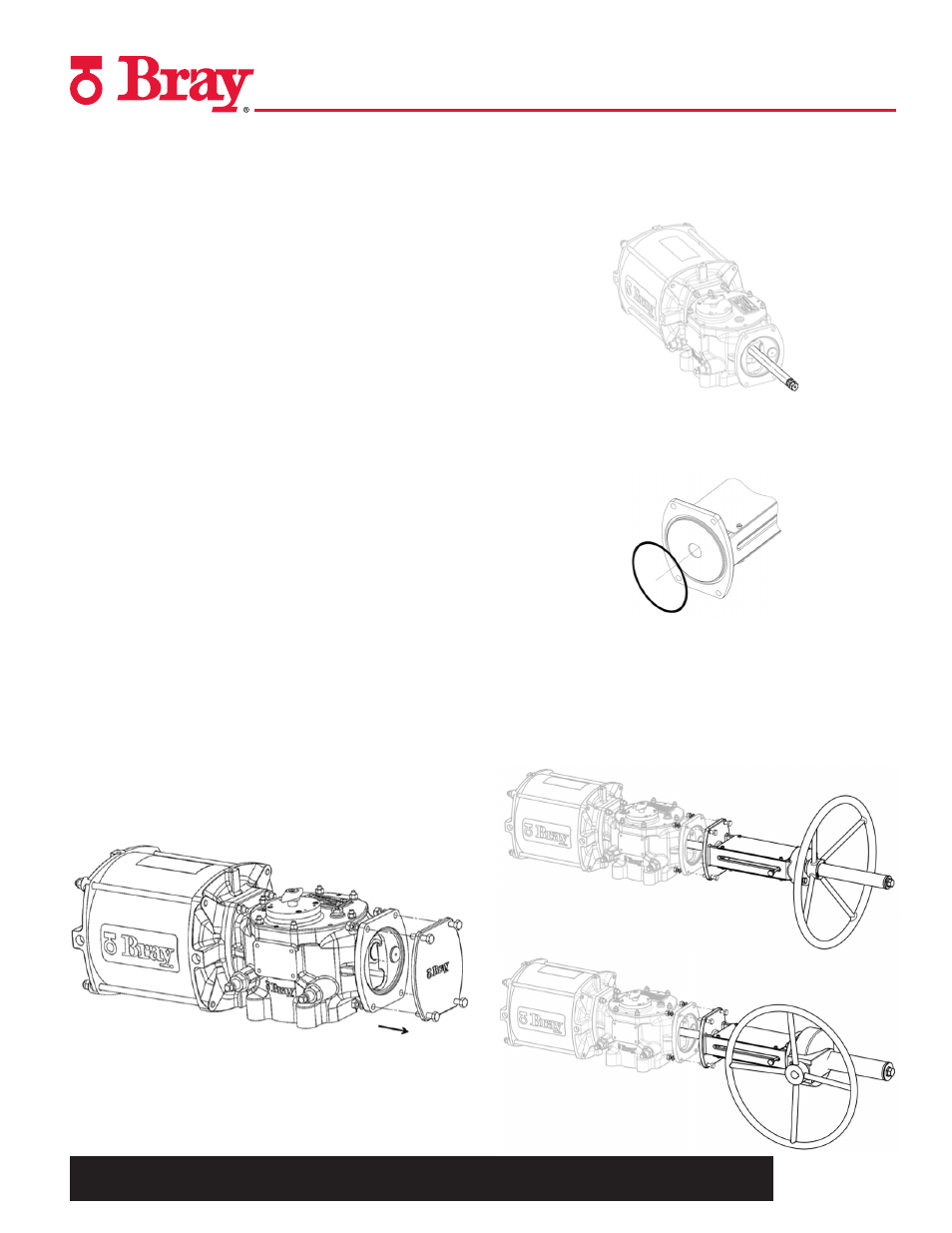

16.0 Jackscrew Override

Jackscrews provide an economical manual override option on the

actuator for use in case of air failure. These jackscrews come in

two types, direct hand wheel operated and bevel gearbox driven.

The direct hand wheel jackscrew has a rotating screw threading

into a bronze nut when installed on the Torque module of DA

actuators and on the Spring module of Spring Return actuators.

The hand wheel directly turns the screw or nut to move the

jackscrew forward or back.

The bevel gearbox driven jackscrews are required to reduce the

manual effort on larger actuator models and stiffer springs that

require higher thrust to compress. Here the screw translates with

an anti-rotation arrangement.

16.1 Installation

Jackscrew overrides are usually factory installed on the actuator.

Override units are shipped with the jackscrew assembly installed

on the actuator so that the actuator is ready for installation in

the auto operation mode. No additional customer installation is

required.

If a field retrofit is required on actuators without a manual over-

ride, the installation instructions provide a guide for a qualified

technician to install and operate the Jackscrew overrides.

16.1.1 Installing DA Jackscrew Override

1. Disconnect the air pressure and the electrical power from

actuator.

2. Remove the DA end cover plate from the actuator.

3. Free the Extension Rod from the Jackscrew assembly, apply

a drop of medium strength thread lock compound on the

extension rod threads and firmly tighten it into the threading

in the Guide Block inside the Torque Module.

4. Coat the extension rod with NLGI2 grease.

5. Lubricate and place the flange O-ring into the groove on the

jackscrew assembly flange

6. Back off the jackscrew fully in the assembly and carefully

slide the mounting flange of the jackscrew assembly on the

extension rod. Take care in locating the bushing and the

flange seal on the extension rod.

7. Slide the assembly to locate and mate the flanges. Use the

hardware supplied in the kit to fasten the assembly to the

Torque Module flange.

Direct Drive Ja

ckscrew -DA

Gear Drive Ja

ckscrew -DA