0 series 98 general specifications, Series 98 operation & maintenance, S98 o & m : 26 – Bray 98 Series User Manual

Page 26

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 26

Series 98 Operation & Maintenance

14.0 Series 98 General Specifications

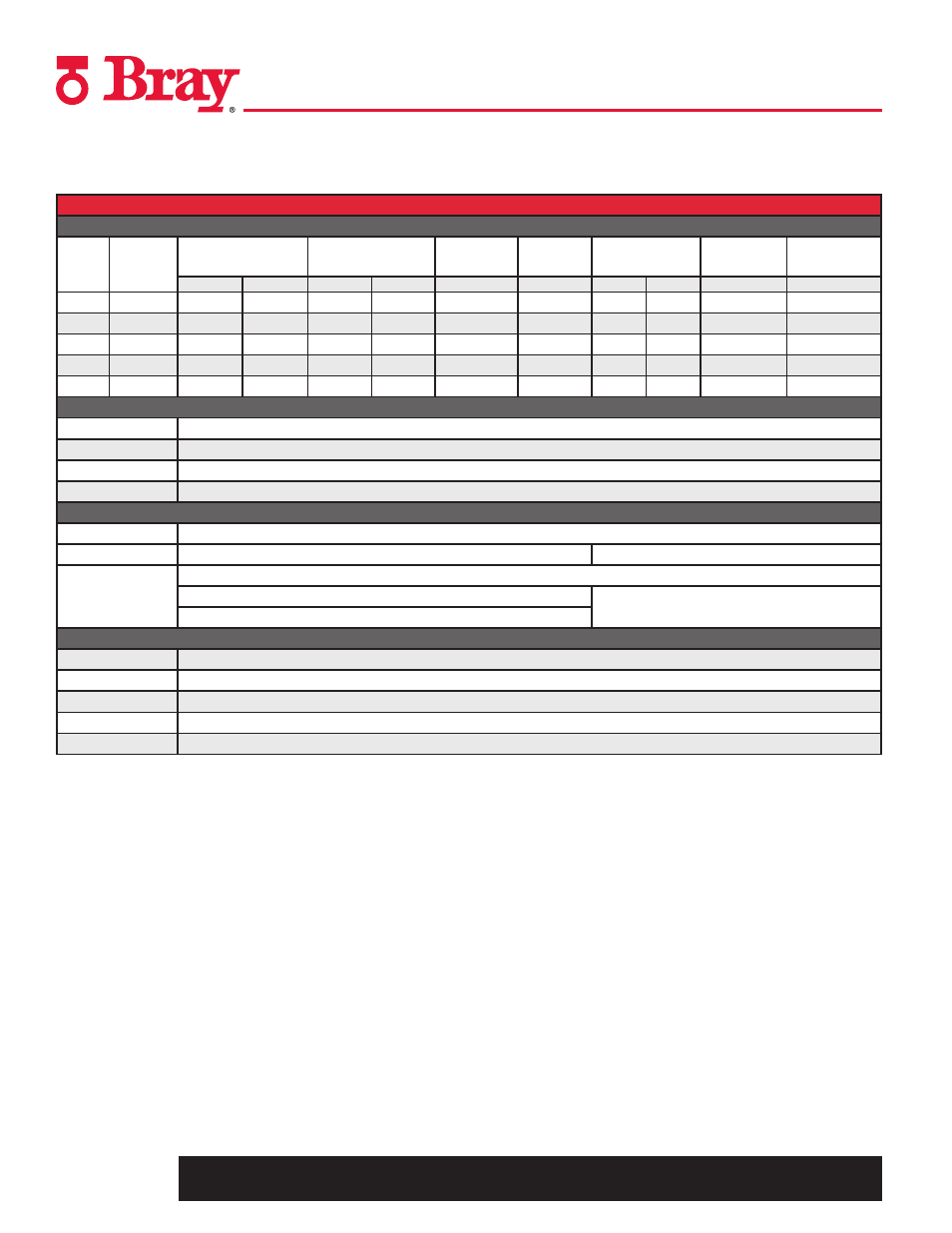

GENERAL SPECIFICATIONS

RANGE

Model

ISO

Mounting

Base

Rated Torque

Spring End Torque

Nm

Largest

Cylinder Size

MOP

DA- Symm

Maximum

Stem Acceptance

Diameter

Maximum

Stem Height

Over Travel

(on either side)

Nm

Lb-in

Min

Max

inch

psi

mm

inch

mm

± degrees

45 E2

F12/F16

4,500

39,830

1,070

2,675

14

59

50.0

1.97

183

5

73 E2

F12/F16

7,300

64,612

2,130

4,280

16

60

63.5

2.50

216

5

14 E3

F16/F25

14,000

123,914

3,485

7,845

20

62

76.2

3.00

240

5

24 E3

F25/F30

24,000

212,424

6,555

15,150

24

55

114.3

4.50

295

3

45 E3

F30/F35

45,000

398,295

11,950

25,595

28

62

152.4

6.00

318

3

CONFIGURATIONS

DA

Double Acting- Single Cylinder

DD

Double Acting- Dual Cylinders

SC

Spring Return- Fail CW

SO

Spring Return- Fail CCW

OPERATING CONDITIONS

Pressure Range

40 - 150 psi

Media

Dry Compressed Air / Natural Gas

Contact factory for other media

Temperature Range -

Standard Options

Standard : -20°F to 200°F (-29°C to 93°C)

High Temp : Up to 300°F (149°C)

Contact factory for extended ranges

Low Temp : Down to -50°F (-46°C)

COMPLIANCES

Torque Base

Mounting dimensions options per ISO 5211: 2001(E) or MSS SP-101-1989

Accessories

Shaft Driven Accessories Mounting as per NAMUR-VDE

Testing

In accordance with EN 15714-3:2009

Ingress Protection

IP66/IP67M per IEC 60529

Safety

ATEX, SIL 3