Series 98 operation & maintenance, 2 operation - spring return hydraulic override, 2 installing hydraulic override on da actuator – Bray 98 Series User Manual

Page 28

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 28

Series 98 Operation & Maintenance

MOP for SR Hydraulic Overrides

Model

MOP

Spring Number

1

2

3

4

5

73 E2

psi

1730

2045

2630

2980

bar

119

141

181

205

14 E3

psi

1445

1660

1930

2460

2930

bar

100

114

133

170

202

24 E3

psi

1400

1670

2125

2450

2815

bar

97

115

147

169

194

45 E3

psi

1290

1535

1765

2020

2340

bar

89

106

122

139

161

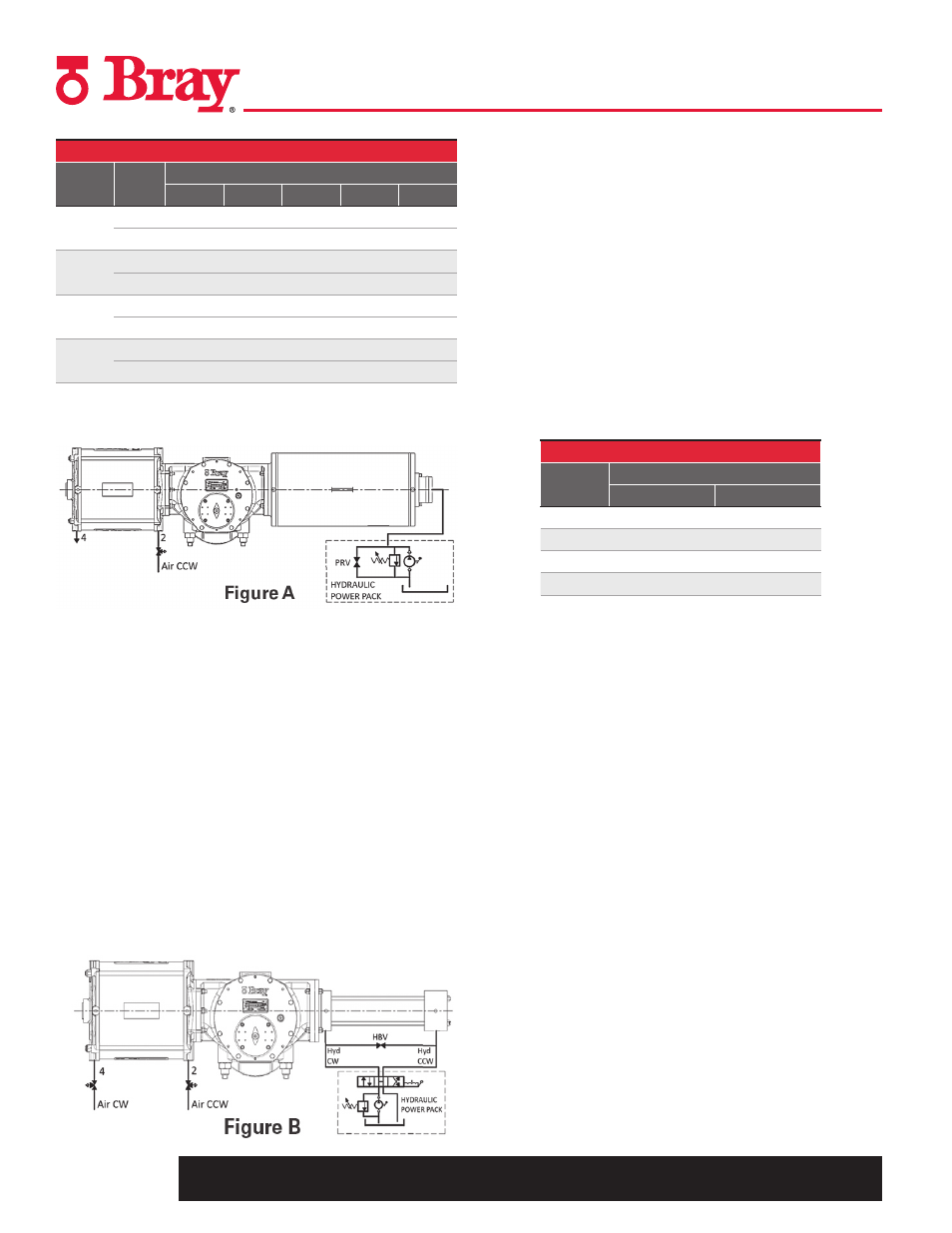

15.1.2 Operation - Spring Return Hydraulic

Override

1. To operate the override, turn the 3/2 way valve on the pressure

module to vent the cylinder port to atmosphere and Close

the pressure release valve (PRV) on the hand pump manifold.

Operating the Hand Pump on the power pack extends the

ram, pushes the Spring Rod while compressing the spring

and operates the actuator manually.

2. Opening the pressure release valve relieves the hydraulic

pressure to reservoir. The spring returns the ram of override

cylinder to retracted position and the actuator to fail safe

position.

3. To restore normal Automatic operation, turn the pressure

release valve to full Open and switch the 3/2 way valve on

pneumatic cylinder, to connect the cylinder port to the air

supply pressure.

15.2 Installing Hydraulic Override on DA Actuator

1. Turn the actuator so that the guide block is at the cover end

side of the Torque Module and ensure it stays in this position

after disconnecting air pressure and electrical power from

actuator.

2. Remove the DA cover plate from the torque module and

mount the DA hydraulic override cylinder assembly with the

hardware supplied in mounting kit. Make sure to install the

flange O-ring.

3. Remove the end cap of the hydraulic cylinder. With a suitable

socket/tube spanner located on the hex head of the hydraulic

piston end, thread and tighten the piston rod into the

threading on Guide Block inside the Torque Module. Refer

to the table below for tightening torque.

Piston Rod Tightening Torque

Model

Torque

Lb-ft

Nm

73 E2

110

150

14 E3

130

180

24 E3

130

180

45 E3

150

200

4. Replace the end cap, taking care not to damage the cap seal,

and tighten the tie rod nuts of the hydraulic cylinder.

5. Install the 3-way valves, rated for 150 psi (10.3 bar) working

pressure, on the pneumatic cylinder ports (Refer to Figure B)

and turn them to venting position.

6. Mount the hydraulic pump assembly on the Torque Module’s

rear accessories pad, as described in previous section.

7. Tube the ports of the hydraulic cylinder to the direction

control valve’s ports, on the hydraulic hand pump unit.

(Refer to Figure B)

8. Turn the direction control valve on the hand pump unit

to direct oil flow to one of the cylinder ports. Loosen the

corresponding vent plug on the cylinder and stroke the hand

pump to vent out air in the lines. Tighten the vent plug when

no more air bubbles are seen. Repeat the same for the other

side of the cylinder.

9. Check and ensure the Hydraulic pressure setting of the pump

does not exceed the MOP setting, refer to the table on page

27. Use the plugged port on the pressure line Tee to connect

a suitable pressure gage.