0 hydraulic override, Series 98 operation & maintenance – Bray 98 Series User Manual

Page 27

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of

BRAY INTERNATIONAL, Inc. The technical data herein is for general information only. Product suitability should be based solely upon customer’s

detailed knowledge and experience with their application.

S98 O & M : 27

Series 98 Operation & Maintenance

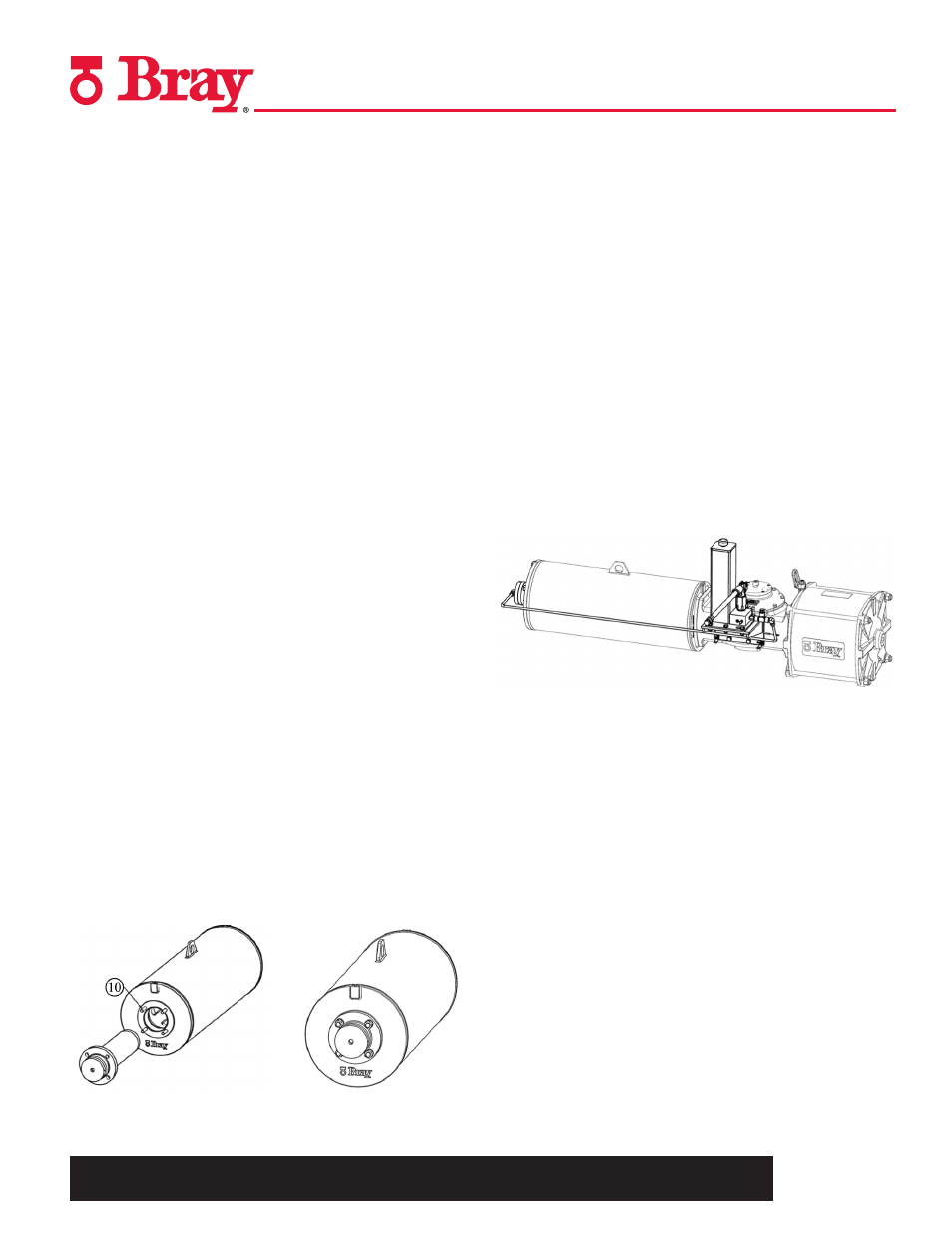

15.0 Hydraulic Override

Hydraulic overrides on S98 actuators provide low effort, high

thrust in a compact size for manually operating the actuator.

The hydraulic override cylinders are single acting on the SR

models and double acting on the DA models of the Actuators.

These are available on Models 73E2 through 45E3.

The hydraulic override consists of a power pack with a hand

operated high pressure pump and oil reservoir connected by

tubing to the hydraulic override cylinder. The hydraulic cylinder

is mounted on the Spring Module end thrust base on SR models

and on the Torque Module flange on the DA models.

The hydraulic override cylinders are designed for 3,000 psi max

working pressure and provide adequate thrust to output the

required valve torque. The operating pressure required is set on

the hand pump assembly through a built-in relief valve.

15.1 Installation

Series 98 standard actuators with hydraulic overrides are shipped

pre-assembled with the cylinder, hand pump, bypass valves and

tubing complete. The hand pump unit is selected, factory installed

and the hydraulic pressure valve set per the application. No addi-

tional customer installation/adjustment is usually required.

Actuators in service, without this override option, can be retrofit-

ted with the override kit as described below.

15.1.1 Installing Hydraulic Override on Spring

Return Actuators

1. Disconnect air pressure and electrical power from actuator.

2. In fail safe position of the actuator, remove the end cover

plate retaining the O-ring on the Spring Module end.

3. Firmly thread the studs (10) supplied with the override

mounting kit, into the thrust base. With the ram fully

retracted, insert the Hydraulic Cylinder into the Spring

Module mating the cylinder flange to the thrust base while

positioning the air venting plug at the top.

4. Secure the cylinder flange on the thrust base of the Spring

Module with the spring washers and nuts from the override

mounting kit.

5. Thread in the hydraulic connector into the cylinder port

(if not already fitted into the cylinder). Use a commercial

hydraulic fitting thread sealant (Loctite 542 or equivalent).

6. Fit a 3-way valve, rated for 150 psi (10.3 bar) working

pressure, to the pneumatic module’s port (Refer to Figure A

on page 26).Turn the valve to venting position so that the

pneumatic cylinder’s port is connected to atmosphere.

7. Fit the hydraulic hand pump assembly bracket on the rear

accessories mounting pad of the Torque Module with the 4

bolts supplied in the kit. Tube the cylinder port to the pump

outlet port, as in Figure A. The standard mounting, as shown,

is for the actuator in horizontal orientation. Special brackets for

other orientations of the actuator can be supplied upon request.

8. On the Tee at the pump outlet, remove the plug and install a

suitable pressure gage (0-4000psi).

9. Fill the hand pump reservoir to the required level with

hydraulic fluid (ISO 32 grade for general application). Install

the breather cap on the reservoir (do not substitute the

breather cap with a plug). Stroke the pump a few times with

the pressure release valve on the pump open to bleed air out

of pump.

10. Lightly loosen the air vent screw on the cylinder flange to

bleed off air from the hydraulic lines. Close the pressure

release valve on the pump and stroke the hydraulic pump till

the pressure builds up. Tighten the vent plug when no more

air bubbles bleed out. The ram advances to press against

the Spring Rod’s end face and the thrust from the hydraulic

cylinder ram effects the override function.

11. Note the maximum hydraulic pressure setting for the

actuator model (refer to the MOP table on page 26). Check

the hydraulic pressure on the gage at the end of the actuator’s

stroke. Refer to the hand pump service manual and adjust

the overload valve setting on the pump to the MOP.