Model mp, mpa, mpai, Description, 1 models – Xylem MPAI User Manual

Page 79: 2 shaft sealing, 3 bearings, 4 approximate value for sound pressure level

Installation, Operating and Maintenance Instruction

Model

MP, MPA, MPAI

MP 100-english

page 75

Revision 04

Article No 771074011

Issue 11/2011

3. Description

3.1 Models

Design MP: Horizontal shaft with bearings at both

ends, drive end at discharge side (standard), rotation

clockwise with suction branch left and discharge

branch radially upwards. Grease lubrication.

Optional:

Suction branch right or radially upwards,

discharge branch left or right, drive-end at suction side

(rotation anti-clockwise).

Design MPA: Endsuction type, discharge branch

radially upwards. Drive end at discharge side. Thrust

bearing at drive side, grease lubrication, medium

lubricated slide bearing between first and second

stage.

Optional:

Discharge branch left or right.

MPAI Design: As the MPA design, but also with an

inducer.

The pumps are designed as modular systems and

can, therefore, be delivered in many variants (e.g.

different materials, shaft sealings, different kinds of

lubrication, cooling / heating, a.s.o.).

The permitted application conditions and design

details of the delivered pump are shown in the

attached data sheet and / or order confirmation.

3.2 Shaft Sealing

Basically there are two kinds of shaft sealing: the

packing and the mechanical seal, whereas, there

again are many variants of both kinds. At the data

sheet and / or the order confirmation the shaft sealing

type of your pump is shown.

Instructions for packing a gland can be found in

Section 7.3 and instructions for installation and

operation of mechanical seals in Section 8

"Disassembly of the Pump and Repair".

Further details about packing and mech. seals,

as well as the therewith connected accidental

dangers, you can find in chapter 6.6 and in

chapters 7.2 and 7.3.

In areas endangered to explosion the use of

pumps with packing is forbidden!

3.3 Bearings

Design MP: Bearings at both ends; thrust bearing at

discharge side, ball bearing at suction side.

Lubrication: Grease lubrication (standard design) with

relubricating mechanism (lubricating nipple).

Design MPA, MPAI: Thrust bearing at discharge side,

medium lubricated slide bearing between first and

second stage at suction side.

Lubrication: Grease lubrication (standard design) with

relubricating mechanism (lubricating nipple).

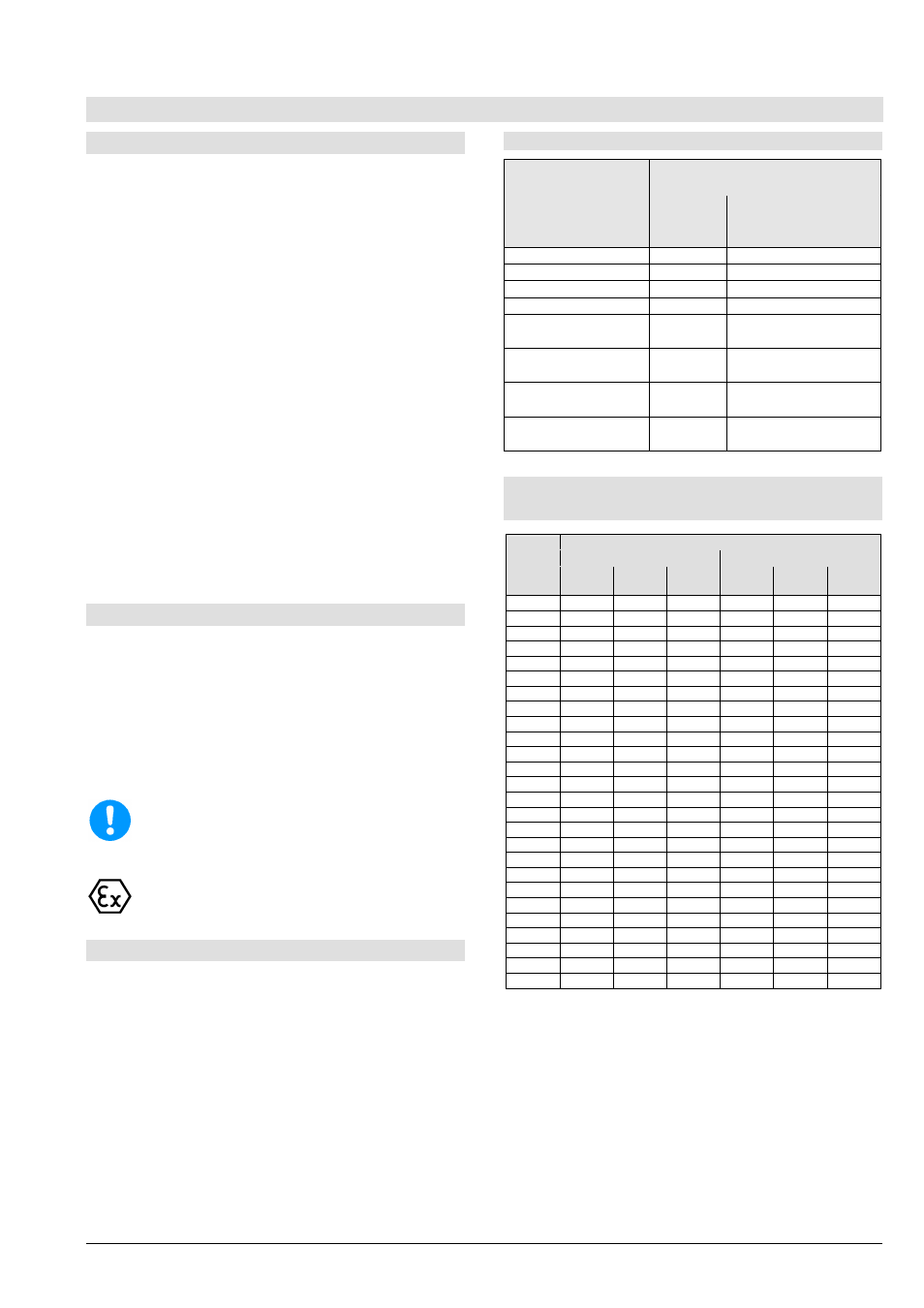

Bearing types

Pump size

Grease lubrication

Bearing type

Suction

side

(only MP)

Discharge side

(MP, MPA, MPAI)

MP/MPA/MPAI 40.2

6306-C3

3306-C3

MP/MPA/MPAI 40.3

6306-C3

3306-C3

MP/MPA/MPAI 65.1 6307-C3

3307-C3

MP/MPA/MPAI 65.2 6307-C3

3307-C3

MP/MPA/MPAI 100.1 6308-C3

2x 7308

(X-

arrangement

)

MP/MPA/MPAI 100.2 6308-C3

2x 7308

(X-

arrangement

)

MP/MPA/MPAI 125.1 6310-C3

2x 7310

(X-

arrangement

)

MP/MPA/MPAI 125.2 6310-C3

2x 7310

(X-

arrangement

)

3.4 Approximate Value for Sound

Pressure Level

Nominal

power

P

N

in kW

Sound pressure level L

pA

in dB(A)

Pump alone

Pump + Motor

2950

min

-1

1450

min

-1

975

min

-1

2950

min

-1

1450

min

-1

975

min

-1

1,5

66,7

65,8

65,3

68,2

66,0

65,5

2,2

68

67

66,5

69,2

67,2

66,7

3

69

68,1

67,6

71,5

68,3

68,5

4

69,9

69

68,5

72,1

69,2

69,2

5,5

71

70

69,5

73,1

70,4

70,1

7,5

71,9

71

70,5

73,7

71,3

71,8

11

73,3

72,3

71,8

75,0

73,2

72,8

15

74,2

73,3

72,8

75,6

74,0

74,0

18,5

74,9

74

73,5

76,1

74,6

76,3

22

75,5

74,5

74

77,1

75,1

76,5

30

76,5

75,6

75,1

77,8

76,1

75,7

37

77,1

76,2

75,7

78,3

76,8

76,4

45

77,9

76,9

76,4

79,4

77,4

76,8

55

78,5

77,5

77

80,1

78,0

77,3

75

79,4

78,5

78

81,4

78,9

78,4

90

80,1

79,1

78,6

81,8

79,4

79,0

110

80,8

79,8

83,4

80,2

132

81,3

80,4

83,7

80,8

160

81,9

81

84,1

81,3

200

82,7

84,6

250

83,4

86,2

315

84,1

86,6

355

84,6

86,9

400

84,9

87,1

450

85,4

87,4

500

85,6

88,3

Sound pressure level L

pA

measured in 1 m distance

from pump surface acc. to DIN 45635, part 1 and 24.

Room and foundation influences are not considered.

The tolerance for these values is ±3 dB(A).

Addition with 60 Hz-operation:

Pump alone: −

Pump with motor: +4 dB(A)