Xylem GLS GLV User Manual

Page 28

en

28

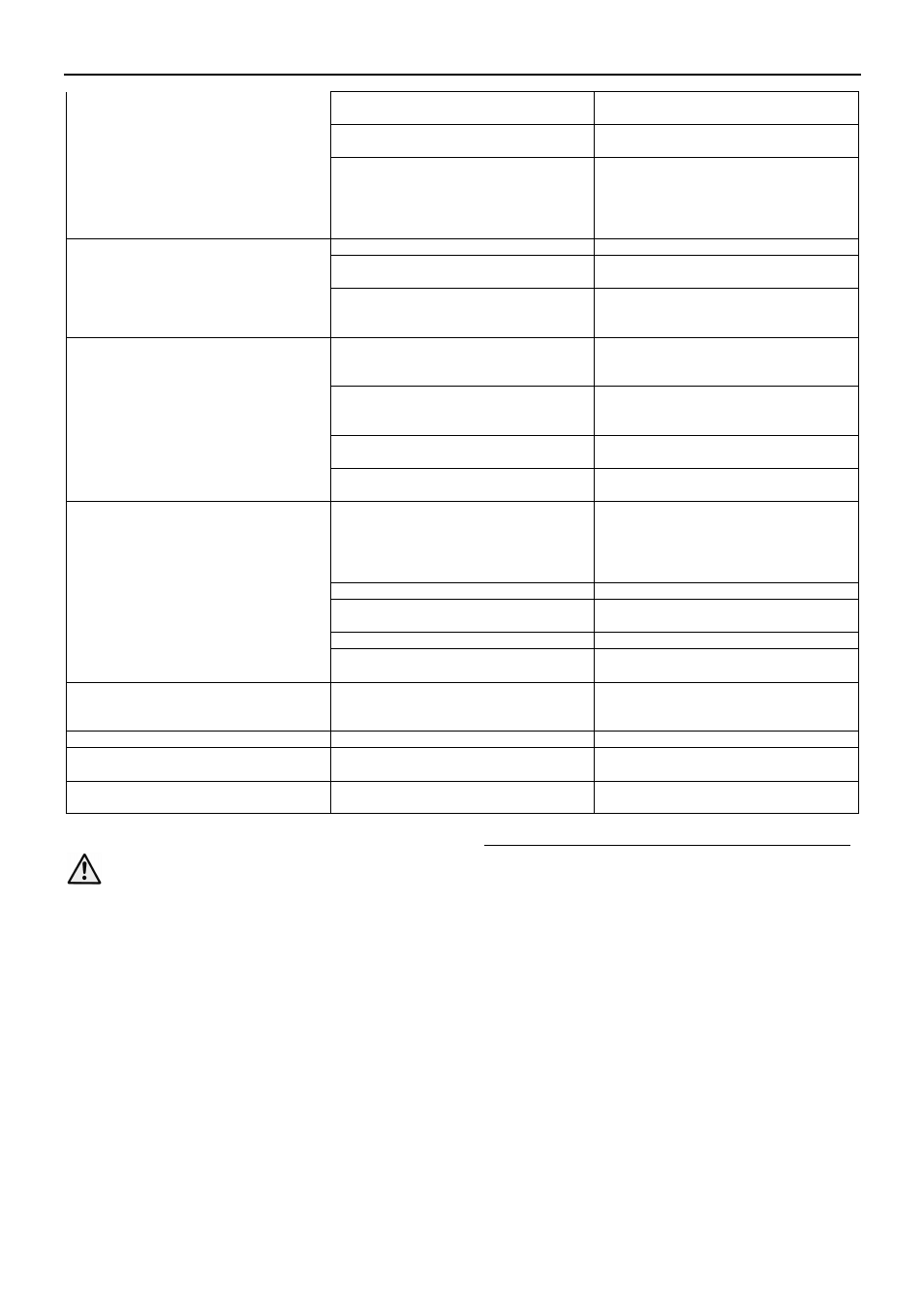

triggered or the fuses blow.

Thermal protector or fuses not suited to

the motor current.

Check the components and replace as

necessary.

Motor overload.

Check the operating conditions of the

electric pump and reset the protection.

Wrong rotation direction.

Check the direction of rotation and, if

necessary, exchange two phases in the

electrical panel if the pump is a three-

phase model, or check all the

connections if it is a single-phase model.

A phase in the power supply is missing. Check the power supply.

The electric pump starts up but, after a

short period of time, the thermal

protector is triggered or the fuses blow.

Power supply voltage not within the

motor’s working limits.

Check the operating conditions of the

electric pump.

The electric panel is situated in an

excessively heated area or is exposed to

direct sunlight.

Protect the panel from heat sources and

from the sun.

There are foreign bodies (solid or fibrous

substances) inside the pump, the

impellers are jammed.

Extract the electric pump and clean it.

The electric pump starts up but, after a

varying period of time, the thermal

protector is triggered.

The pump is overloaded because it is

sucking a dense and viscous liquid.

Check the actual power requirements

based on the characteristics of the

pumped liquid.

The temperature of the sucked liquid is

too high.

Check the operating conditions of the

electric pump.

Worn motor bearings

Contact our Sales and Service

Department.

The electric pump starts up but does not

deliver the required flow.

Wrong rotation direction.

Check the direction of rotation and, if

necessary, exchange two phases in the

electrical panel if the pump is a three-

phase model, or check all the

connections if it is a single-phase model.

Air in the pipes.

Bleed the air.

Air in the pump.

Bleed the air and check the liquid level

( section 3.1.6).

Piping and/or pump clogged.

Disassemble and clean.

Valves locked in closed or partially

closed position.

Disassemble and clean, if necessary

replace the valve.

The electric pump starts up but it does

not stop.

Failure of start/stop device (float).

Check the water level in the tank. If

everything is in order, check the device

and its connection cables.

The system’s general protection cuts in. Short circuit.

Check electrical system.

The system’s differential thermal-

magnetic protection cuts in.

Ground leakage.

Check insulation of the electrical system

components.

The pump rotates in the wrong direction

when it is stopped.

Leaks in check valve

Repair or replace the components.

9.

Disposal

Information for installation and maintenance personnel

Observe the regulations and codes locally in force regarding sorted waste disposal.