Xylem GLS GLV User Manual

Page 26

en

26

Pay attention that the electric pump may start without prior notice.

Verify that the safety equipments are always active. Observe all the accident prevention regulations.

Check the current absorbed by the motor and, if necessary, adjust the setting of the thermal relay.

Make sure that the level of the liquid is high enough to prevent inlet of air to the pump through the

suction port.

6.4

Distance to wet areas

Risk of electrical shock when pumping near a lake, beaches, jetties, beaches or similar wet areas. There

must be a safety distance of at least 20 meters between the person and the electric pump if the person is

in contact with the pumped liquid.

Do not use the electric pump for swimming pools or fountains.

7.

Maintenance, service and spare parts

Information for maintenance personnel

Before performing any maintenance operations on the electric pump, make sure that the motor is

voltage-free.

Maintenance operations must be performed by skilled, qualified and authorized personnel only. Use

suitable equipment and protection devices. Observe the accident prevention regulations in force. If you

need to drain the pump, make sure that the drained liquid does not cause damage or injuries.

Wait for all the components to cool down before touching it.

During maintaining and before reassembly, always remember to clean carefully all the components, in particular O-rings seats,

and to replace all the O-rings, the gaskets and the sealing faces of the seals.

7.1

Routine maintenance

The pump requires a few simple routine maintenance tasks to be performed on a regular basis.

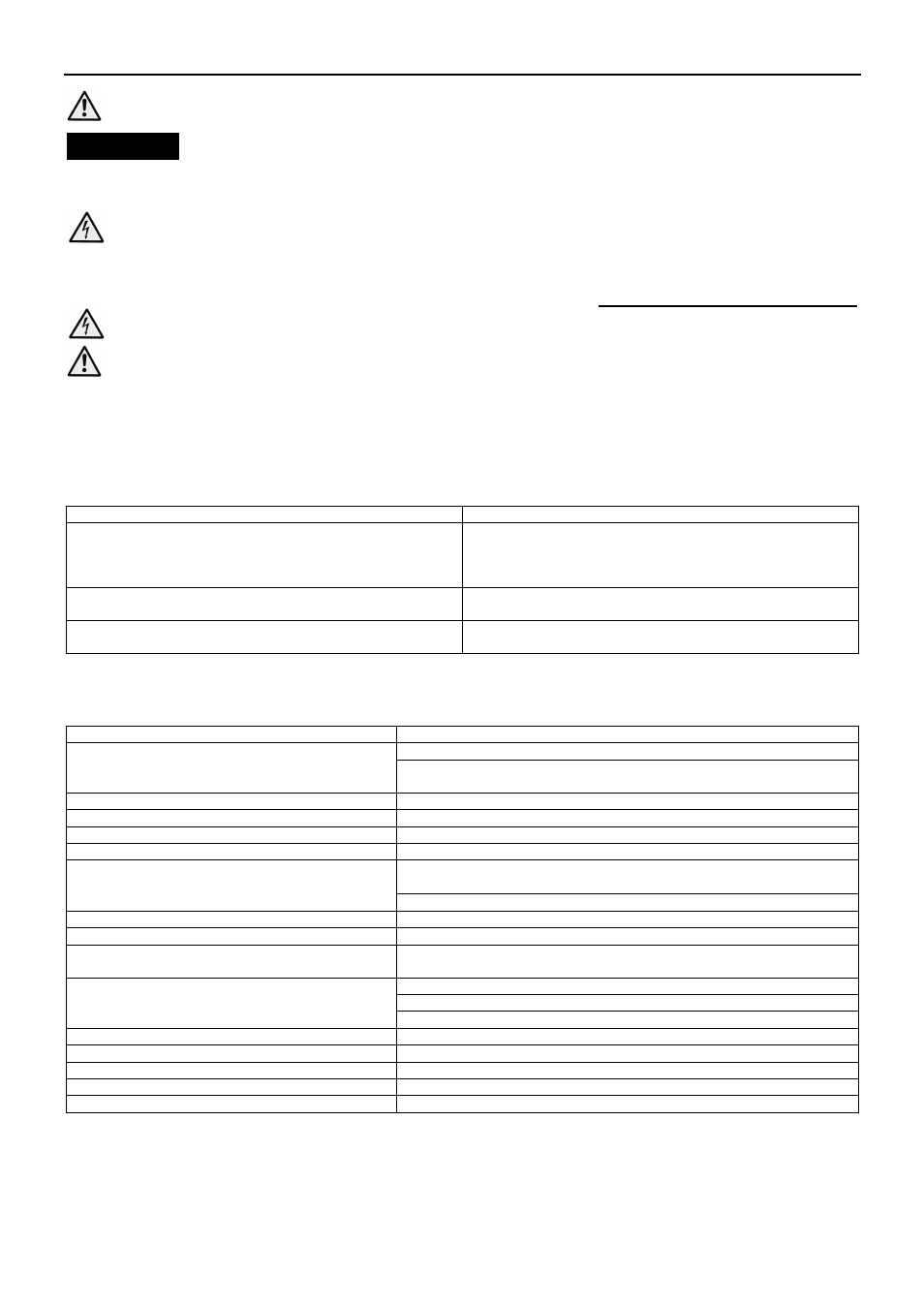

Frequency*

Operation

Within the first year of operation

Initial inspection.

Ask our Sales and Service Department for a check of the

electric pump conditions to determine the frequency of

maintenance inspections.

At least once a year for normal applications and operation in

liquids with temperature < 40°C.

Periodical inspection to avoid operation breakdowns and

failures.

At least once every 3 years for normal applications and

operation in liquids with temperature < 40°C.

Major inspection to ensure a long electric pump operating

lifetime.

* more frequent operations may be necessary if the electric pump is used in extreme conditions, like for example pumping

abrasive or corrosives solids, or liquids with temperature > 40°C.

7.1.1

Initial and periodical inspections

Component to be inspected

Operation

If the outer jacket is damaged, replace the cable

Electric cable

Check that the cables do not have any sharp bends and are not

pinched.

Electrical connections

Check that the electrical connections are properly tightened.

Electrical cabinets

Check that they are clean and dry.

Impeller

Check the impeller clearance. If necessary, adjust the impeller.

Stator casing*

Drain all liquid, if present.

Check that the insulation resistance between the ground and the phase

lead is more than 5 MΩ.

Insulation

Check the resistance between phases.

Terminal board box

Check that it is clean and dry.

Lifting device

Check that local safety regulations are followed.

Lifting handle

Check the screws. Check the conditions of the handle. Replace if

necessary.

Replace the oil plug O-rings.

Replace the O-rings on the terminal board cover.

O-rings

Grease the new O-rings.

Personal safety devices

Check all the protections.

Rotation direction

Check the rotation direction.

Oil housing

Fill with new oil, if necessary.

Terminal board / closed end splice

Check that the connections are properly tightened.

Voltage and amperage

Check the values.

* regardless of the individual application, the inspection chamber should be inspected at least with the same frequency than

the intervals for normal applications and conditions with liquids having temperature < 40°C.

WARNING