Xylem Fire diesel pump D Series GEN D Series User Manual

Page 46

46

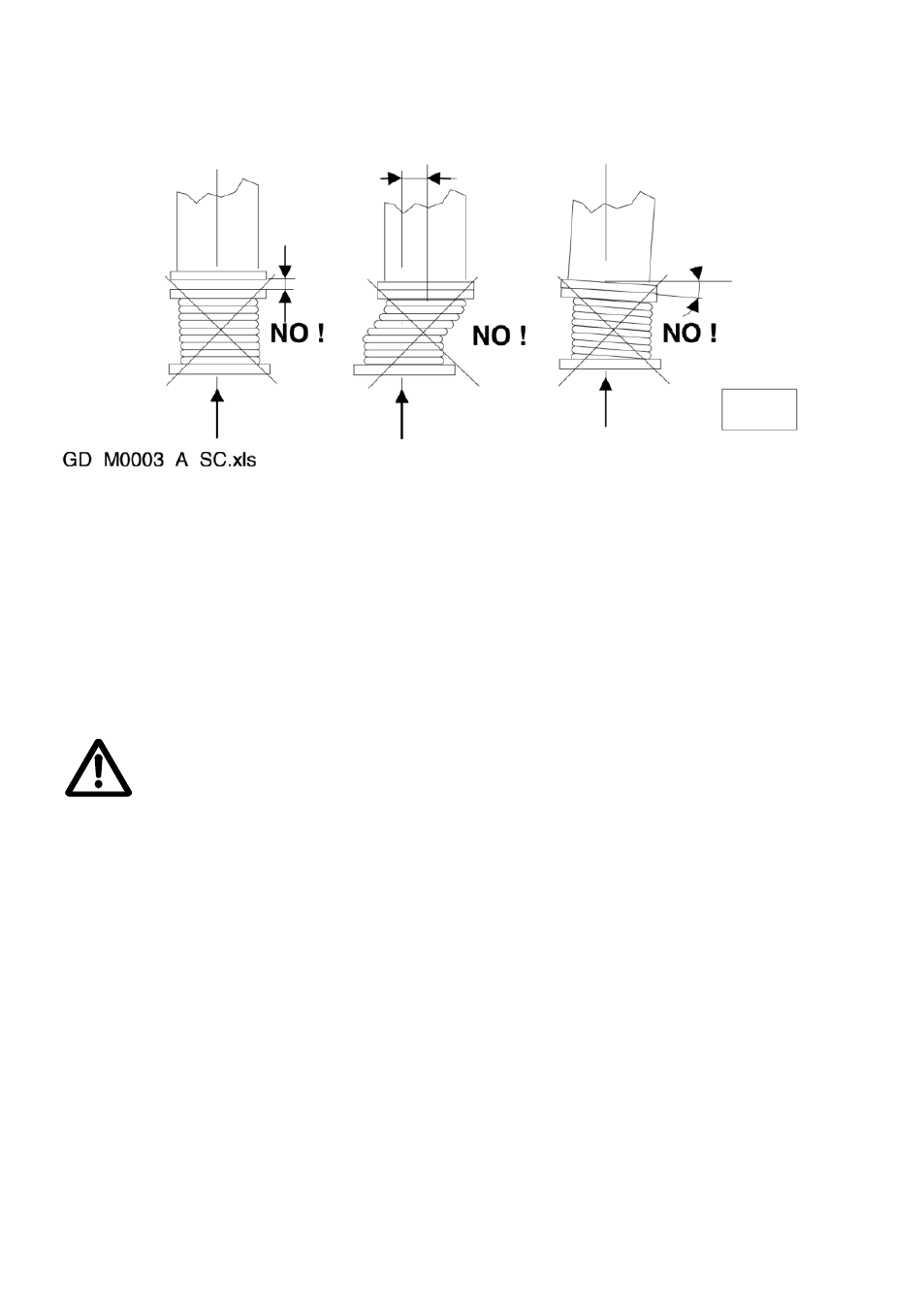

FUME EXHAUST PIPING RUBBER EXPANSION JOINT

Observe the maximum values specified by the manufacturer of the rubber expansion joint.

For long sections of piping, expansion joints consisting of flexible sealed elements must be

mounted at appropriate intervals.

Do not install the pipes near the engine air filters. Suction of heated air must also be avoided.

Thermally insulate the pipes to prevent excessive heating of the room and accidental contact

with dangerously hot parts.

For applications with multiple explosion engines, the engine exhaust gases must not flow into

a single exhaust pipe, as problems may arise when one or more engines are running and the

exhaust gas generated by them is conveyed to the engines that are off.

Exhaust gases and fumes can be lethal! Do not run the engine without a suitable

supply of fresh air and discharge the gases into the atmosphere!

VENTILATION

Adequate ventilation of the room in which the diesel pump set is installed is very important

for proper operation and in order to guarantee:

-

The dissipation of the radiative heat generated by the set while running;

-

The proper flow of the air supply and the necessary amount for engine combustion;

-

The cooling of the engine through the radiator (for water-cooled engines) or though the

engine fan (for air-cooled engines);

A valid ventilation solution, suitable for most cases (water-cooled engines), is shown in figure

1, where the engine fan sucks the cooling air from the room while the hot air is expelled

through the radiator and vented outdoor.

The hot air from the radiator must not be allowed back into the room; therefore, you must

make sure that the air vent is properly isolated and sealed (solution valid for water-cooled

engines). This way, continuous air exchange in the room is guaranteed.

The sizing of the inlet openings must be calculated based on the sum total of the air flows

needed for cooling and combustion.

∆O

α

∆V

4