Inspection items chart – GE Industrial Solutions AF-300C AC Drive User Manual

Page 90

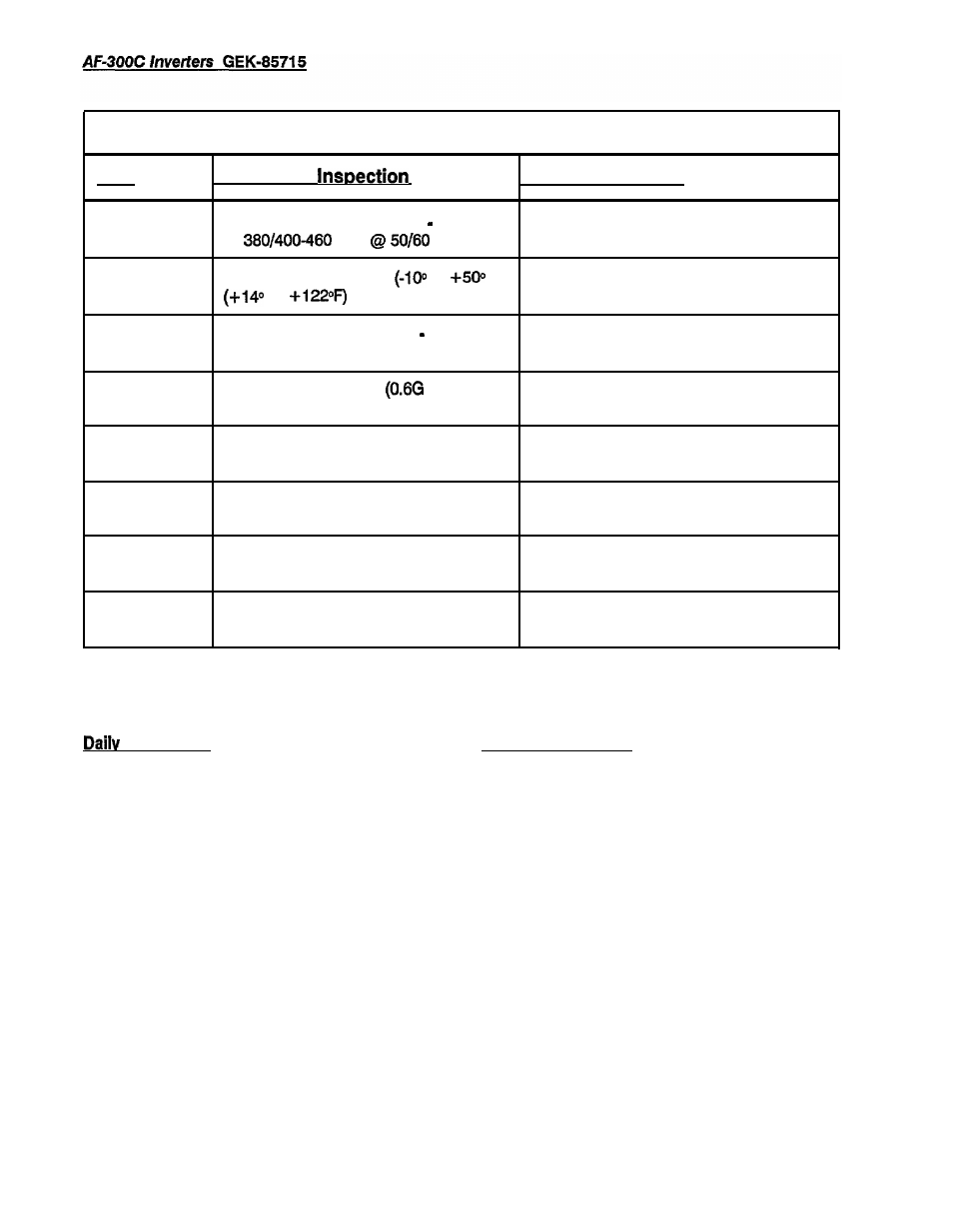

INSPECTION ITEMS CHART

Item

Reason of

Corrective Action

Power Source

Wiihin permissible limits (323 506 VAC)

Adjust the power supply voltage

Voltage

for

VAC

Hz.

Ambient

Within permissible limits

to

C)

Investigate cause and make corrections

Temperature

to

until environment is within permissible limits

Ambient

Wiihin permissible limits (20 90% RH)

Investigate cause and make corrections

Humidity

No dew condensation or freezing

until environment is within permissible limits

Vibration

Within permissible limit

or less)

Investigate cause and make adjustments

until within permissible limits.

Noise

Odor

Abnormal Audio Noise from cooling

fan, etc.

Smell or burning

Contact the supplier where the inverter

was purchased.

Contact the supplier where the inverter

was purchased.

Dust

Screws/

Connectors*

Dust accumulation on cooling fins,

Clean and blow out with compressed air.

cooling fan, or on the control board.

(Follow appropriate safety precautions.)

Check for any loosening

Retighten as needed.

*Check internal screws/connectors only during periodic inspections or when cover is removed.

Inspections

Periodic Inspections

For daily inspections, it is not necessary to remove

the inverter cover. Check the inverter from the out-

side for any abnormal items per the above chart.

-- If anything is found, take corrective action as soon

as possible.

-- If the inverter is to be kept in operation before cor-

rections can be made, record details of the prob-

lem for future reference.

Periodic inspection intervals will vary per the inverter

application (bi-monthly, semi-annualy, annually, etc.).

Pick an interval that best suits the particular applica-

tion, but do not ignore the inspections entirely.

For periodic inspections, remove the inverter cover

and check the inverter for any abnormal items as per

the daily inspections, plus the following:

-- Check all internal screws/connections.

-- Check the DC Link capacitor for any leakage or

swelling.

-- Check relay contacts for roughness.

-- Check all wires and conductors for any deforma-

tion or heat damage/deterioration.

-- Check resistor insulation for cracks.

-- Verify output voltage of each phase.

7-2