Optical considerations – OSRAM PrevaLED Core Z2 User Manual

Page 8

8

2. Optical considerations

OPTICAL CONSIDERATIONS

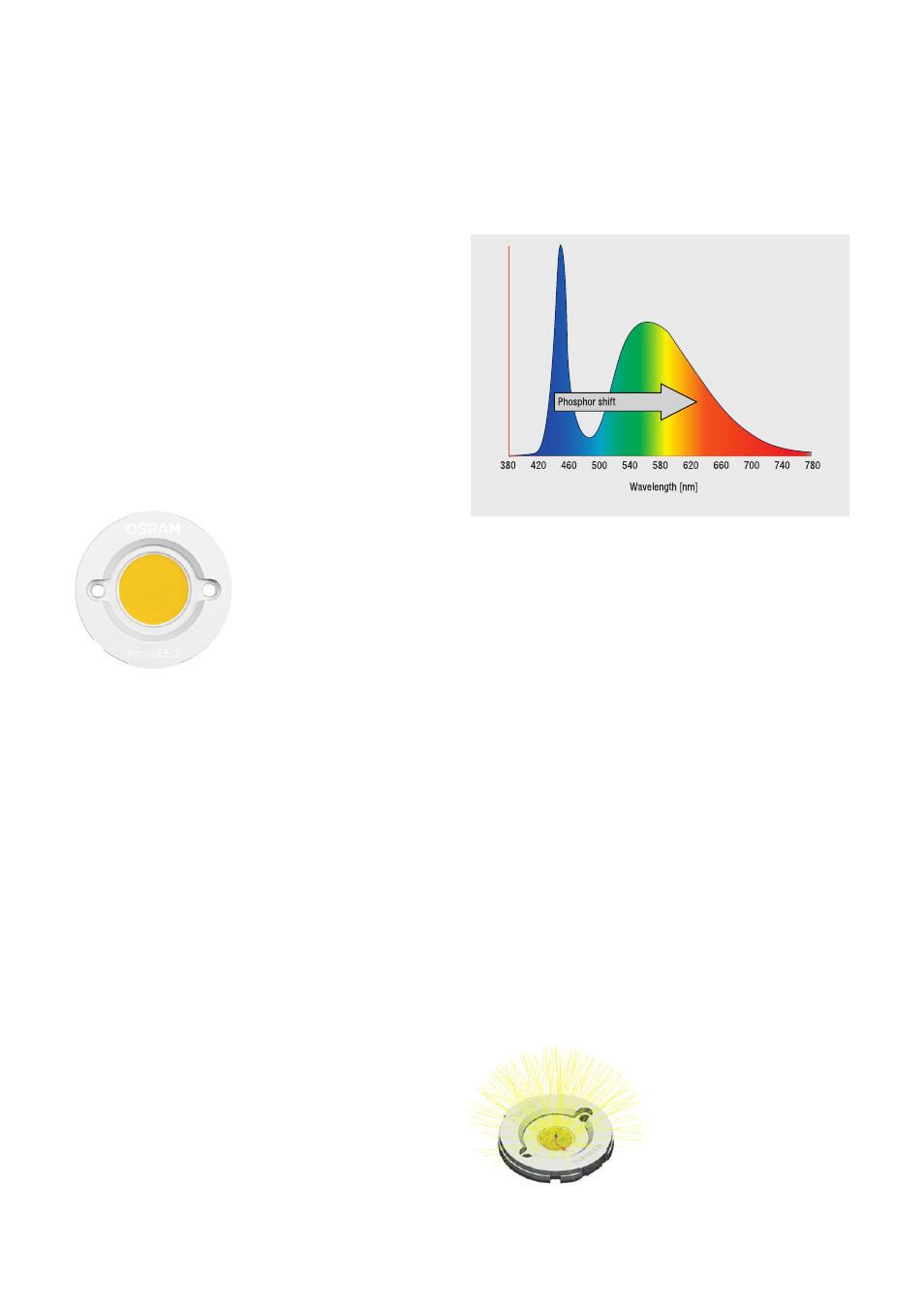

Chip-on-board-design (CoB)

So-called chip-on-board (CoB) light sources without

housing and with high-performance chips set very closely

next to each other have proven to be especially advanta-

geous. Due to the large amount of applied chips, the size

of the light source is fl exible and scalable. In the applica-

tion, the compactness, on the one hand, allows for very

high axis light and illumination levels, and, on the other

hand, a very high-contrast illumination with high brilliance.

Very good homogeneity (with a uniformity factor of 0.93) –

combined with constantly Lambertian radiation – addition-

ally simplifi es refl ector design and facilitates the inter-

changeability of light sources.

The CoB design is characterized by a large amount of

closely set LED chips, arranged in a certain grid which is

covered with luminescent material (cf. the image above).

One of the key advantages of this design is its very homo-

geneous light-emitting surface.

Pure phosphor conversion with CoB

Thanks to the use of pure phosphor conversion, the

PrevaLED

®

Core Z2 module can achieve a color rendering

quality of higher than CRI 90, while at the same time

providing a very homogeneous light output.

Phosphor conversion: By means of phosphor conversion, the blue

light of the LED chip is shifted towards the higher wavelengths of

green and red light.

PrevaLED

®

Core Z2

2.1. Refl ector

High luminous densities (1.5–4.5 Mcd/m

2

) are the key

factor for LED-based lamps and luminaires in the area of

refl ector applications such as spotlights, for example.

For these, light sources with small light-emitting areas

and a high luminous fl ux are required (as realized with the

PrevaLED

®

Core Z2), because that way, the light can be

collimated especially well with refl ectors.

Thanks to CoB technology, the PrevaLED

®

Core Z2 has

a uniform light-emitting surface which, due to its great

homogeneity, eliminates the need to use diffuser material.

The minimized light-emitting surface (LES) and a refl ector

positioning close to the LES allows for better optical

handling. All in all, the properties of the PrevaLED

®

Core Z2

allow for the prevention of roughness and facets, which in

turn allows for minimal overall beam angles of 10° or less.

The high homogeneity of the PrevaLED

®

Core Z2 means:

• Low complexity in the surface structure of the refl ector

• Narrower beam angles <10° FWHM in combination with

minimized light-emitting surface

PrevaLED

®

Core Z2