OSRAM PrevaLED Core Z2 User Manual

Page 16

16

THERMAL CONSIDERATIONS

4.2. Heat sink

Basically, the heat sink has to fulfi ll two tasks:

a) Heat spreading through heat conduction

The task here is to spread the heat as uniformly as possi-

ble from the contact surface of the LED module through

the heat sink material and into the cooling fi ns. In this

respect, the thermal conductivity and the material cross

sections of the heat sink play a decisive role (cf. the thermal

conductivities table below).

b) Heat dissipation to the surrounding medium

(usually ambient air)

For this task, the heat sink design in terms of fi n and sur-

face confi guration is decisive. By adequate geometrical

forming, heat conduction through convection and IR radia-

tion can be signifi cantly infl uenced and improved (cf. the

table with the IR emission coeffi cients on the next page).

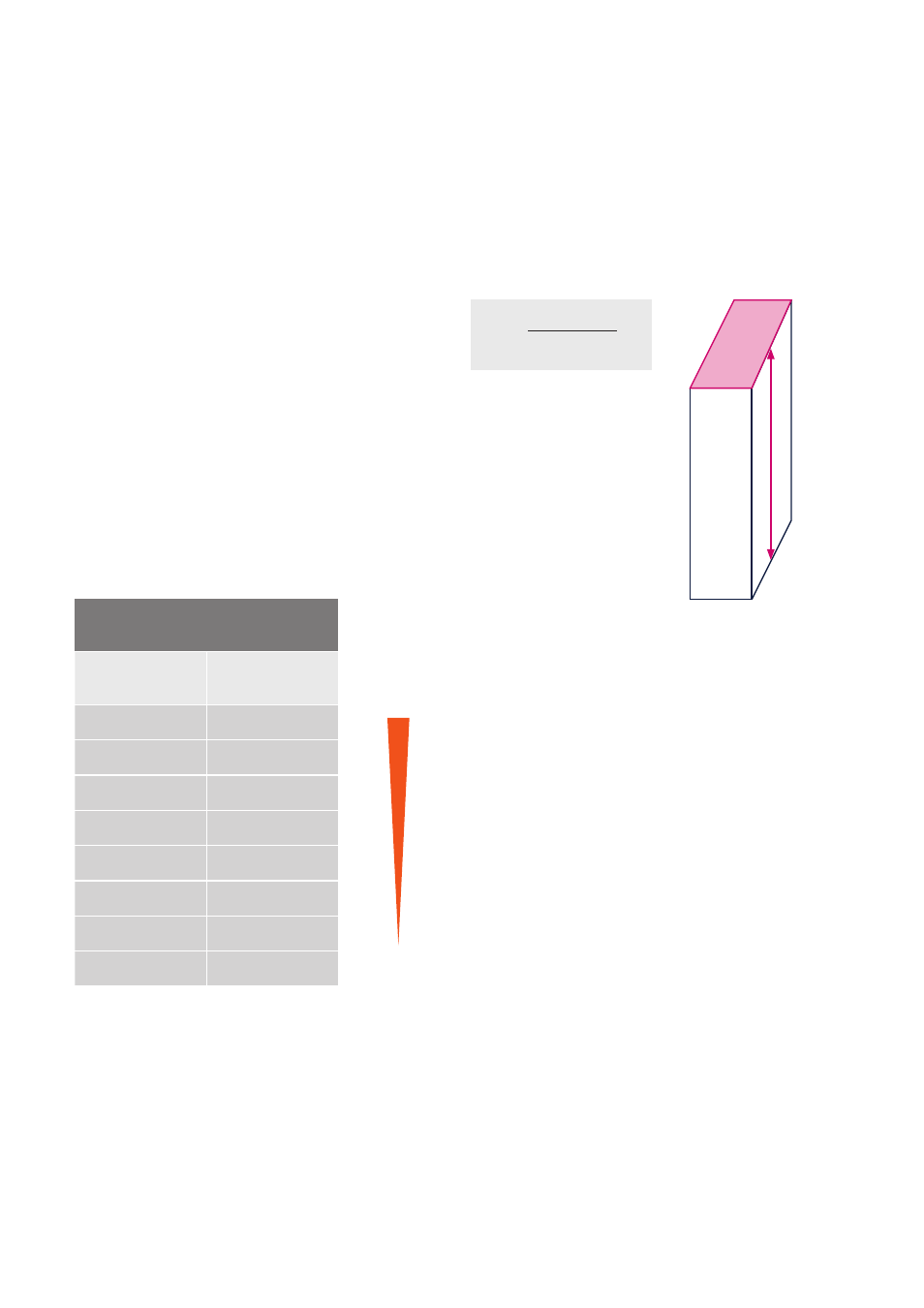

Thermal conduction

resistance (R

th

) formula:

R

th

=

L

A

·

A

L

Thermal conductivities of selected materials

Material

Specifi c heat

conductance value

[W/(m · K)]

Copper

380–401

Aluminium

200–220

Brass

120

Steel

42–58

Stainless steel

15

Glass

1

Wood

0.13–0.18

Air (dry at 1013 mbar,

no dissipation)

0.0256 at 20 °C

Very good heat

conduction

Bad/no

cooling

L: Length through the material in

fl ow direction

[m]

A: Material cross section/surface

of the heat sink

[m

2

]