Thermal considerations – OSRAM PrevaLED Core Z2 User Manual

Page 17

17

THERMAL CONSIDERATIONS

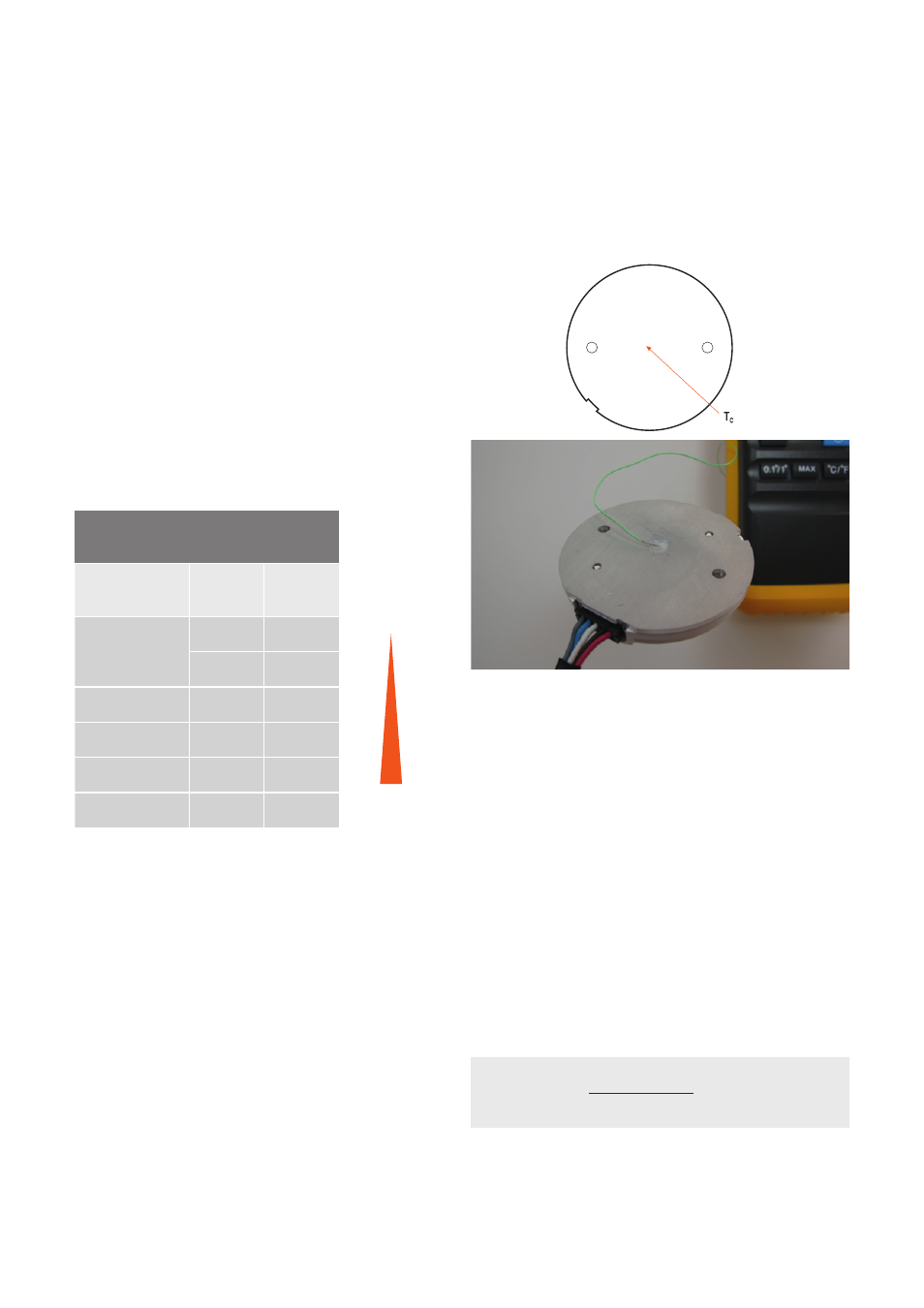

4.3. Temperature measurement

Measuring the temperature helps controlling the LED mod-

ule’s operating parameters. After fi xing the LED module

into the luminaire, the temperature has to be measured at

the thermal interface point (T

c

point), within the planned

ambient and operation conditions.

In order to do so, a thermocouple has to be affi xed to

the T

c

point, preferably by gluing (e.g. by means of a heat-

conducting adhesive such as “Arctic Silver”).

The thermal interface temperature (case temperature/T

c

) is

measured in the center of the back of the LED module, by

means of a thin milled channel (in the LED module or the

luminaire) or hole (

∅ approx. 2 mm) which is drilled into

the luminaire prototype for the thermocouple.

With this temperature measurement, as applied at the mea-

suring point of the LED module, the actual T

c

temperature

can be determined. By means of suitable cooling methods

(active or passive cooling), this temperature must be main-

tained under the maximum temperature specifi ed in the

datasheet.

Thermal interface point (T

c

point)

Overview of selected materials with

different surfaces

Material

Emission

ratio

⑀

Temperature *

[°C]

Aluminium plate,

blank, rolled

0.022

25

0.040

170

Aluminium, die-cast

surface, blank

0.4

170

Aluminium, black

anodized

0.600

40

Steel, powder-coated

0.85

25

Aluminium, matt

black fi nish

0.970

80

Low cooling

effect

High cooling

effect

*) Temperature of the material at which

the emission ratio was measured

T

c

is measured in the center of the back of the LED module

For necessary heat transfer and good cooling, the surface

of the applied heat sink material, with regard to heat

emission, must be considered. In order to achieve very

good radiation behavior to the ambient space, it can be

advantageous to use heat sinks with a matt black fi nish.

Within typical applications such as downlights in recessed

ceilings, it can be an advantage to use black anodized

heat sinks.

For the optimization of the radiation, special lacquers

with a high emission ratio, as typically used for radiators

instead of anodization, are available.

Based on the measured interface temperature (T

c

) of the

ambient temperature (t

a

) and the thermal module perfor-

mance (P

th,mod

), you can determine the necessary thermal

resistance of the cooling system (R

th

KS).

Formula for calculating the T

c

temperature

R

th

KS = Thermal resistance cooling system

T

c

= Temperature T

c

point

t

a

= Ambient temperature (usually air temperature of the room)

P

th, mod

= Thermal module performance

T

c

-t

a

P

th, mod

R

th

KS =