OSRAM PrevaLED Core Z2 User Manual

Page 22

MECHANICAL CONSIDERATIONS

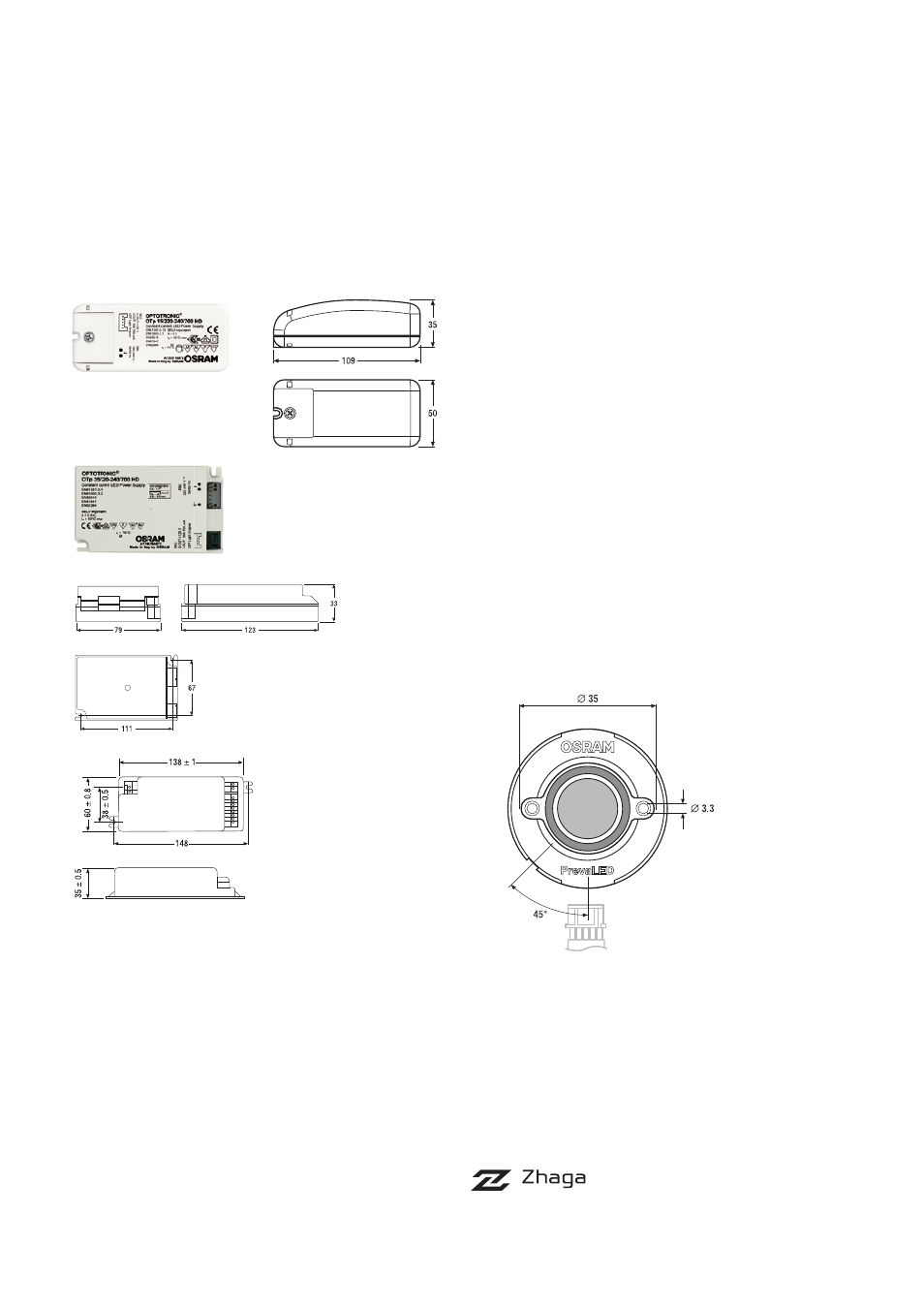

5.3. ECG dimensions

Detailed mechanical drawings and 3D fi les are available

at our website.

• The housing material of these devices (OTp 15/35/45)

is PBT and complies with UL 94 V-0.

• For input wiring on the network side, the housing

provides push-in terminals.

• It is recommended to use screws with washers when

attaching the ECGs to the luminaire.

5.4. LED module attachment

PrevaLED

®

Core Z2 modules are attached to a heat sink

with two M3 screws through the mounting holes within

the LED module. The mounting holes are reinforced with

metal. Only in this way can a suffi cient thermal contact be

ensured throughout the lifetime of the module, because

synthetics will, due to the infl uence of pressure and tem-

perature, give way after some time.

Depending on the thermal interface material and contact

surface conditions, the recommended screwing torque

can be between 0.4 and 0.6 Nm. A higher torque level

does not necessarily lead to signifi cantly better heat

transfer, but may lead to damage of the LED module.

The recommended counter sink diameter of the mounting

holes for good thermal performance should be 3.5 mm

max. A bigger counter sink can lead to mechanical defor-

mation of the PCB and thus to a deterioration of the

thermal connection to the heat sink. When mounting the

module with self-cutting screws, an additional torque

may be required to prepare the thread.

Due to a large number of possible combinations when

choosing thermal interface material, heat sinks and screws,

any chosen combination should be carefully checked and

tested in order to maximize the heat transfer between the

LED module and the heat sink. Optimal mounting can lead

to a lower operating temperature of the LED module and

thus to an improved performance of the system.

22

PrevaLED

®

Core Z2

All fi gures in mm

(except where noted otherwise)

OTp 15

(acc. to Zhaga: Driver category CS1)

All OTp 35 and OTp 45 types

(acc. to Zhaga: Driver category AM3)

OTp 60

All fi gures in mm

5.5. Zhaga – mechanical interface

In order to ensure the interchangeability of spot LED light

engines, Zhaga has defi ned maximum dimensions as well

as the screw positions for mounting the module. The

planarity of the luminaire side of the mounting surface, for

example, is not defi ned. For a fairly good heat transfer to

the heat sink, we recommend a planarity of < 0.1 mm and

a roughness of < 3.2 μm, as usually achieved by surfaces

with a milling fi nish.