Sidedraw instructions (continued), Wind ring installation, Discharge tube installation – Grain Systems Tanks PNEG-1000 User Manual

Page 86: Accessory instructions

13. Accessory Instructions

86

PNEG-1000 2.66" Commercial Tank Stiffener and Sidewall

Sidedraw Instructions (Continued)

2.66'' Sidedraw Instructions - 3 Post (Viewed from Inside of Bin)

These instructions for 90' diameter tanks and smaller. See PNEG-972 or PNEG-1343 for 105'

diameter tank sidedraw installation instructions.

Wind Ring Installation

Tanks that use wind rings require 2-3/4" diameter holes passing through the sidedraw chute; with the

center no less than 6" from either end and 4-3/8" from the sidewall. The wind ring must penetrate through

the chute and form a complete ring. Do not locate wind ring in 8" space at chute entrance. Field drill

stiffeners for wind ring attachment brackets (if required).

Discharge Tube Installation

1. Use the bottom two (2) holes in the last chute to locate discharge tube 28" below the 7

th

horizontal

seam. Refer to

for sidewall sheet hole

dimensions.

2. For proper water shed, install plate so upper body sheet overlaps the plate, as shown in

.

3. Use discharge tube assembly as a template, drill all holes 7/16" diameter.

4. Use two (2) beads of caulking to seal discharge plate to body sheets. Use 3/8" bolts and nuts

provided to bolt discharge assembly to body sheets. For all locations where the sidewall uses

3/8" x 1-1/2" long bolts, use the same bolt to install the discharge tube.

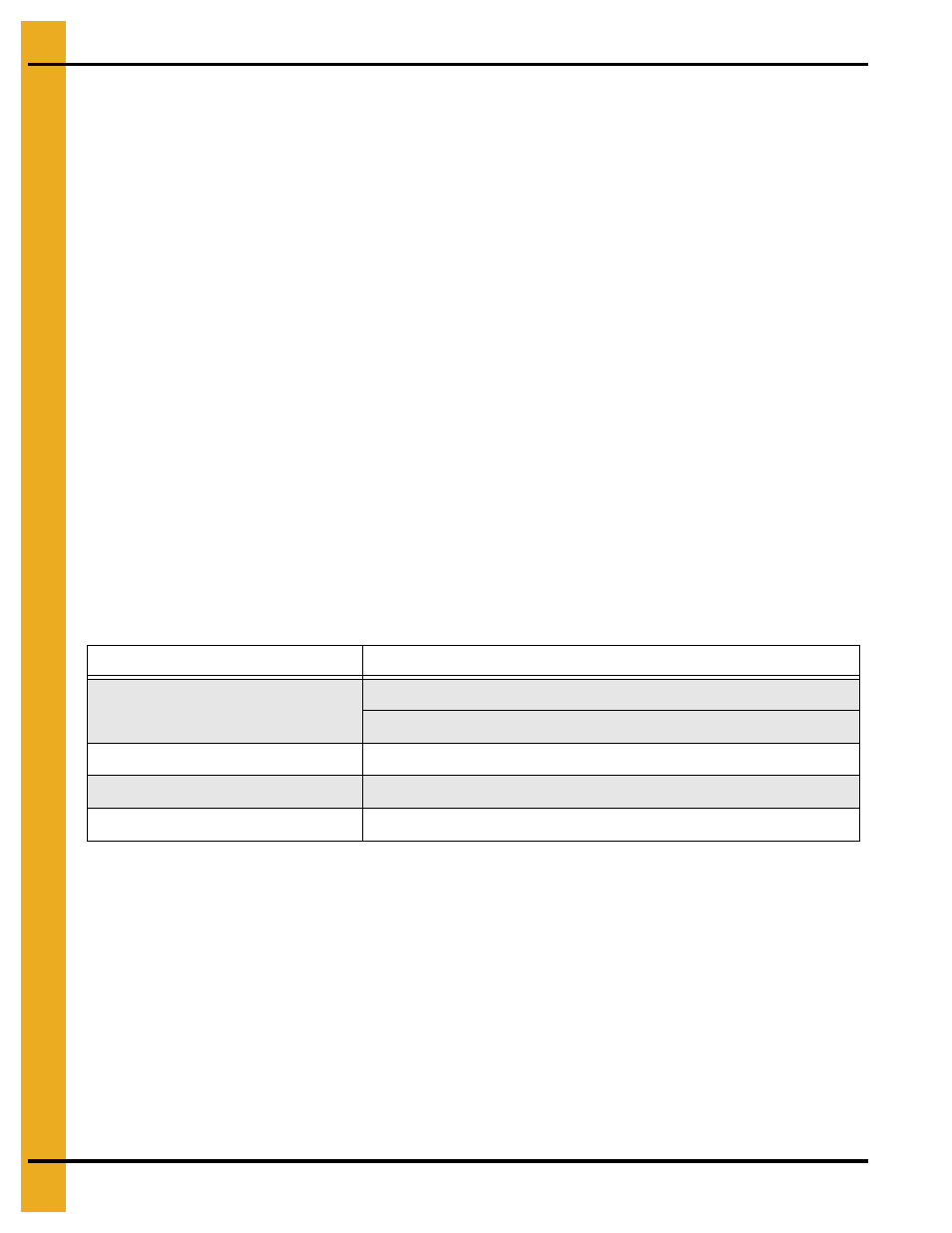

Number of Rings in Tank

Chute Location Horizontal Starting Location

All

1. Locate 1

st

chute in 2

nd

ring from top.

2. Top bolt holes in chute to be located on 2

nd

corrugation of body sheet.

11, 14, 17, 20, 23, 26, 29, 32 and 35

3. Center chute 75 inches (left to right) from 1

st

hole in 2

nd

body sheet.

10, 13, 16, 19, 22, 25, 28, 31, 34 and 37

4. Center chute 37.500 inches (left to right) from 1

st

hole in 2

nd

body sheet.

12, 15, 18, 21, 24, 27, 30, 33 and 36

5. Center chute over vertical seam.