Hardware requirements, Bolting requirements – Grain Systems Tanks PNEG-1000 User Manual

Page 20

6. Bolting Requirements

20

PNEG-1000 2.66" Commercial Tank Stiffener and Sidewall

* 105' diameter, 28 ring and taller tanks will utilize 7/16" x 2-1/2" bolts in the vertical seam.

3/8" x 2" bolts are provided for the overlap connection in the horizontal seam.

See the 105' tall tank series manual PNEG-972 if building 105' tanks 28 rings or taller.

*** A 3/8'' x 2'' bolt may be needed at first stiffener to sidewall bolt.

Before bolting sheets together, apply a single strip of caulking on both sides and 12" on both sides of top

edge. DO NOT CAULK BOTTOM EDGE.

1. When attaching a 13Q sheet to a 14Q sheet, use the 5/16" x 3/4" bin bolt on horizontal seam.

2. When attaching an 6Q sheet to a 8Q sheet, use the 3/8" x 1" bin bolt in the horizontal seam.

3. All base sheets are bolted to the base angle with 5/16" x 1-1/4" bin bolts (independent of

sidewall gauge).

Hardware Requirements

IMPORTANT:

Do not tighten bolts to exceed the torque specifications listed below.

Torque (ft. lbs.)

Bolt Size

Minimum

Maximum

5/16"-18

15

20

3/8"-16

35

42

7/16"-14

65

72

1/2"-13

95

105

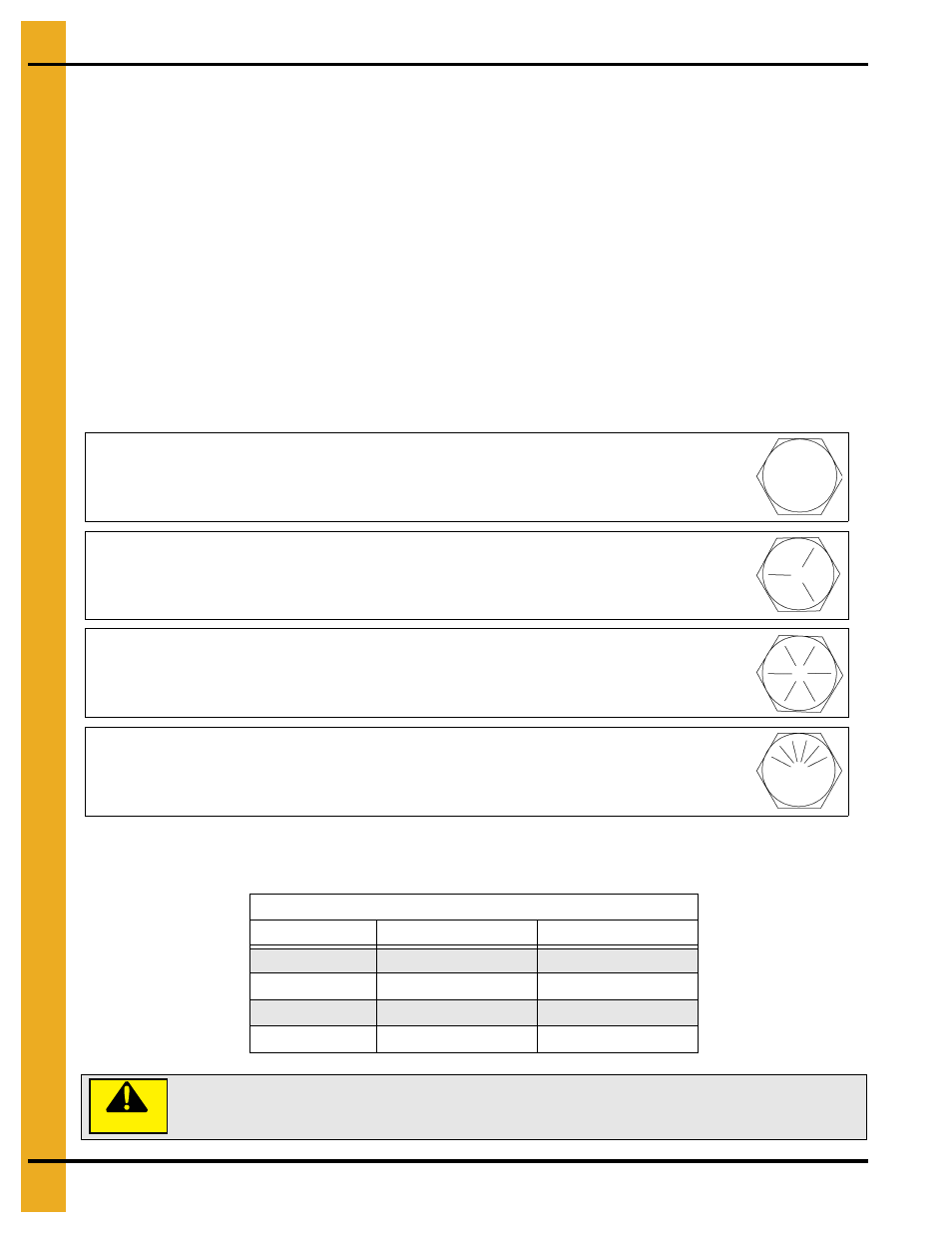

NOTE: Grade 2 bolts are designated with a plain head.

NOTE: Grade 5 bolts are designated by three (3) slash marks on the head.

NOTE: Grade 8 bolts are designated by six (6) slash marks on the head.

NOTE: Grade 8.2 bolts are designated by six (6) slash marks on the head in a

sunrise pattern.

Under no condition shall any other bolts be substituted for those supplied by

grain systems.

CAUTION