Veris Industries Badger 3000 SERIES Install User Manual

Page 3

3

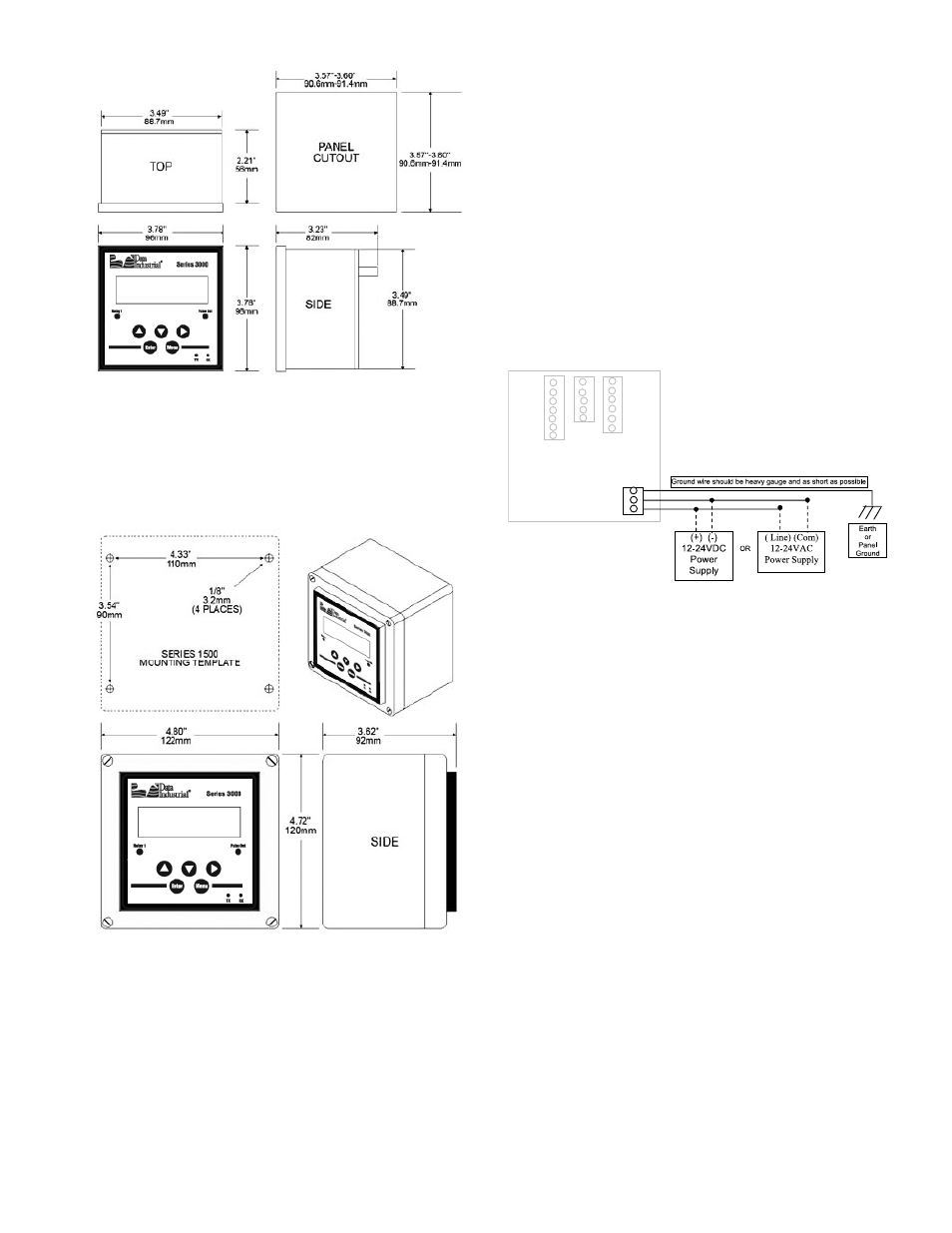

Wall Mount Installation

The Badger® Data Industrial® Model 3000 Wall Mount is

designed to mount onto a wall with four bolts or screws.

The mounting hole pattern and box dimensions for the

Model 3000 NEMA4 waII mount are shown in Figure 2.

ELECTRICAL INSTALLATION:

Power Supply Wiring

The Series 3000 requires 12-24 VDC/VAC to operate.

Check the specifications page for DC current draw, and

AC Volt-Amp requirements.

A fused circuit is always recommended.

Connect the positive of the power supply to the Series

3000 terminal marked (ACL/DC+), and connect the

negative of the power supply to the Series 3000 terminal

marked (ACC/DC-).

If a Badger Data Industrial plug-in power supply (Model

A1026, A-503) is being used connect the black-white wire

to the terminal marked (ACL/DC+) and the Black wire to

the terminal marked (ACC/DC-).

Figure 1: Panel Mounting Dimensions

Figure 2: Wall Mounting Dimensions

Earth

3

LV AC/DC(-) 2

LV AC/DC(+) 1

POWER

Figure 3: (Power Supply Wiring)

Flow Sensor Wiring

The Series 3000 Flow Sensor Inputs are extremely

versatile, designed to accept either two wire or three wire

pulse inputs (Badger Data Industrial 200 Series, 4000

Series), zero crossing sine wave inputs, or Analog inputs.

Although different rear panel terminals are used, all

parameters are set with the LCD/keypad interface. There

are no internal or external jumpers, switches, or potenti-

ometers to move or adjust.

Four types of Pulse Input Types are accommodated.

1. Pulse-DI: Used for all Badger Data Industrial Flow

Sensors.

Provides an internal Pull-Up resistor and uses “K” and

“Offset” values for calibration.

2. Pulse –K Factor:

Accepts non Zero Crossing inputs but provides no

internal pull-up, classical “K” ( Pulses/Gal) values for

calibration.

3. Pullup-K Factor:

Provides an internal Pull-Up resistor and uses

classical “K” ( Pulses/Gal) values for calibration.

4. Sine-K Factor:

Accepts Zero Crossing low voltage sourcing devices,

with classical “K” ( Pulses/Gal) calibration.

All the above wire the same as shown in Figure 4.

See Programming Flow Chart for required input con-

figuration.