Wheel and wheel valve, Drive axle wheel end service – Spicer TPCS (Tire Pressure Control System) Service Manual User Manual

Page 48

48

Wheel and Wheel Valve

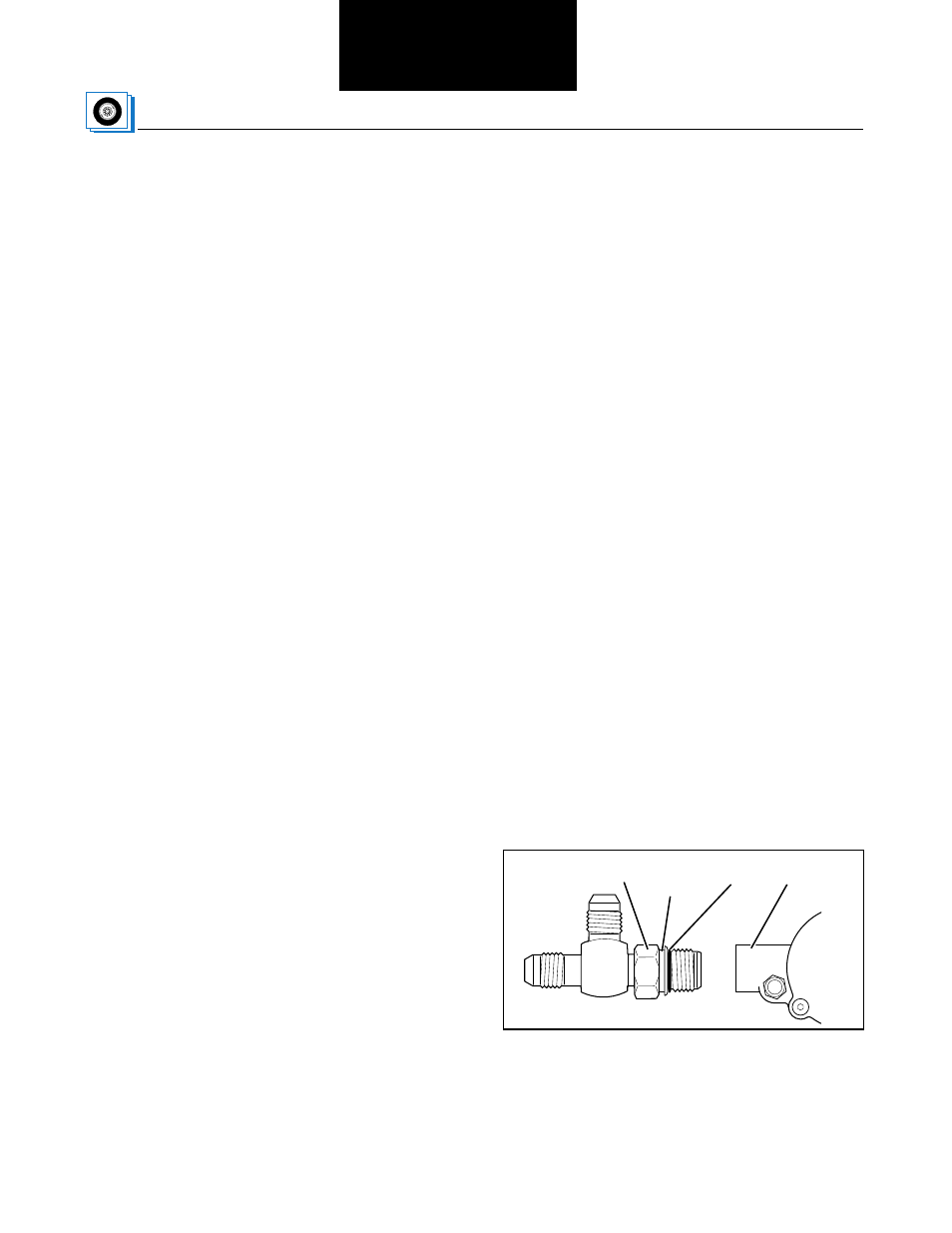

Figure 37 is a detailed view of the external air line

connections on a rear drive wheel.

Note: Perform the following steps with the wheels off

the ground to prevent the tires from losing bead seal.

Install drive axle wheel end pneumatics as follows:

1. Mount inside and outside drive wheels so that both

valve stems are positioned together and 180° from

the axle hub air fitting. Feed inner tire hose out

through wheel edge opening. Position hoses so

they will connect easily to wheel valve as shown in

Figure 38. Double check hose alignment.

2. Select two hub mounting studs that will position

wheel valve outlet port 180° from the axle hub air

fitting as shown in Figure 37. Remove the nuts

and lockwashers on the selected hub studs. Install

the wheel valve mounting bracket and replace the

hub lockwashers and nuts.

3. Set wheel valve within mounting bracket and fasten

to the wheel valve mounting bracket using

3

/

8

" x 1"

hex head bolts.

Note: Replace the air filter in wheel valve when the tire

or wheel valve is serviced. See Figure 37.

4. Prepare the wheel valve and hoses in the following

manner to minimize air loss from the tire when

reinstalling tire hoses.

A. Lubricate O-ring.

B. Secure lock nut against the O-ring washer.

C. Install the tee into the valve until the O-ring is

seated and the washer is against the face of the

valve.

D. Back off lock nut.

E. Turn tee clockwise to orient fitting – no more than

one turn.

F. Tighten lock nut 16–19 lbs. ft. (22–26 N•m).

Note: Work quickly to minimize air loss during

steps 5-8.

5. Remove valve stem core from inner tire, install hose

end on valve stem.

6. Remove valve stem core from outer tire, install hose

end on valve stem.

7. Install outer hose on run tee. Torque to 16–19 lbs. ft.

(22–26 N•m)

8. Install inner hose on branch tee. Torque to

16–19 lbs. ft. (22–26 N•m)

Figure 37 Run Tee

Locknut

O-ring

Washer

O-ring

Valve