Install drive axle inlet tube, Retightening sequence, Air seal installation – Spicer TPCS (Tire Pressure Control System) Service Manual User Manual

Page 44: Drive axle wheel end service

44

Install Drive Axle Inlet Tube

1. Install pipe end of

3

/

8

" male NPT to

3

/

8

" flareless tube

end, 45° elbow.

2. Position tube end toward opening of brake flange.

Feed drive axle inlet tube through brake flange hole

and insert into the tube end of the fitting. The tube

must bottom out in fitting

3. Manually screw nut onto fitting body until finger

tight.

4. Make reference mark on nut and tube and tighten nut

an additional 1

3

/

4

turns.

5. Loosen nut and inspect for proper preset.

Note: A ridge of metal has been raised above the tube

surface, to a height of at least 50% of the thickness of the

ferrule’s leading edge, completely around the tube. Avoid

rotating the ferrule.

Retightening Sequence

If the fitting body was used for ferrule pre-set, retighten

the nut to the same fitting body used earlier in the pre-set.

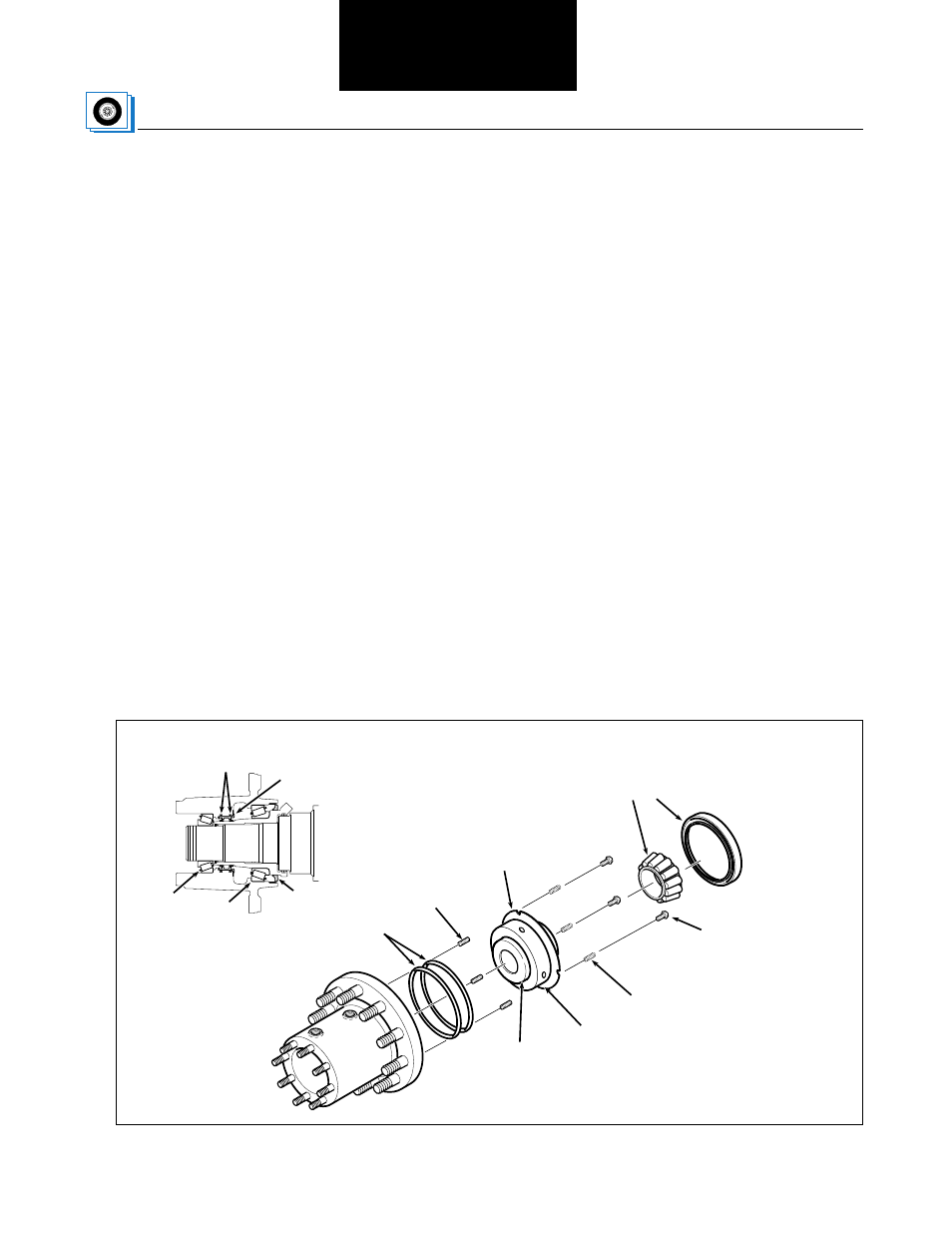

Air Seal Installation

1. Pre-lube the two hub inner O-rings and install in

wheel hub. (See Figure 33.)

2. Install three alignment pins in hub. Alignment pins

can be made of three

8

/

32

x 1

1

/

2

" screws with heads

removed.

3. Position the air seal assembly (with protective

guard) in hub and press into place until the flange

is seated against the hub.

• Remove pins.

• Apply removable thread locking compound to

the mounting bolt threads.

• Install the three

8

/

32

mounting bolts.

4. Pre-lube the inner bearing with the same lubricant

used in the axle sump. Place the inner bearing in

the wheel hub.

Figure 33 Wheel Hub Preparation for Installation

1. Install

O-ring Seals

3. Position Air

Seal Assembly with

Protective Guard

OIL

AIR

Hub Inner

O-ring Seals

Air

Seal

Oil

Bearing

New

Inner

Bearing

Outer

Bearing

2. Install Threaded

Alignment Pins

4. Remove

Threaded Pins

5. Apply Thread Locking

Compound and

Install Air Seal

Mounting Screws

6. Install Inner Bearing

and Unitized Hub Oil Seal

Protective

Guard

Air

Seal