Drive axle wheel end service – Spicer TPCS (Tire Pressure Control System) Service Manual User Manual

Page 46

46

4. Before installation, lubricate the outer bearing with

the same lubricant used in the axle sump.

Note: Lubricate only with clean axle lubricant of the

same type used in the axle sump. Do not pack the

bearings with grease before installation. Grease will

prevent the proper circulation of axle lubricant and may

cause wheel seal failure.

5. Install the outer bearing on the spindle.

6. Install the inner nut on the spindle and adjust as

follows:

• Torque the inner nut to 200 lb. ft.

(272 N•m) while rotating the hub.

• Loosen the inner nut one full turn.

• Re-torque to 50 lb. ft. (68 N•m) while rotating

hub.

• Back the nut off

1

/

4

turn.

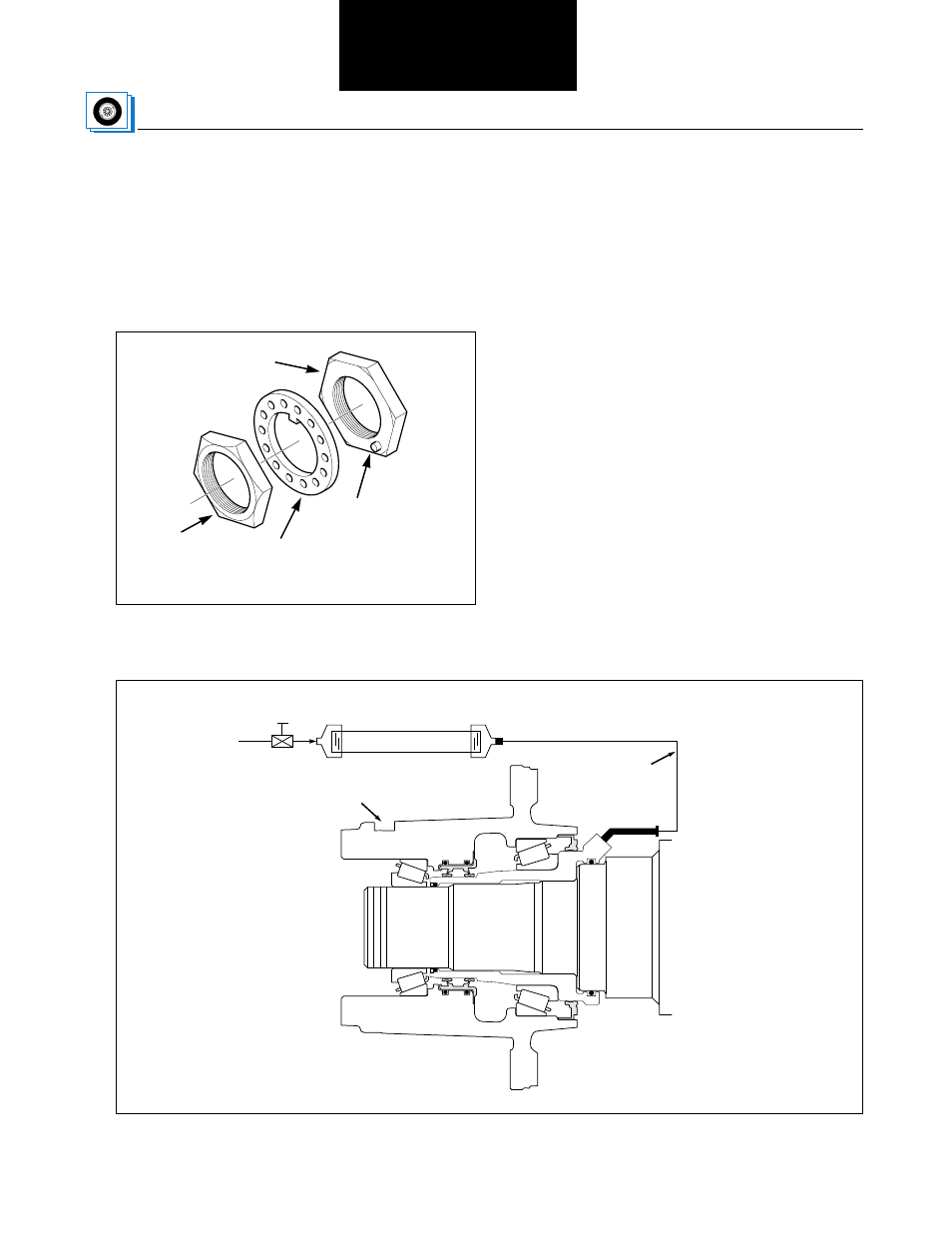

7. Install the spindle washer. See Figure 35.

• If the dowel pin and washer are not aligned,

remove washer, turn it over and reinstall. If

required,

loosen the inner nut just enough for

alignment.

Figure 35 Adjusting Nut Identification

Wheel Bearing

Adjusting Nut

(Inner)

Dowel

Pin

Spindle

Washer

Outer Nut

Figure 36 Sleeve O-Ring Leak Test

2" ID pipe, 12" long

Shop air

supply

Pressure Gauge

Reservoir

3/4" ID hose

2' long maximum

Valve

Air Port

- DSP40 Tandem Axle - Dare to Compare (2 pages)

- Ratio Flex Program Guide (46 pages)

- Italcardano Wing In A Box Product Line (3 pages)

- Vibration Diagnostics (1 page)

- Carrier-To-Housing Joint Leak (6 pages)

- Front Axle Shafts for the Jeep JK (2 pages)

- S400 Helical Gear Retrofit Kit Installation (2 pages)

- Electric Shift Unit (1 page)

- Approved Lubricant (16 pages)

- Tandem Drive Axles Pro-40 Single Reduction and Single Reduction with Differential Lock (102 pages)

- Kingpin Bushing and Seal Installation Instructions (2 pages)

- ROUND BEARING DRIVESHAFT COMPONENTS (11 pages)

- NEW REDESIGNED 40K TANDEM CARRIERS (6 pages)

- HAXL-PNI-34 (1 page)

- Tandem Drive Axles Service Manual S400 (34 pages)

- HAXL-PNI-31 (1 page)

- Single Drive Axles Service Manual: S170, S190, S590 (76 pages)

- PDU Cover & Outer Pinion Support Bearing for 46,000 LB (2 pages)

- 2007 Spicer Driveshafts Service Manual (32 pages)

- DRIVELINE COMPONENTS CATALOG SLIP YOKE ASSEMBLIES (28 pages)

- DualRange Tandem Axles (8 pages)

- S400 Redesigned Power Divider Parts for Service (2 pages)

- Wing Bearing Products U-Joint Identification Chart (1 page)

- 10 Series Driveshafts (86 pages)

- Driveline Components Catalog - Companion Flanges (24 pages)

- Gear & Pinion and Wheel Diff Case Kits Released for D_R170, D_R190 Models (3 pages)

- DST40-(P) (3 pages)

- 22719X, MODEL 44 POWER LOCK DISC AND PLATE KIT (1 page)

- 126155 (1 page)

- 2011 Spicer Bulletin 3; SERVICE_TECHNICAL INFORMATION (1 page)

- Drive Axles Service Manual Single Axles 2-Speed & Double Reduction (34 pages)

- X510-5DSD BILLS OF MATERIAL DODGE CATALOG CORRECTIONS (2 pages)

- Dana “I” Series (2 pages)

- Elimination of PDU Fill Plug On Tandem Drive Axles (2 pages)

- V Drive Components (1 page)

- RST41 (1 page)

- Torsionally Tuned-40 Tandem Drive Axles (2 pages)

- Drive Axles Illustrated Parts List DSS40, DDS40, RSS40, and RDS40 (28 pages)

- Single Drive Axles Service Manual: S140 Series (44 pages)

- DRIVELINE COMPONENTS CATALOG COUPLING SHAFTS - SPL and 10 Series (16 pages)

- Thick Flange Design Carriers (2 pages)

- 2002 Spicer Bulletin; SERVICE_TECHNICAL INFORMATION (1 page)

- Pre-applied Thread Adhesive Compound on Yoke End Nuts (6 pages)

- U-Tube Breather Assembly (2 pages)

- 130542 (1 page)