Sleeve installation, Drive axle wheel end service – Spicer TPCS (Tire Pressure Control System) Service Manual User Manual

Page 42

42

Drive

Axle Sleeve

Brake Spider

Spindle

A

B

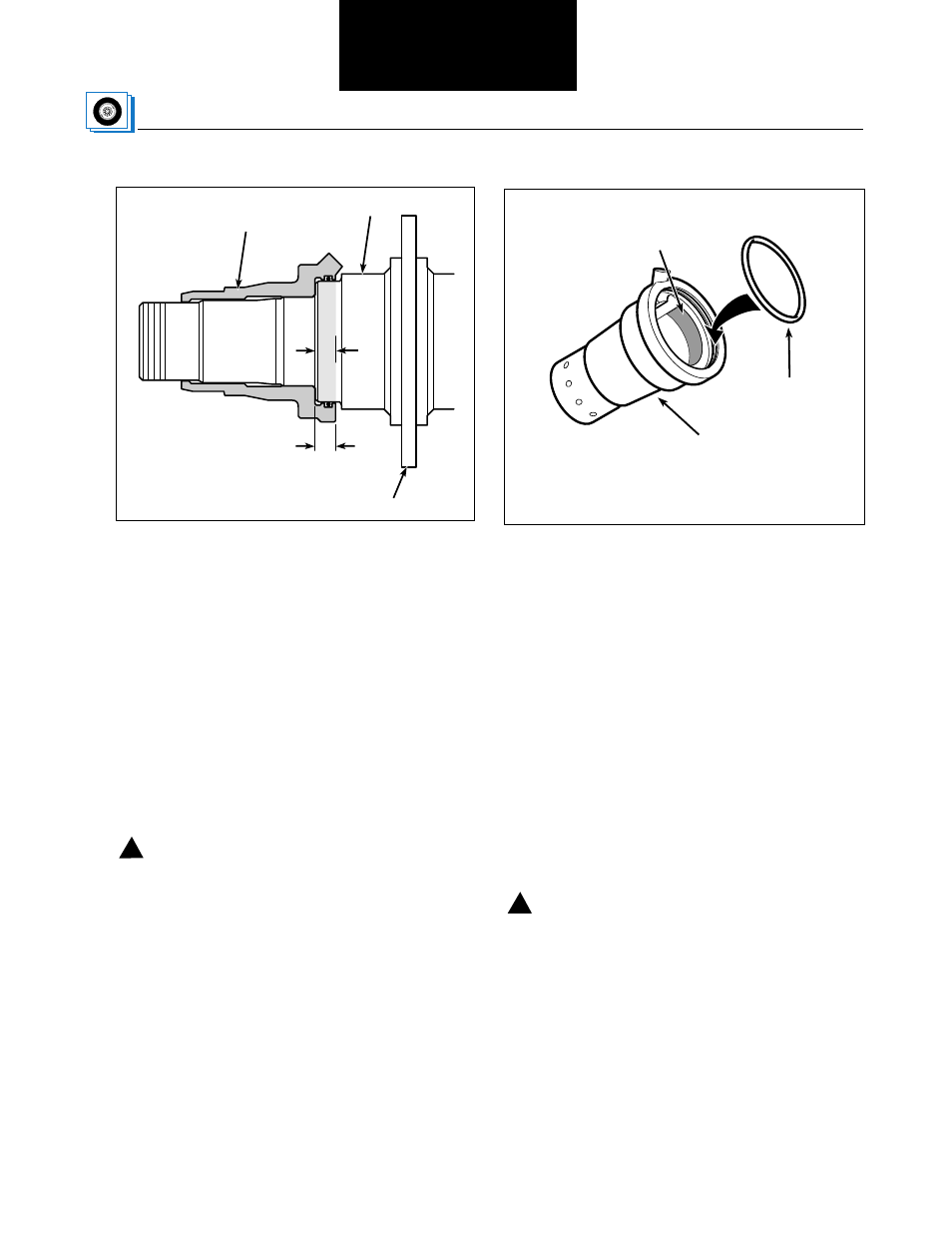

Figure 28 Spindle Sleeve Depth Measurement

Sleeve Installation

1. Measure the depth of the first step in spindle

sleeve to +/– .001". (See Figure 28, dimension “A”)

Measure out this distance on the axle spindle’s oil

seal area. (See Figure 28, dimension “B”.) Mark

this point on spindle.

2. Apply an anti-seizing compound to the sleeve as

shown. See Figure 29.

3. Apply lubricant to the sleeve inner O-ring and

install in groove in large diameter end of sleeve.

See Figure 30.

Caution: Do not allow anti-seize to get into air

passages.

4. Apply grease to the inboard sealing surface of the

axle spindle. See Figure 30.

5. Position the sleeve on the axle spindle, making

sure to align the input air port of the sleeve with

the Tire Pressure Control System air line access

hole on the brake flange and spider. See Figure 32.

6. Attach the sleeve installation fixture to the brake

spider as follows:

• Install base plate to four threaded rods and

against welded locating nuts. Secure with flat

washers and nuts. See Figure 32.

!

Drive Axle

Sleeve

Sleeve

Inner O-ring

Apply

Anti-seize

Figure 29 Sleeve Inner O-Ring Installation

!

• Align four threaded rods with holes in brake

spider and install. See Figure 32. Secure with

flat washers and nuts.

7. Press the sleeve onto the axle spindle as follows:

See Figure 32.

• Install mounting cup on spindle and align with

end of sleeve.

• Hold the bottle jack against the base plate and

pump until jack head engages the other end of

the installation tube.

• Extend jack until sleeve is bottomed on axle

spindle.

Caution: Be sure that the inside end of spindle

sleeve is installed far enough to meet mark put on

spindle in step 1.

• Retract bottle jack and remove sleeve installa-

tion fixture.

8. Lubricate and install O-ring and backup ring into

drive axle sleeve as shown in Figure 31.

Note: Position O-ring and backup ring on spindle. Use

outer bearing and hand pressure to press them into

position.