Oil seal installation, Wheel hub installation, Oil seal installation wheel hub installation – Spicer TPCS (Tire Pressure Control System) Service Manual User Manual

Page 45: Drive axle wheel end service

45

Caution: Use care when applying thin coat of

Aeroshell. Make sure not to plug air passages

with lubricant.

2. While insuring that the spindle end will pass

through the air seal protective guard, slide hub into

position on the spindle and sleeve with one push.

• As the hub is installed, the air seal protective

guard will be pushed out. Remove the air seal

protective guard.

Caution: Do not pull the hub in and out or rock to

install. This will cause damage to the air seal.

3. If the hub does not install with the initial push,

remove hub from spindle and reposition the air

seal protective guard from the inner bearing side

only. Repeat step 2 for installation.

Note: During installation it may be necessary to use a

screwdriver to align inner bearing with the drive

sleeve bearing journal. Be careful not to damage

oil seal.

Oil Seal Installation

Using the following tools, install the oil seal in the

wheel hub. (See Figure 32.)

• Seal Plate

• Bearing Centering Tool

• Handle Assembly

Caution: Do not hammer directly on the seal!

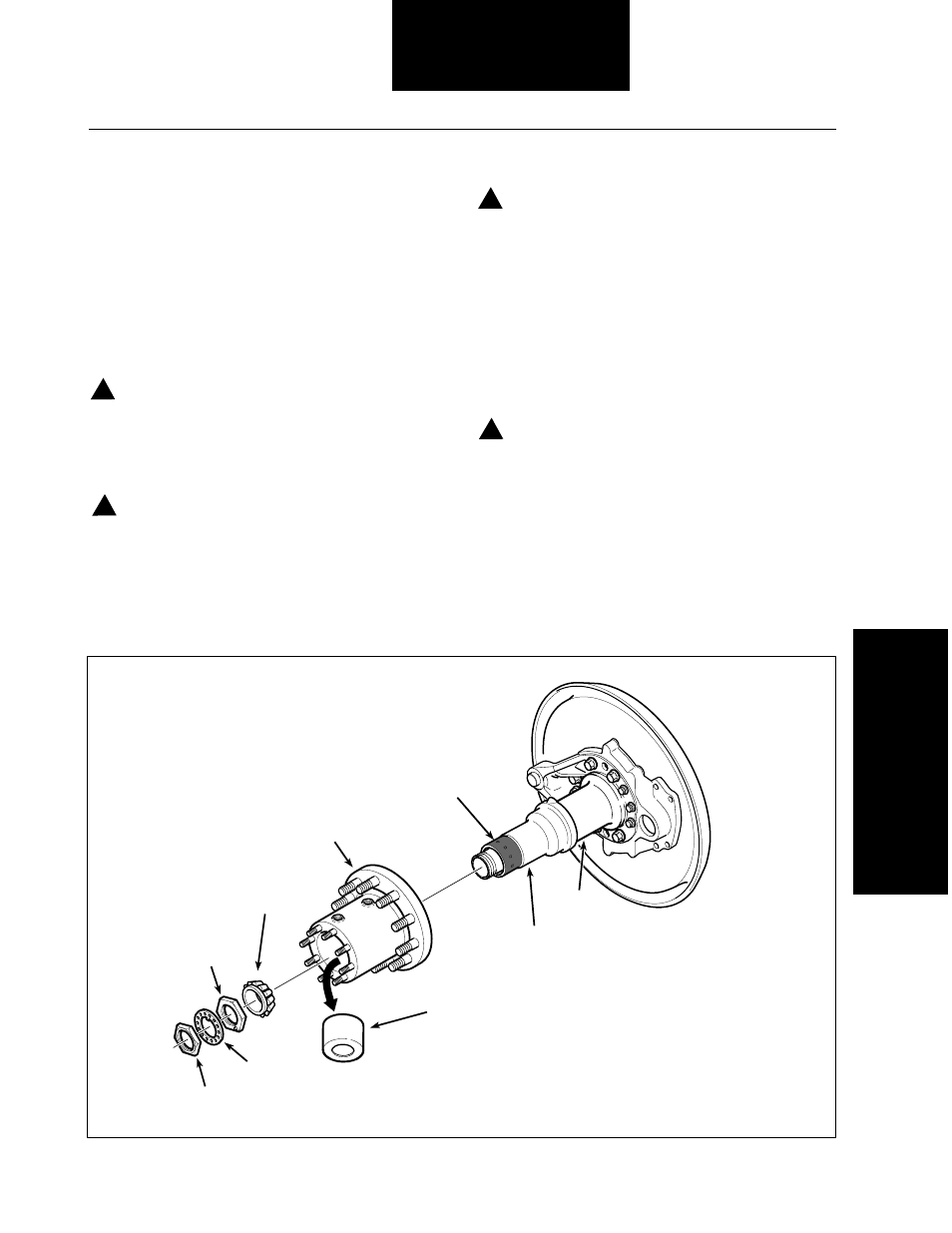

Wheel Hub Installation

See Figure 33

Caution: Make sure protective guard is installed

in air seal before hub is installed on drive axle

sleeve.

1. Apply thin coat of Shell

®

Aeroshell GR22 or

equivalent to the portion of the sleeve where the air

seal runs.

Air Seal, Wheel Hub and

Oil Seal Installation

!

!

!

!

Figure 34 Wheel Hub Installation

Drive Axle

Sleeve

Spindle

Outer

Bearing

Inner

Jam Nut

Spindle

Washer

Outer

Jam Nut

Wheel Hub

with Air Seal

and Protective

Guard Installed

OIL

AIR

Air Seal

Protective Guard

(Remove After

Hub is in Place

on Sleeve)

Apply thin coat of

Shell Aerolube GR22

to this area