M&C TechGroup CLF-5_W Operator's manual User Manual

Page 2

Gas sampling and gas conditioning technology

5-1.10.7-ME

M&C TechGroup Germany GmbH

z Rehhecke 79 z 40885 Ratingen z Germany z Tel.: (0)2102/935-0 z Fax: (0)2102/935-111 z www.mc-techgroup.com

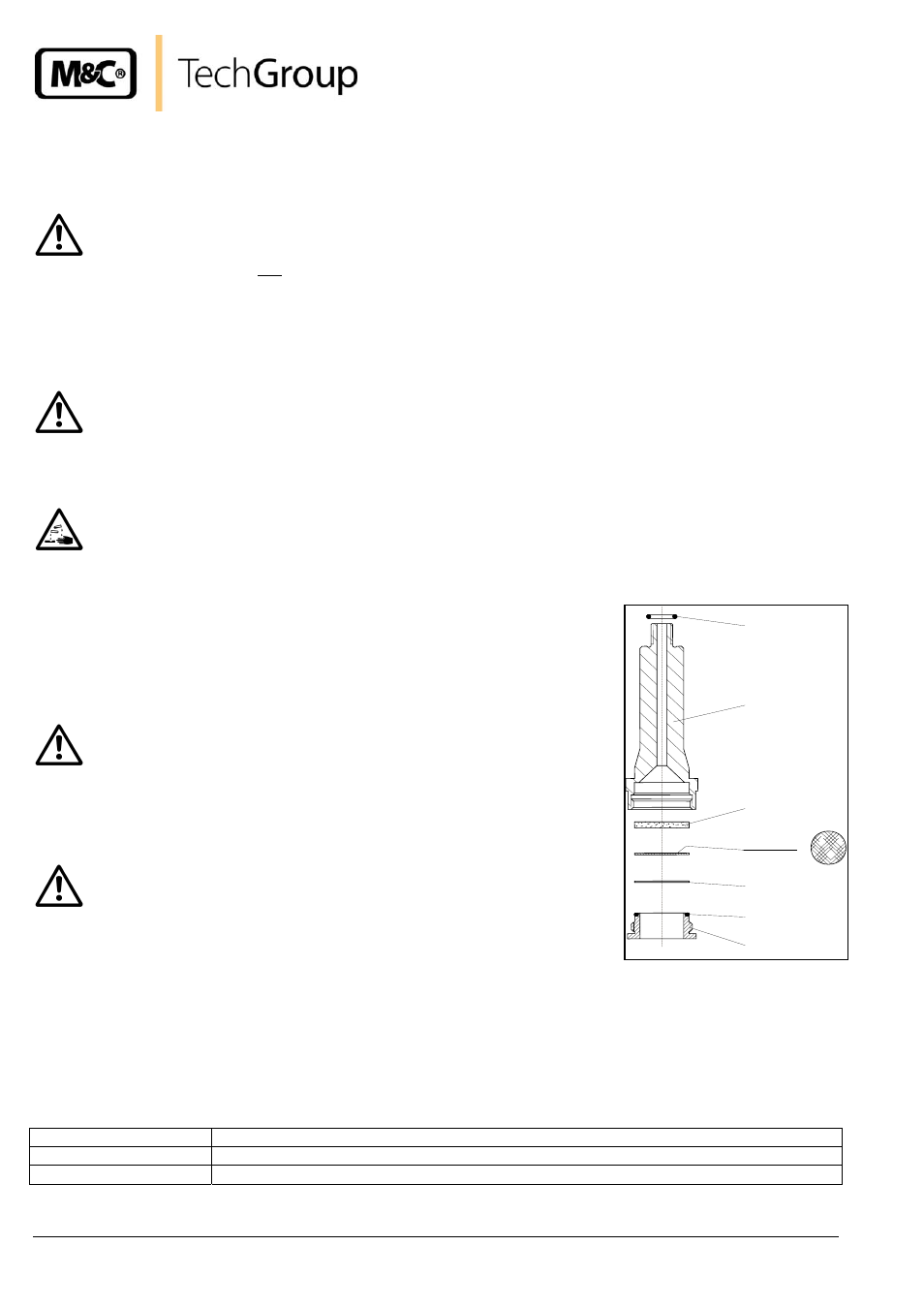

Glass frit

Filter element holder

Surface

Plain washer

Press screw

Part No.:90F3515

Part No.:90F3500

Part No.:90F3520

Part No.:90F3505

Part No.:90F3525

Part No.:90F3510

Diaphragm filter

Part No.:91E4010

O-ring

O-ring

Connection of the sample line

The connections of the sample lines are marked by red arrows.

When using the upper entry

d on the head of the filter for the measuring gas inlet resp. outlet, the

function of the filter is not guarantied (see flow direction in the filter).

Mounting Instruction Water-Stop CLF-5/W

The following instruction shows the mounting of the PTFE diaphragm into the liquid particle filter type CLF-5/W.

The system must be checked directly when flow is interrupted. A water breakthrough can damage

the analyser(s). Pay attention to absolutely cleanness when mounting the diaphragm.

Contaminations affect the function of the Water-Stop.

The maximum working pressure is 2bar absolute and the maximum temperature is +80°C.

Aggressive condensate possible. Wear safety glasses and protective clothes!

The following steps have to be carried out:

• Unscrew the filter glass counter-clockwise.

• Unscrew the filter element holder d.

•

Unlock the press screw

h and dismantle the glass frit c with the

diaphragm filter

e and the flat ring disc f.

When re-fitting the glass frit be sure that the smooth side is opposite

to the filter element holder.

• Fit the diaphragm filter with the weft side towards the glass frit.

•

Place the flat ring disc on the diaphragm filter.

When changing the O-ring of the press screw do not roll up. In case

other materials for the O-ring have been used due to technical

reasons, this is noted on the type plate. Please pay attention to this

and specify when ordering replacement parts.

Screw the press screw by hand into the filter element holder up to the diaphragm filter.

The assembly of the fluid particle filter happens in the opposite way.

Recommended spare parts

Wear, tear and replacement part requirements depend on specific operating conditions.

Part No.

Description

90 F 3530

Spare part set consisting of: glass frit

c, diaphragm filter e, flat ring disc f and O-ring g

90 F 3535

Spare part set consisting of: diaphragm filter

e, flat ring disc f