Technical data – M&C TechGroup PMA 100 Data sheet User Manual

Page 3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

13.6

Technical specifications and illustrations are without

obligation, subject to modifications. 05.97/01.07

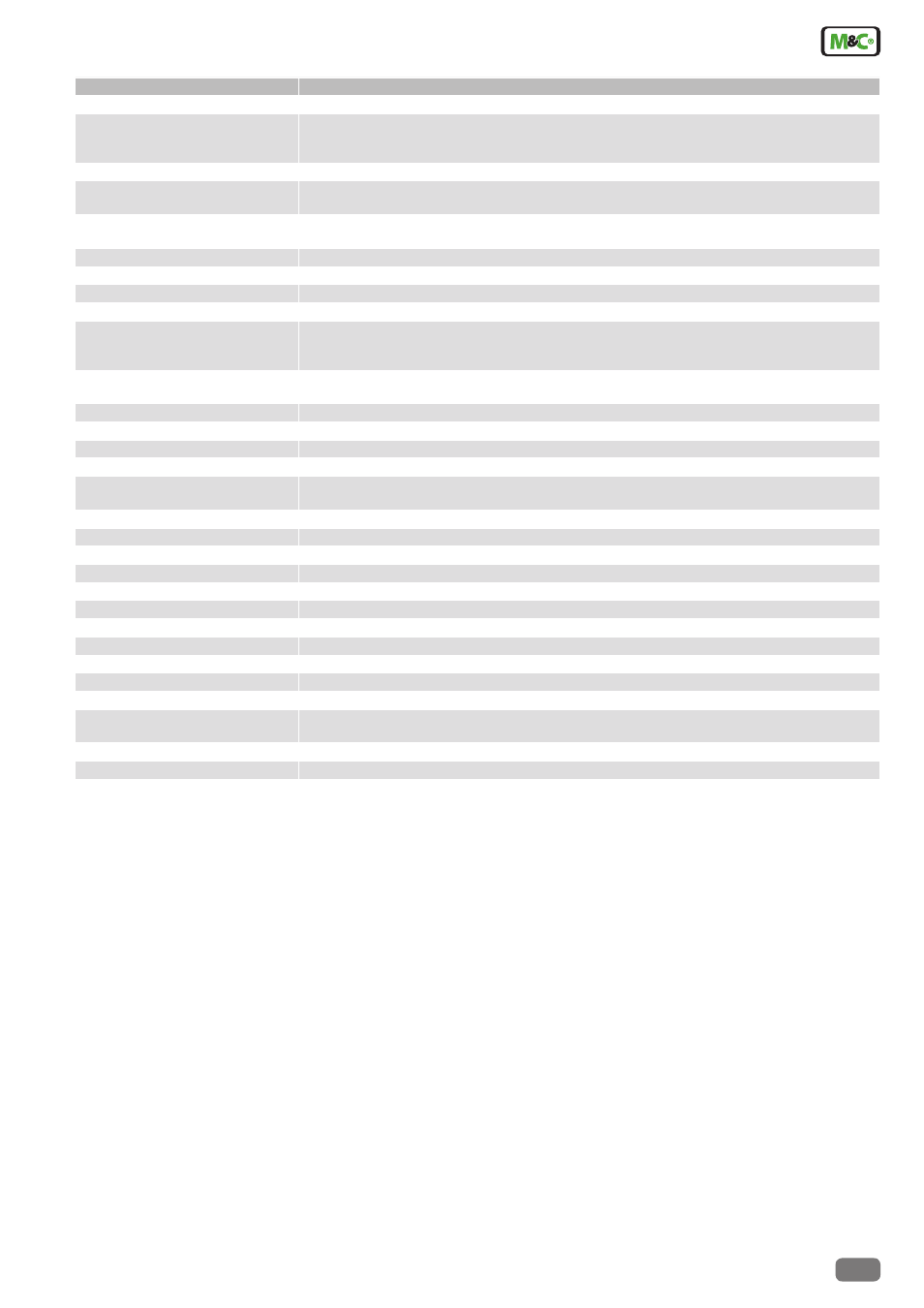

Technical Data

W A R N I N G ! I M P O R T A N T !

An external fine filter must always be used at the gas inlet of the analyser. Depending on the

composition of the sample gas, it may be necessary to use a sample conditioning system.

Without precautions, the analyser is only suitable for measuring of non-hazardous gases or

gasmixtures in non-hazardous areas.

Version PMA 100 microprocessor based oxygen analyser in 19"-housing

Part No.

03A3000 : PMA 100 power supply 230V 50Hz, 4-20mA; 03A3000a = 115V 60Hz

Measuring ranges

4 linear measuring ranges free selectable, lowest span 1%,

basis selection* 0-1, 0-10, 0-25 and 0-100 vol. O

2

.

manual, automatic or remote range control and range indication is possible

Indication

two line 16-sign LCD display, resolution 0,01vol.% O

2

, continuous O

2

indication and call off

Text illustration optional in

English, French or German

O

2

-transducer temperature, mA-signal, measuring range, time, date, failure-/alarm information,

process pressure

Output signals

selection: isolated 0-20, 2-20, 4-20*, 4-20,5mA for the selected range, max. load 500Ω.

interface RS232 type AK-communication protocol - bi-directional, option interface RS485 type

Relay outputs free configurable

4 potential free relay contacts NO, contact rating max. 48V

DC

, 500mA, 15W

Binary outputs

drive of 3 external solenoid valves for calibration, 3x 24V

DC

, max. 400mA

Binary inputs free configurable

potential free, 4x 12-24V

DC

, max. 20mA or internal supply voltage 12 V

DC

Flow alarm

thermo-conductive sensor, mounted downstream O

2

-measuring cell

Status alarm

for min. flow alarm, O

2

-transducer temperature < 50 °C, central processing unit failure, pressure sensor: LED indica-

tion and potential free contact output, NO, max. 48V

DC

, 500mA, 15W

and mA-output indication - example 22mA

Alarm contact

for exceed/remain measuring range, truncate calibration, external alarm, alternatively oxygen level alarms: LED

indication and potential free contact output, NO, max. 48V

DC

, 500mA, 15W

Response time for 90% FSD

< 3 seconds at 60 Nl/hr air

Accuracy after calibration

deviation ± 1% of 2-100% span, ± 2% of 1% span

Reproducibility

deviation < 1% of span

Influence of ambient temperature

no influence up to 50 °C

Influence of barometric- or

process pressure

no influence within the range of 0,6 up to 1,6bar abs. with integrated pressure compensation

Influence of sample gas flow

variation in gas flow between 0-60 Nl/hr air will cause a difference of < 0,1 vol.% O

2

Sample gas inlet pressure

0,01 up to 0,6 bar g, (PMA 100 requires positive pressure for adequate flow rate, no pump inside)

Sample gas outlet pressure

recommendation: discharge freely into atmosphere; however max. 0,6 to 1,6 bar abs.

Flow rate of sample gas

25-60 Nl/hr air

Temperature of sample gas

-10 °C up to +50 °C dry gas

O

2

-transducer temperature

fixed at +55 °C

Ambient temperature

-10 °C up to +50 °C

Storage temperature

-20 °C up to +60 °C, relative humidity 0-90% RH

Power supply

internal power unit for 230V

AC

standard or 115V

AC

available (a) +/- 10%, 40-60Hz, 35VA

Electrical connections

mains supply: 3-pole chassis plug with 2 m cable; signals: 4x Sub-D plug

Materials in contact with sample gas

Platinum, Epoxy resin, glass, FPM, Stainless Steel 316Ti, PTFE, PVDF

Sample gas connection

1/8" NPT internal thread*, option with tube connector DN 4/6 /PVDF available,

Part No. 05V1045

Protection / electrical standard

IP 40 EN 60529 / EN 61010

Housing / front colour

19 inch rack mounting with front handles / grey RAL 7032

Dimension / weight

height 4U, width 84HP, depth 350 mm + approx. 60 mm installation space / approx. 11 kg

*standard