M&C TechGroup CG Series Data sheet User Manual

Page 2

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

12.1

Technical specifications and illustrations are without

obligation, subject to modifications. 07.00/12.06

TechnicalData

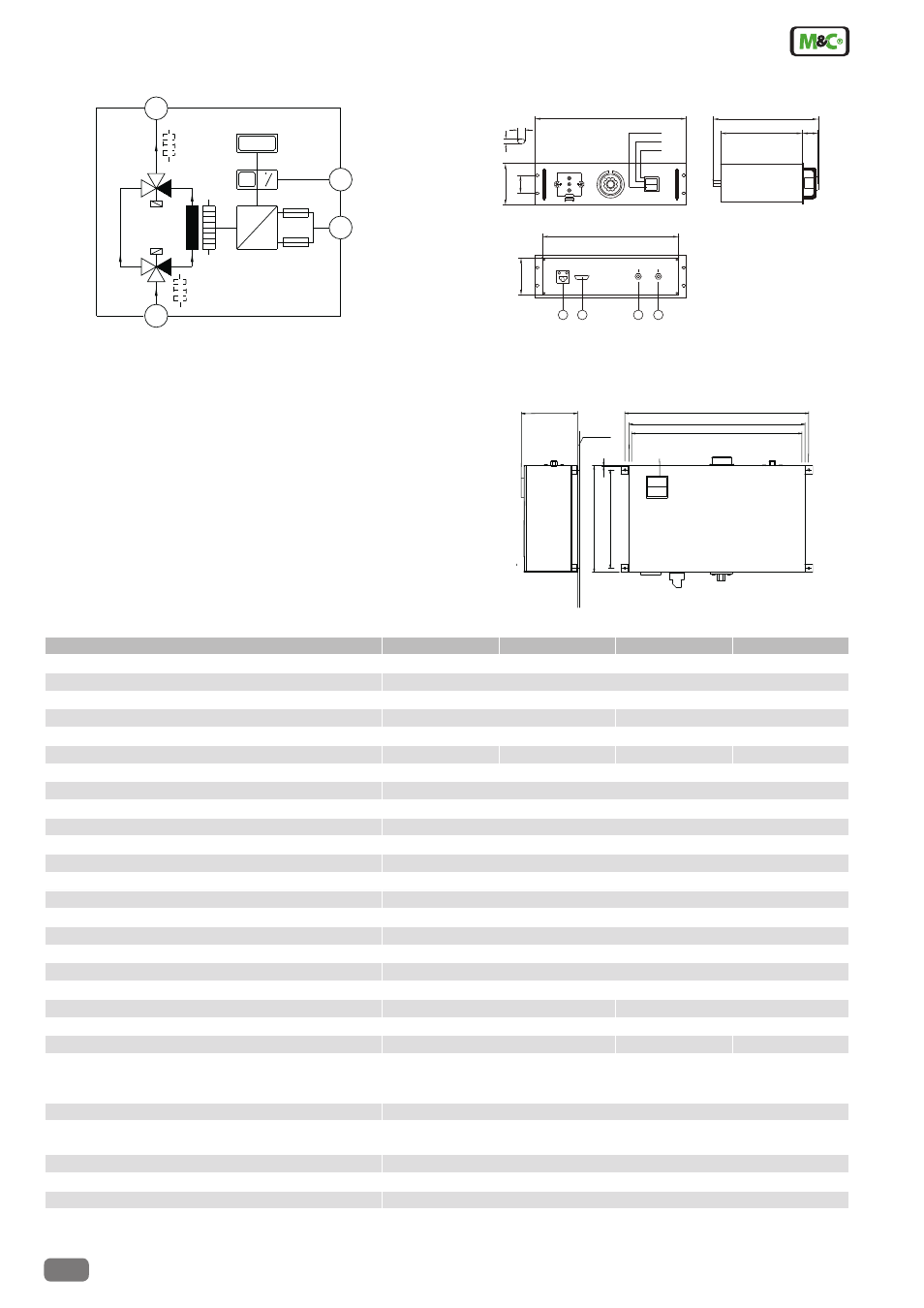

DimensionsCG-2,CG-2M,19”-rack

housingunheatedgasinletandoutlet

FunctionaldiagramtypeCG-2M

Versions CG-2, CG-2H-W without Y1/2, Version CG-2MH-W without Y2

Dimensions in mm

132.5

7

10

325

D

C

A

B

G1/4"i

view from the backside

B1.0

B1.2

B1.1

40

260

57

483

129

435

400

400

(3HE)

(84TE)

B 1.0

B 1.1

B 1.2

350

350

C¡

E1

Y1

Y2

B

A

C

D

E2

E2

A

Status alarm temperature

B

Power supply

B1.0 Temperature control

B1.1 Temperature alarm

B1.2 Temperature display

C

Sample gas inlet in

D

Sample gas outlet

E1 Tube furnace

Y1 3/2-way solenoid valve (only in version CG-2M, CG-2MH-W)

Y2 3/2-way solenoid valve (only in version CG-2M)

E2 Heating sample gas inlet, outlet and Y1 (only in version

CG-2MH-W) or heating sample gas inlet and outlet (only in

version CG-2H-W)

265

2

437

423

Temp. controller

Power

External

control/

Alarm

Sample gas outlet

DN 4/6*

DN4/6*

Sample gas in

Cabinet

mounting plate

Sample gas inlet

DN4/6

converted

3 5 0.0

3 5 0.0

457

245

145

by customers

Dimensions CG-2H-W, CG-2MH-W, wall mount-

inghousing,heatedgasinletandoutlet

GasConverterSeriesCG®

VersionCG-2

VersionCG-2M

VersionCG-2H-W

VersionCG-2MH-W

Part No. without catalyst cartridge

50A1600 (a)

50A1500 (a)

50A1900 (a)

50A1920 (a)

Part No. catalyst cartridge type C, carbon-molybdenum

95A9003

Part No. catalyst cartridge type SS, metal filling

95A9004

Gas inlet and outlet non heated (cold) or heated (hot)

non heated

heated

Housing

19" rack mounting 3U depth 350 mm

wall mounting housing

Bypass solenoid valves

no

2x

no

1x

Temperature of sample gas

max. +80 °C, dew point “dry”

max. +250 °C, dew point<160 °C

Temperature range, adjustable

max. 680 °C

Gas flow rate

max. 90 Nl/hr

Operating pressure

max. 2 bar abs.

Warm-up time

approx. 30 min.

Operating temperature at N0

2

/ NO converter with type C

350 °C

Operating temperature at N0

2

/ NO converter with type SS

660 °C

Conversion N0

2

/ N0

Efficiency >95 % with new catalyst

Live of catalyst N0

2

/ N0

to renew approx. every 6 months as preventive measure

Differential pressure

<20 mbar

Ambient temperature

+10 °C to +50 °C

Storage temperature

-25 °C to +65 °C

Relative humidity

<80 %

Sample gas connections

PVDF fitting G1/4” i DIN 228/1

ø6 mm tube connector, SS316Ti*

Power supply

230V 48-62Hz or (a) 115V 48-62Hz

Power consumption

520W

620W

940W

Electrical connection

Main power plug connector incl. two fine fuse 5 x 20 mm,

230V: 6,3A, 115V: 10A, 2 m cable and shock-proof plug.

Alarm-/control signals 9-pin sub D connector

Status signals for temperature

NO contact-potential free, contact rating max. 24V, 1A

Materials of sample contacting parts

Stainless steel SS 316Ti, PTFE, FPM

Stainless steel SS 316Ti,

alu hardcoated, FPM

Degree of protection

IP 20 EN60529

Weight

approx. 6 kg

Electrical equipment standard

EN 61010, EN 60519-1

Optionfor19”-rackhousing

Wall mounting bracket, 3U-84HP, Part No.: 50A3000

* Standard ø 6 mm, for ø 1/4" – please indicate with order. Other executions on request