Technical data, Options – M&C TechGroup CSS-V2 Data sheet User Manual

Page 3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.1

Technical specifications and illustrations are without

obligation, subject to modifications. 11.08/11.12

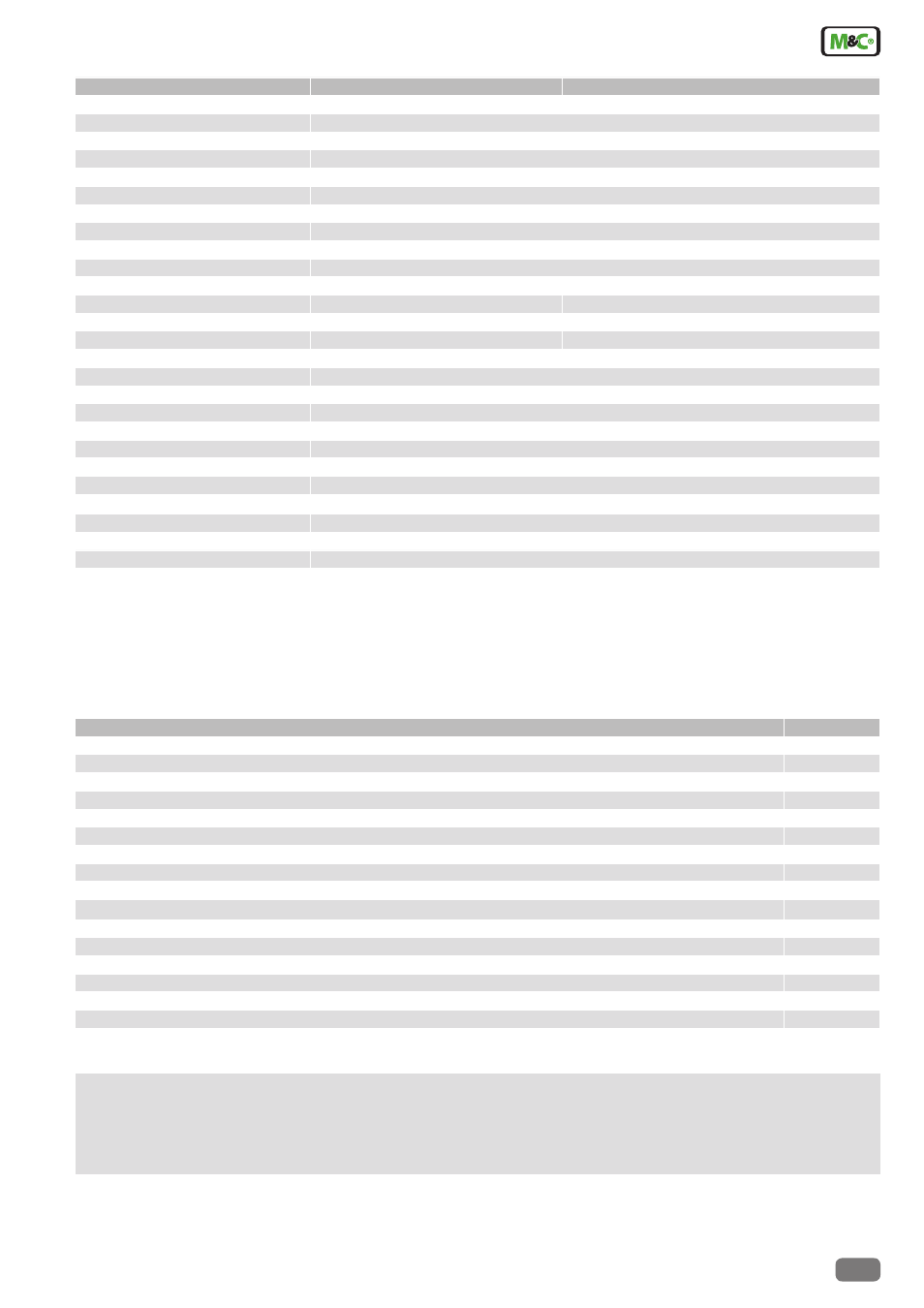

Technical Data

Gas Conditioning Unit series CSS

®

version CSS-V1

version CSS-V2

Part No. for 230V 50Hz version

01G6010

01G6020

Extra charge 115V/50-60Hz

01G6160

Sample outlet dew point

range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability

at constant conditions < ±0,1 °C

Sample inlet temperature

**max. 180 °C

Sample inlet dew point

**max.+80 °C

Gas flow rate

**max. 250 Nl/hr

**max. 2 x 150 Nl/hr

Ambient temperature

**+5 °C up to +40 °C

Storage temperature

-25 °C up to +65 °C

Pressure

0,7 bar up to 1,4 bar abs.

Total cooling capacity **

max. 144 kJ/hr

Number of gas inlets

1

2

Number of gas outlets

1

2

Condensate outlet

1

2

Medium connections

tube connection 4/6 mm

Material of sample contacting parts

PVDF, Novoprene

®

,FPM, PVC, PPH, PTFE

Ready for operation

approx. 10 min.

Power supply

230V 50-60Hz ±10% or 115V 50-60Hz ±10% (115V/50Hz not with option sample pump)

Power consumption

max. 220VA + max. 300VA for the sample gas pump

Fuse protection

4A t, 5x 20 mm

Electrical connection

Cold appliance plug with 2 m of cable

Case protection

IP20 EN 60529

Sheet steel housing, execution

sheet steel case for 19"- or wall mounting, lacquered RAL 7032

Equipment dimensions

267,5 mm x 483 mm x 301,5 mm (H x W x D)

Electrical equipment standard

EN61010

Weight

approx. 22 kg

PVDF = Polyvinylidenfluoride

PVC

= Polyvinylchloride

FPM

= Fluor caoutchouc = Viton

®

PPH

= Polypropylene hard

PTFE = Polytetraflourethylene

**

Maximum values in technical data must be rated in consideration of total cooling power at 25 °C and an outlet dew point of +5°C.

Description

Part No.

Extra charge for heat exchanger ECM-1 out of glass

93K0140

Extra charge for heat exchanger ECM-1 out of stainless steel SS316Ti

93K0160

Extra charge for heat exchanger ECM-1 out of PVDF

93K0170

Extra charge for heat exchanger ECM-2 out of glass

97K0100

Extra charge for heat exchanger ECM-2 out of stainless steel SS316Ti

97K0115

Extra charge for heat exchanger ECM-2 out of PVDF

97K0110

Extra charge for mounting the sample gas pump N3KPE (additionally electronic controller 01G6150 necessary)

01G6125

Extra charge for mounting the sample gas pump N5KPE (additionally electronic controller 01G6150 necessary)

01G6130

Extra charge for mounting the sample gas pump N9KPE (additionally electronic controller 01G6150 necessary)

01G6135

Extra charge for mounting a sample gas filter FPF-2-0,3GF with integrated liquid alarm sensor

01G6120

Extra charge for mounting a flow meter FM40 7-70Nl/hr

09F4000

Extra charge for mounting a flow meter FM40 15-150Nl/hr

09F4005

Extra charge for mounting a flow meter FM40 25-250Nl/hr

09F4010

Extra charge for mounting a flow alarm sensor FA-20mo

02E3500

Extra charge for mounting a peristaltic pump SR25.2 for condensate removal, completely flexible tubed

01G6140

Extra charge for mounting an electronic controller for max. 2 liquid alarm sensors and max. 2 flow alarm sensors

01G6150

Options

Orderexample:

1x 01G6010 + 1x 93K0140 + 1x 01G6125 + 1x 01G6120 + 1x 09F4010 + 1x 02E3500 + 1x 01G6140 + 1x 01G6150 = CSS-V1 , 230V, with heat

exchanger out of glass, built-in sample gas pump N3KPE, sample gas filter FPF-2-0,3GF with integrated liquid alarm sensor, flowmeter FM40

25-250Nl/h and flow alarm sensor FA-20mo, peristaltic pump SR25.2 for condensate removal and electronic controller for liquid and flow

alarm sensor.