Troubleshooting, Boiler manual – Weil-McLain 550-141-826/1201 User Manual

Page 7

HOMEOWNER and SERVICE TECHNICIAN — read and follow completely.

Troubleshooting

Homeowners — The problems and corrections below represent common situations that can occur. There may be

others not listed below. It is important always to contact a qualified service technician if you have any questions

about the operation of your boiler or system.

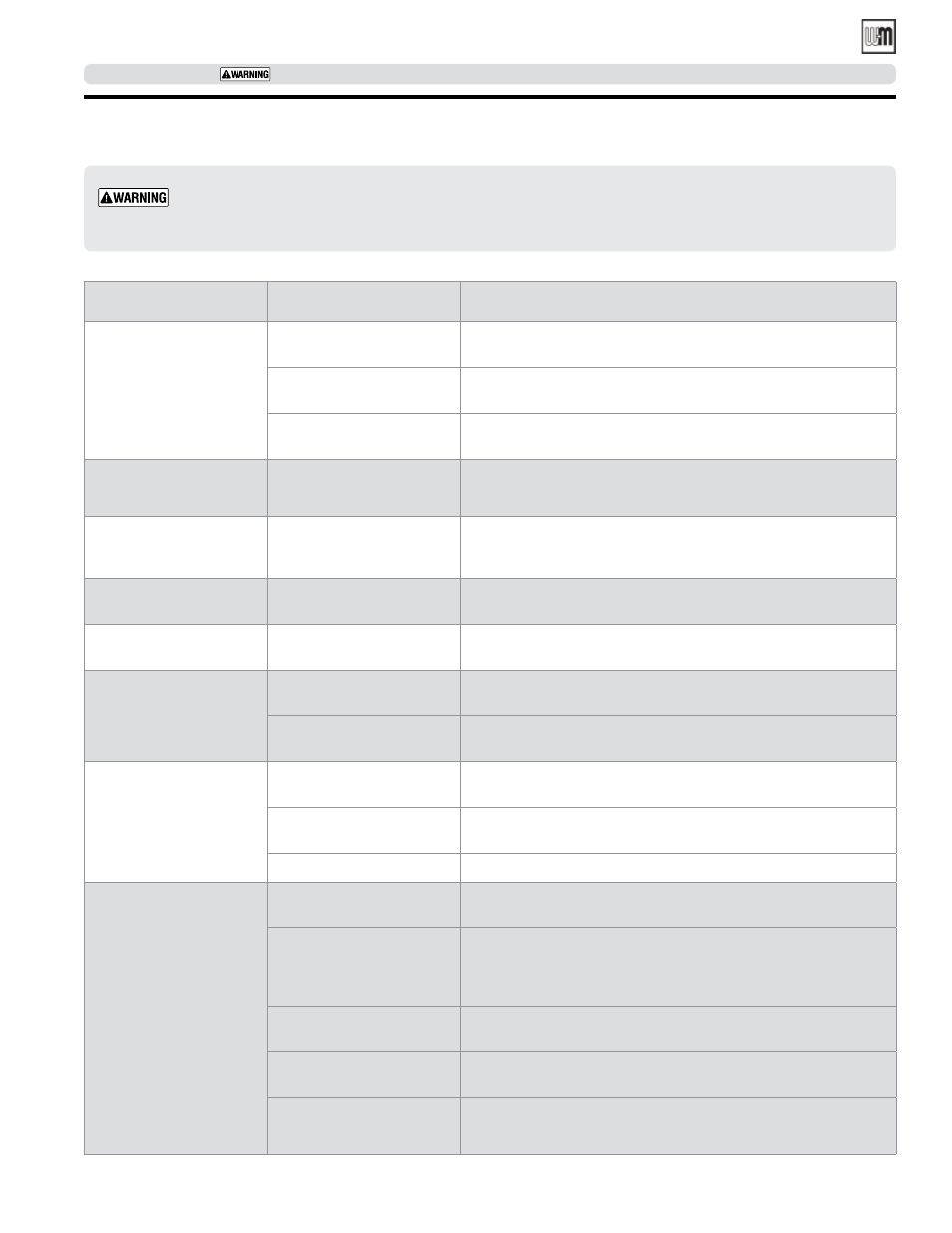

Common Problems

Common Causes

Possible Corrections

Rapid cycling — burner

turns on and off frequently.

Thermostat installed where

drafts or heat affect reading.

Locate thermostat on inner wall away from heat sources or cool drafts.

Heat anticipator in thermo-

stat adjusted incorrectly.

Adjust heat anticipator to match current draw. Refer to boiler wiring

diagram.

Incorrect limit setting.

Have qualified service technician increase limit setting to decrease

cycling. Maximum setting 220° F.

Need to frequently add

makeup water.

Leaks in boiler or piping.

Have qualified service technician repair leaks at once to avoid constant

use of makeup water.

Popping or percolating

noise heard in boiler.

Mineral deposits in sections

due to constant use of make-

up water, or incorrect pH.

Have qualified service technician de-lime boiler, repair leaks at once

to avoid constant use of makeup water and check pH (between 7.0

and 8.5).

Black water condition.

Oxygen corrosion due to

leaks in piping.

Have qualified service technician repair leaks at once to avoid constant

use of makeup water and check pH (between 7.0 and 8.5).

Frequent release of water

through relief valve.

Expansion tank sized too

small or water-logged.

Have qualified service technician check expansion tank operation.

Metal flakes found in

flueway.

Contaminated combustion

air supply.

Remove sources of hydrocarbons in or near boiler area. (Bleaches,

cleaners, chemicals, sprays, fabric softeners, paint remover, etc.)

Condensation of combustion

gases.

Have qualified service technician check boiler operation.

Some radiators or

baseboard units do not

heat or are noisy.

Air in system.

Bleed air from system through air vents in radiators or baseboard units.

Low system pressure.

Have qualified service technician check for leaks in boiler or piping

at once.

High limit set too low.

Have qualified service technician adjust limit to higher setting.

Domestic water from

tankless heater is hot then

suddenly turns cold.

OR

Domestic water from

tankless heater is always

lukewarm.

Mineral deposits insulate

internal waterways of heater.

Have qualified service technician delime or replace coil.

Boiler stop-leak compound

has been added to boiler wa-

ter and is insulating outside

of coil.

Have qualified service technician remove and clean coil and drain,

and flush boiler to remove stop-leak.

Incorrect mixing valve setting

for tankless heater.

Have qualified service technician adjust mixing valve setting.

Domestic flow rate too high. Have qualified service technician install flow check valve set to rating

of tankless heater.

Incorrect setting on tankless

heater control.

Have qualified service technician raise tankless control setting. Adjust

differential on tankless control to lower setting.

Part number 550-141-826/1211

7

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 —

Boiler Manual