Detailed service procedures, Boiler manual – Weil-McLain 550-141-826/1201 User Manual

Page 30

SERVICE TECHNICIAN ONLY — read and follow completely.

Detailed service procedures

Cleaning boiler flueways

Make sure all electrical connections to boiler are turned

off and wait until boiler is warm, not hot, before clean-

ing. Failure to do so will result in severe personal injury,

death or substantial property damage.

1. Top flue boilers -remove breeching and jacket top panel.

Rear flue boilers - remove jacket top panel.

2. Remove flue collector hood, saving hardware for reassembly.

3. Shut off oil valves. Arrange drip pans under the areas of oil piping

that will be disconnected. Disconnect oil line at burner so that you

can swing open the door completely.

4. Line combustion chamber floor with newspaper to catch any soot

that will be loosened in the cleaning process.

5. Starting at the top of the boiler, use a wire flue brush to thoroughly

clean between all pins at all angles. Be careful not to damage side

walls of rear refractory.

6. Move to the bottom of the flueways and clean up between the

sections to reach pins left uncleaned in step #5.

7. Once the flueways are cleaned, carefully remove the paper from

the floor of the combustion chamber.

8. Verify sealing rope around flue area is intact. Visually check condition and

position of insulation in combustion chamber floor, and the refractories

at the rear of boiler and in the burner mounting door. Replace any parts

as necessary.

9. Close burner mounting door and tighten nut securely. Place flue

collector hood on top of boiler. Secure with hardware from step #2.

Maintain a gas-tight seal to avoid possible flue gas leak-

age and carbon monoxide emissions, which can lead to

severe personal injury or death.

10. Check breeching for sooting and clean if necessary. Install jacket

top panel and breeching.

11. Reconnect oil line and all electrical connections.

General description of control operation

Automatic air vent

Air is released when cap is unscrewed one turn. If air vent leaks, re-

move small cap on top of vent, push in stem of valve and then release

to clean valve seat. Screw cap completely on, then unscrew one turn.

Temperature limit control

If high boiler water temperature occurs, control shuts down burner, but

allows circulator to run as long as there is a call for heat. Limit should

be set higher than temperature needed for the system.

Maximum limit setting is 220°F.

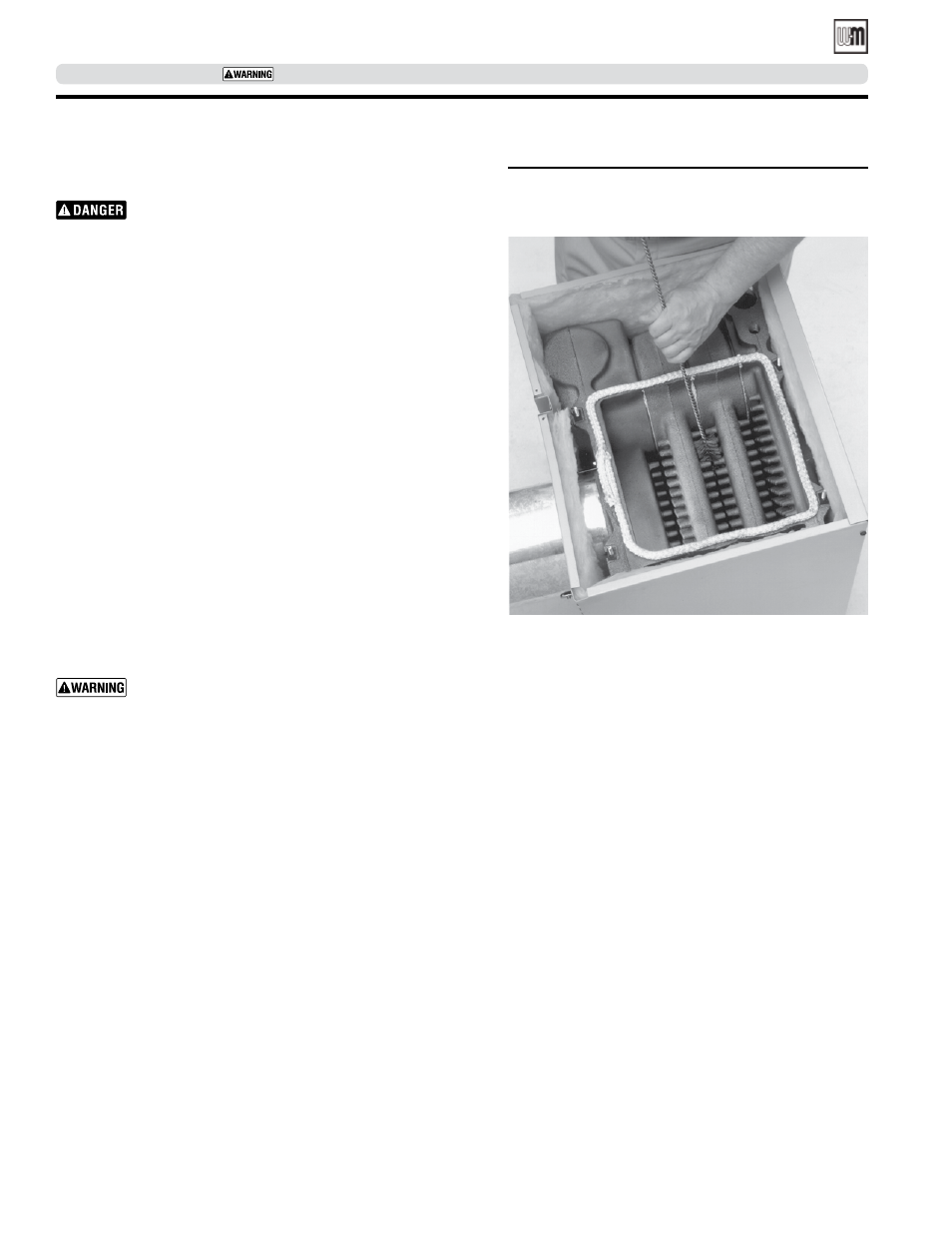

Figure 21

Thoroughly clean flueways between all pins

at all angles. Start on top of boiler, finish from

the bottom.

Water relief valve

Provides discharge if boiler pressure exceeds 30 psig.

Circulator

Circulator provides forced water circulation through boiler

and piping system.

Pressure-temperature gauge

Provides reading of boiler pressure and temperature. Maxi-

mum boiler pressure is 50 psig, maximum water tempera-

ture is 220°F. Temperature will vary according to system

and daily heating demands. The range will be from room

temperature up to limit control setting.

Part number 550-141-826/1211

30

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 —

Boiler Manual