Connect water piping, Boiler manual – Weil-McLain 550-141-826/1201 User Manual

Page 18

SERVICE TECHNICIAN ONLY — read and follow completely.

General piping information

• All packaged WGO boilers are shipped with an installed

combination temperature limit control/low water cut-off.

• If installation is to comply with ASME or Canadian

requirements, an additional high temperature limit is

needed. Install control in supply piping between boiler

and isolation valve. Set control to a minimum of 20°F

above set point of combination control. Maximum al-

lowable set point is 220°F. Wire control as shown on

wiring diagram.

• Use backflow check valve in cold water supply as required

by local codes.

Install piping

• See Figure 9 or Figure 10, page 19, and Table 4, page 18

for near-boiler piping and single-zone piping. See page 20

to complete multiple-zone piping or page 21 to complete

piping for systems operating below 140°F.

• For multiple-boiler piping, refer to Weil-McLain’s “Pri-

mary/Secondary Piping Guide” and “M-WGO Multiple

Boiler Manual.”

• Install relief valve vertically in “R1” tapping on front

of boiler. See Figure 9 or Figure 10 and also refer to tag

attached to relief valve for manufacturer’s instructions.

Pipe relief valve discharge line near floor close

to floor drain to eliminate potential of severe

burns. Do not pipe to any area where freezing

could occur. Do not plug, valve or place any

obstruction in discharge line.

DIAPHRAGM expansion tank

(Figure 9, page 19)

• Make sure expansion tank size will handle boiler and

system water volume and temperature. Tank must be

located near boiler before inlet to circulator. See tank

manufacturer’s instructions for details.

• Undersized expansion tanks cause system water to be lost

from relief valve and makeup water added through fill

valve. Eventual section failure can result.

• Install automatic air vent in “N” tapping as shown in

Figure 9.

CLOSED expansion tank

(Figure 10, page 19)

• Ensure expansion tank size will handle boiler and

system water volume and temperature.

Undersized expansion tanks cause system

water to be lost from relief valve and

makeup water added through fill valve.

Eventual section failure can result.

• Connect tank from “N” tapping shown in Figure

9 to expansion tank. Use ½" N.P.T. piping. Pitch

any horizontal piping up towards tank 1 inch per

5 feet of piping.

To connect WGO boilers to

indirect-fired water heaters

Install and wire per water heater manual provided with

water heater.

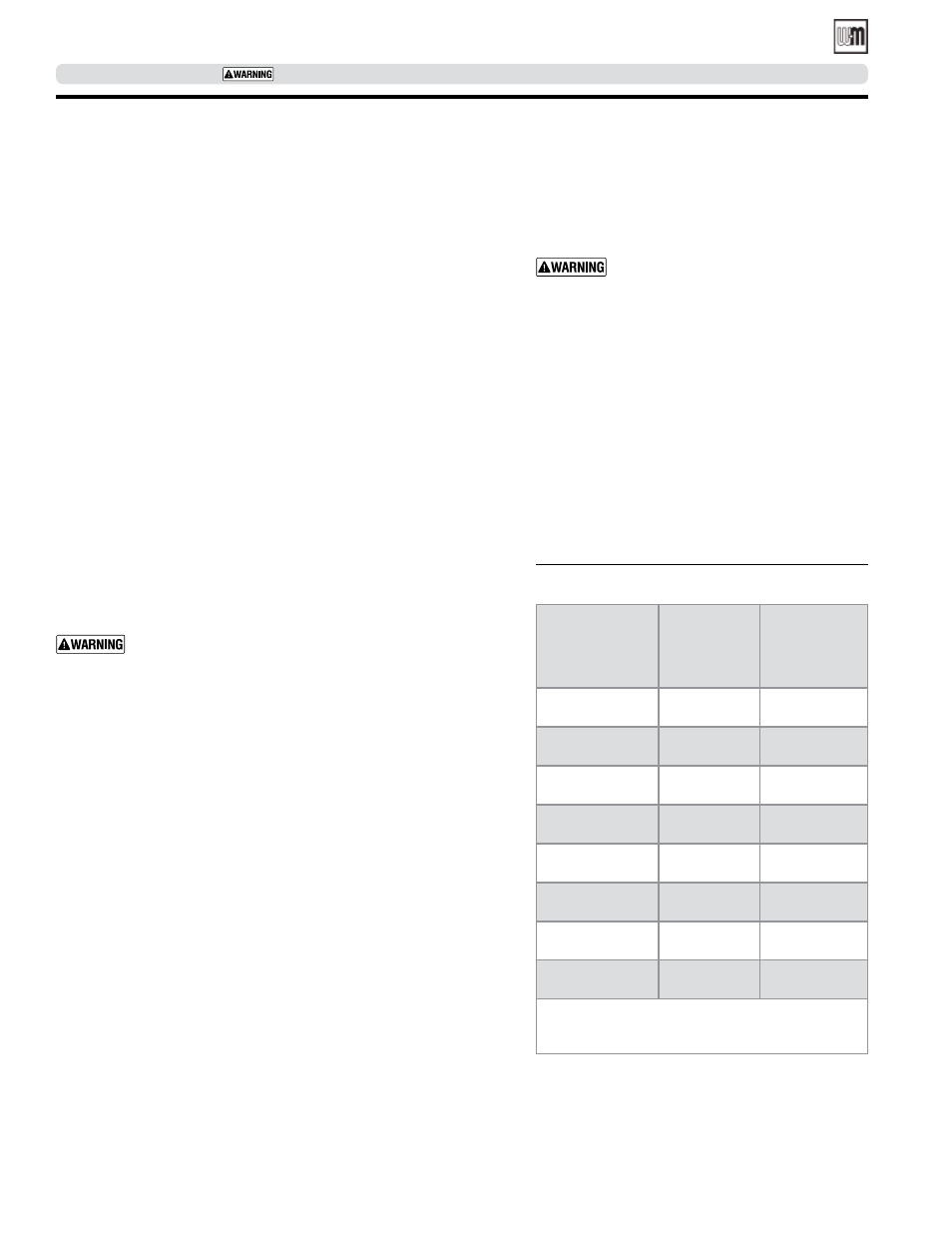

Connect water piping

Boiler model

number

To system

From system

WGO-2

1"

1"

WGO-3

1¼"

1¼"

WGO-4

1¼"

1¼"

WGO-5

1½"

1½"

WGO-6

1½"

1½"

WGO-7

1½"

1½"

WGO-8

2"

2"

WGO-9

2"

2"

* All piping sizes based on 20°F

temperature rise through boiler.

Table 4

Water piping sizes

Part number 550-141-826/1211

18

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 —

Boiler Manual