Connect oil piping, Boiler manual – Weil-McLain 550-141-826/1201 User Manual

Page 26

SERVICE TECHNICIAN ONLY — read and follow completely.

Connect oil piping

General oil piping requirements

• Location and installation of oil tanks, oil piping

and burners must follow:

• NFPA 31, Standard for the Installation of Oil-

Burning Equipment.

• In Canada, CSA B139, Installation of Oil-

Burning Equipment.

• Local codes and regulations.

• Information provided with burner and fuel

pump.

• If any part of fuel oil tank is above level of burner,

installation of an anti-siphon device is highly rec-

ommended to be used to prevent flow of oil in case

of oil line break.

• Support oil lines as required by codes.

• Make tank connections with swing joints or copper

tubing to prevent breaking in case the tank settles.

Make swing joints so they will tighten as tank settles.

Non-hardening pipe joint compounds should be

used on all threads.

Do not use Teflon tape as an oil pipe

sealant. It can cause valves to fail, creating

hazards. Do not use compression fittings.

• Underground pipe must be run in a casing to pre-

vent oil leaking into ground or under floor. Check

local codes for information.

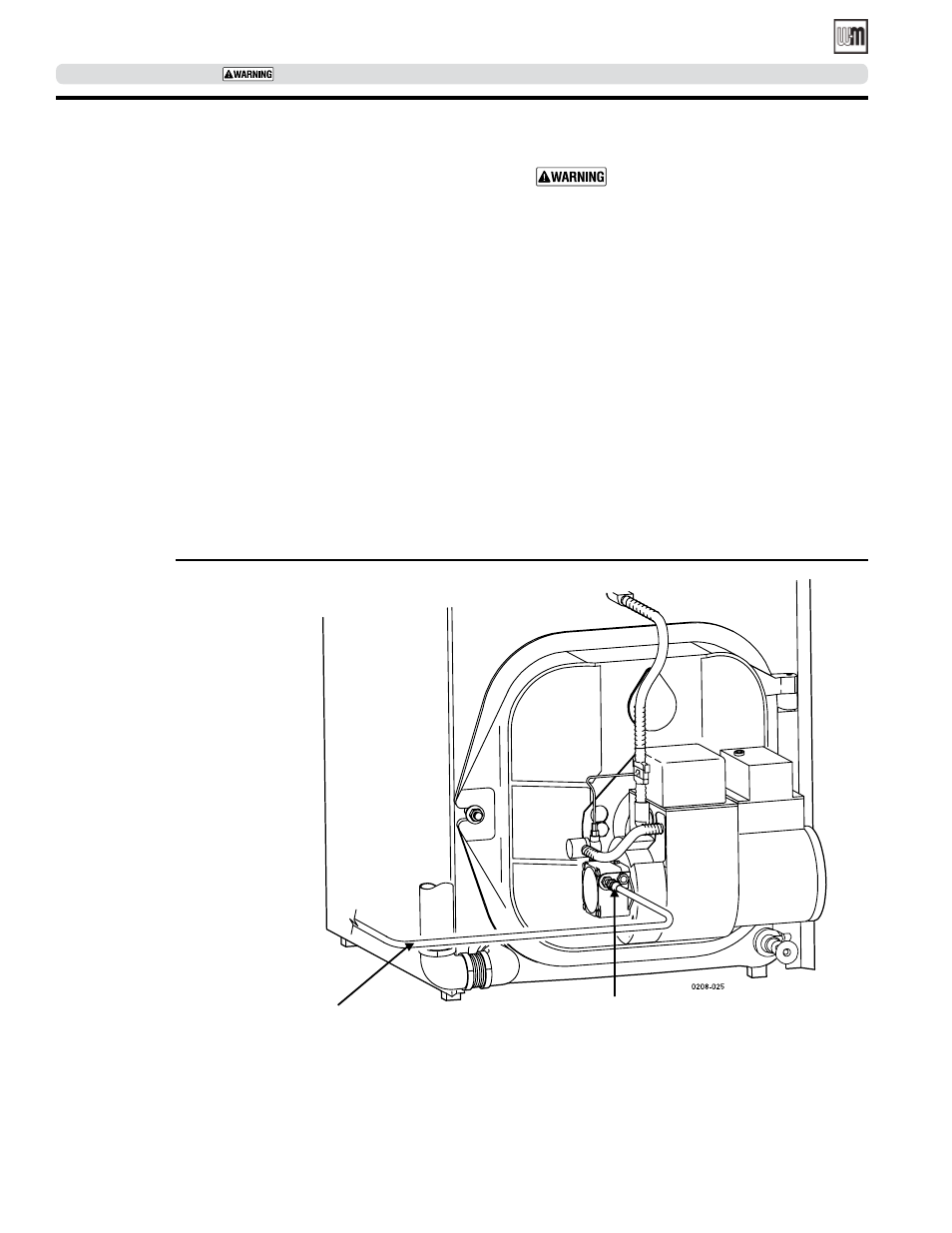

Oil piping connection at burner

See Figure 20 for recommended connection at burner,

allowing burner mounting door to swing open com-

pletely for servicing.

Figure 20

Recommended oil piping connection to burner

See local codes for

appropriate arrangement and

piping of filter control valves,

etc., back to oil tank

Flare fitting

Part number 550-141-826/1211

26

GOLD

WGO

OIL-FIRED NATURAL DRAFT WATER BOILER — SERIES 3 —

Boiler Manual