Determine boiler location, Installation & operation manual – Lochinvar KNIGHT XL 801 User Manual

Page 9

9

1

Determine boiler location

(continued)

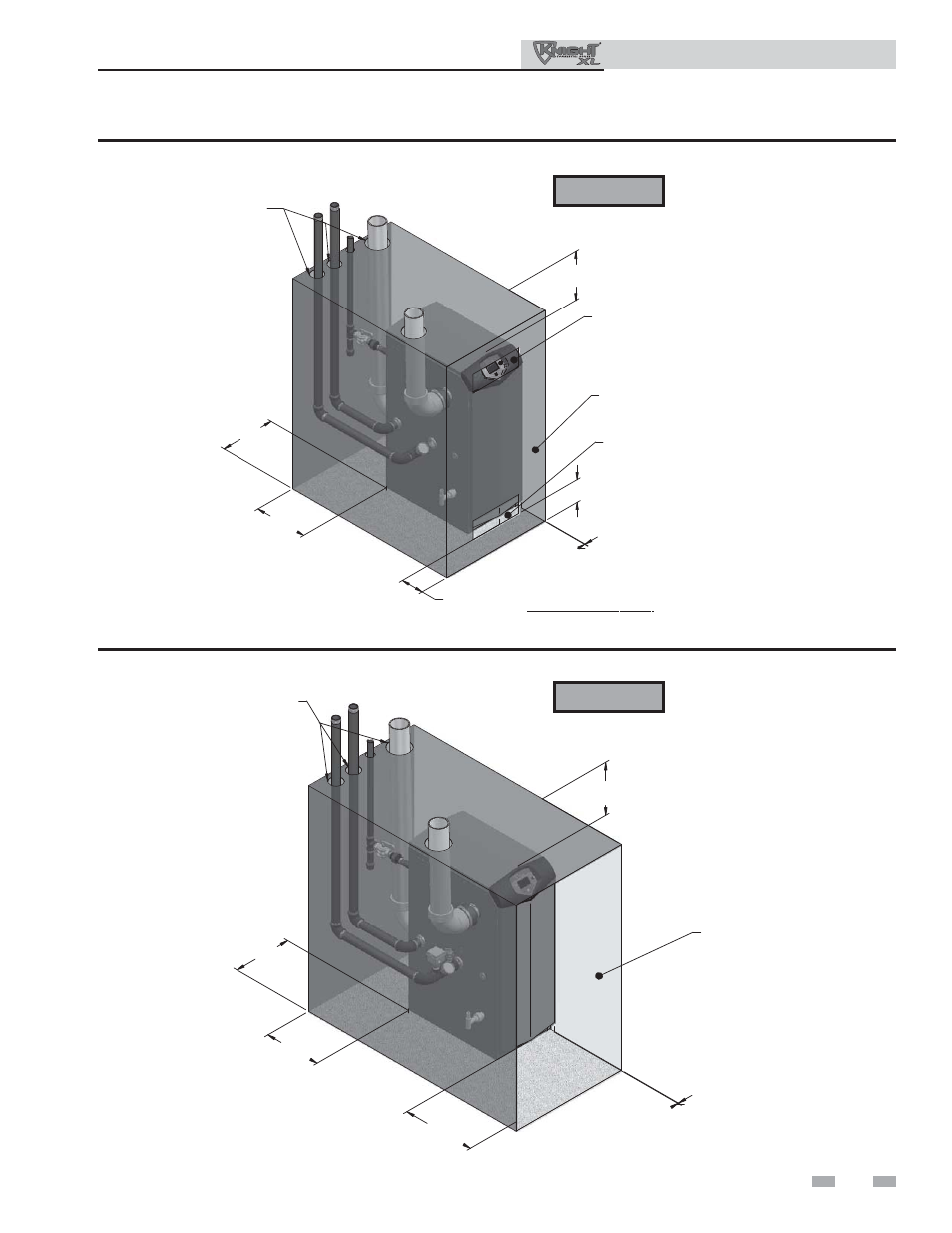

ALCOVE INSTALLATION

OPEN

FRONT

1/4" (6 MM) MINIMUM CLEARANCE

AROUND HOT WATER PIPES

1” (25 MM) MINIMUM CLEARANCE

AROUND VENT PIPE

18" (457 MM)

FRONT

0"

RIGHT

13" (330)

TOP

12"

(305 MM)

LEFT

14" (356 MM)

REAR

RECOMMENDED SERVICE CLEARANCES:

FRONT

- 30” (762 mm)

TOP

- 24” (610 mm)

LEFT SIDE - 24” (610 mm)

REAR

- 24” (610 mm)

Figure 1-2 Alcove Installation - Minimum Required Clearances

CLOSET INSTALLATION

CLOSED DOOR

VENTILATING

AIR OPENING

*

*

*

AREA OF EACH OPENING:

1 SQ. INCH PER 1000 BTU PER HOUR INPUT

WITH A MINIMUM OF 100 SQ. INCHES.

1/4" (6 MM) MINIMUM CLEARANCE

AROUND HOT WATER PIPES

1” (25 MM) MINIMUM CLEARANCE

AROUND VENT PIPE

6" (152 MM)

FRONT

6"

13"

TOP

0"

RIGHT

12"

(305 MM)

LEFT

14" (356 MM)

REAR

VENTILATING

AIR OPENING

RECOMMENDED SERVICE CLEARANCES:

FRONT

- 30” (762 mm)

TOP

- 24” (610 mm)

LEFT SIDE - 24” (610 mm)

REAR

- 24” (610 mm)

Figure 1-1 Closet Installation - Minimum Required Clearances

ƽ WARNING

For closet installations, CPVC or

stainless steel vent material MUST

BE used in a closet structure due to

elevated temperatures. Failure to

follow this warning could result in

fi re, personal injury, or death.

ƽ WARNING

For alcove installations, CPVC or

stainless steel vent material MUST

BE used in an alcove structure due

to elevated temperatures. Failure to

follow this warning could result in

fi re, personal injury, or death.

Installation & Operation Manual